Diesel of the Week is presented by

With a dad who owned a repair shop, Dustin Harrison grew up as a gearhead, and would try to make everything faster, better and louder, as most gearheads do. When the diesel aftermarket first started to surge in the late-‘90s and early 2000s, Harrison was just getting his driver’s license. His first truck? It was a diesel, and his passion for diesel trucks and engines blossomed from there.

“I had the automotive background and I applied that to the diesel side, and because there weren’t a lot of shops doing diesel performance at that point, we started working on a lot of diesels,” Harrison says. “I opened Apex Diesel Performance five years ago in 2014.”

Apex Diesel Performance has four full-time employees operating out of an 8,700 sq.-ft. facility in Atlantic, PA. The Apex shop is strictly dedicated to diesel engine work and machining, and also has a Land & Sea dyno.

Apex Diesel has plenty of in-house capabilities, but the guys at the shop can also make a 10-minute drive down the road where they utilize a local CNC shop for one-off pieces too.

“We do high performance sled pulling and drag racing turbo work,” Harrison says. “On the engine side, we mainly do Cummins engines – 12 valve, 24 valve and common rail, with the 5.9L and 6.7L being the most common builds. We do a few Powerstroke builds, but we’re close to 100% Cummins engines. With the workload and volume of stuff that we have, it’s easier keeping machines set up for the inline six engines and the inline six heads.”

Apex Diesel Performance’s latest and greatest build the shop recently finished is a big, single charger, Super Stock 6.7L Cummins engine.

The sled pulling engine build started with a 6.7L Cummins factory block and the shop added a one-inch deck plate and ductile iron Power Bore cylinder sleeves.

“We use [Power Bore] strictly for all of our 6.7s, even if we don’t use a deck plate,” he says. “A 6.7 bore is 4.210˝, and we’ll actually sleeve it back to a 4.125˝ bore. The sleeves work pretty well and we haven’t had any failures or cracks. The factory machines the block and we clearance the bottom of the liners and the inside of the block a little bit for the longer rods and the rotating assembly with the smaller bore size. If we don’t, we get into a little bit of clearancing issues there.”

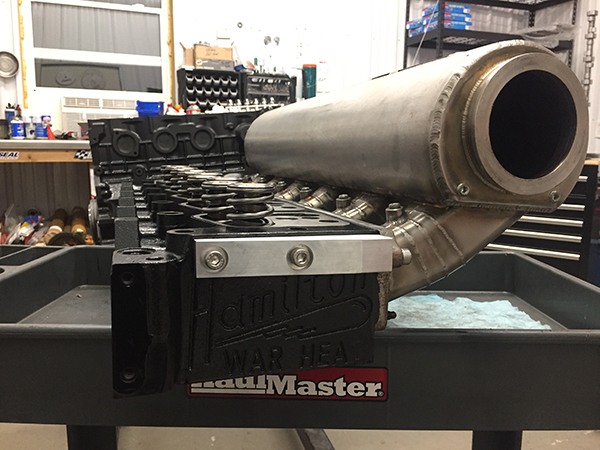

The shop uses a factory crankshaft as well, which is a 4.880˝ stroke and is extremely strong and a good design right out of the box, according to Harrison. The shop also opts to use the ‘old school,’ 12-valve cylinder head, which is a Hamilton Cam’s aftermarket casting.

“We make our own bottom end girdle too – a 14 millimeter, one-piece, bottom end girdle,” he says. “It’s the same thing with the top – a 14 millimeter ARP 625 head stud. They hold up pretty good and we don’t usually have any firing or head gasket trouble out of them, which for the boost and the cylinder pressure we run is pretty impressive. This set up makes about 120 pounds of pressure on just a single charger.

“We also make our own billet rods, which are custom, one-inch longer, triple-beam rods. These are similar to the H-beams, but we add a third beam in the center of the connecting rod. We modify the block for roller cam bearings and we modify the lifter bores to accept a roller lifter instead of the factory flat tappet style. We run a Crower keyed lifter and a bronze bushing in the lifter bores.”

For this build, Apex runs tool steel wrist pins and tool steel, solid pushrods due to the cylinder pressure and the spring pressure of the engine.

“We’re running into a little bit of deflection and clearance issues in the cylinder head because with the really high lift, high duration camshafts we run, you can only clearance the head so far, so you can’t get a real big pushrod in them,” Harrison says. “So we stay with a smaller, tool steel, Top Fuel dragster, pushrod and stay with a smaller diameter. We get those from Manton.”

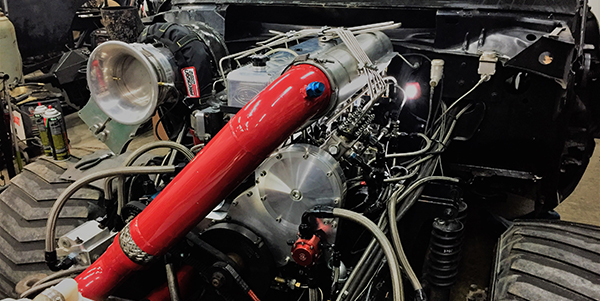

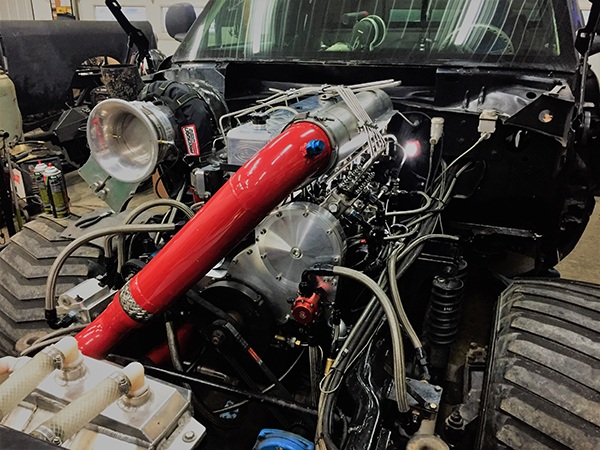

The 6.7 Cummins also gets equipped with Arias forged pistons, a Fluidampr, a billet roller rocker system for better valvetrain geometry, Clevite coated bearings, a 17mm Hypermax Sigma pump, Sheid Diesel injectors, and a wet sump, R&R external, three-stage oiling system.

To cap off the build, Apex has a 4.5˝ ball bearing, billet center section HX82 turbocharger on the 6.7.

“On the dyno, the 6.7L Cummins made just over 2,800 horsepower,” Harrison says. “We’re about one to one horsepower and torque.”

The Diesel of the Week eNewsletter is sponsored by AMSOIL.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].