E-commerce is here to stay, and with the tremendous growth in this industry comes a fundamental shift in shipping and delivery. The pattern of single trucks that deliver large shipments to a final, central location is being replaced by a dynamic system in which those large loads are fragmented, and goods are then delivered individually to end-users. This additional step in the delivery process is known as “last mile delivery,” although that final “mile” could be dozens of miles or just several blocks.

Last mile delivery is focused on delivering items to the single end user as quickly as possible, and it’s set to support both growth and increased profits for any shipper ready to take advantage of the trend. For fleet and repair shop owners, that can mean being prepared to deal with the consequences of stop-and-go driving and extended idling periods. Expecting these challenges and meeting them head-on will ensure a solid place in this quickly-growing market.

As shippers adjust to the new set of on-the-road demands entailed in last mile delivery, they are looking to smaller, more agile and fuel-efficient options than Class 5, 6, 7 and 8 vehicles. For example, Fleetio reports that smaller trucking companies are expanding their fleets by adding cargo and Sprinter vans in order to carry out e-commerce deliveries.

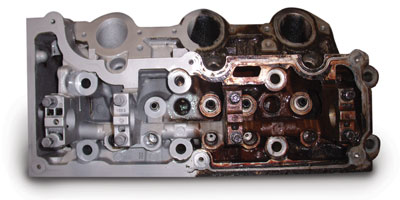

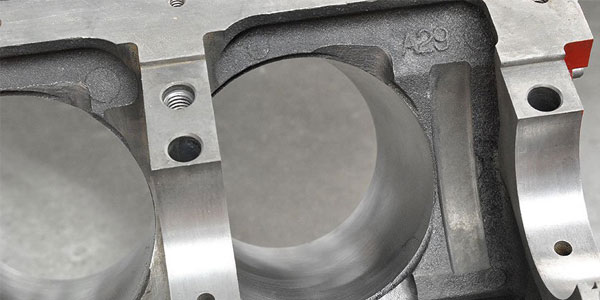

With the dramatic rise in delivery van popularity and utilization comes the necessity to service these hard-working fleet vehicles. The increased stress placed on all van systems means that downtime is almost inevitable. Yet downtime costs owners beyond the price of the repair, so getting back on the road quickly, with quality parts, is essential.

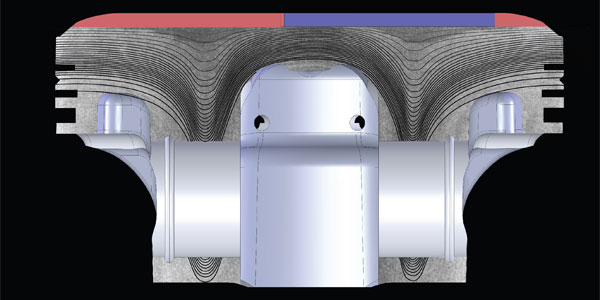

Although they are relatively small in size and overall expenditure, gaskets are absolutely crucial to lasting repairs. When it comes to gaskets and sealing products, Victor Reinz is a brand that repair shop and fleet owners can trust. Dana has been supplying Victor Reinz gaskets to original equipment manufacturers for decades, and supports aftermarket distribution around the world.

Fleet and service shop owners will appreciate the completeness of the gasket sets offered by Victor Reinz, and the coverage available for a range of Class 1, 2, 3 and 4 vehicles. Head gasket applications include popular delivery vehicle engines such as the Cummins, the Powerstroke, and the Duramax with patented Wave-Stopper Technology. As the last mile delivery market grows, Victor Reinz is committed to providing coverage and continuing to respond to market demands.

Victor Reinz gasket sets and sealing products are backed and distributed by Dana Incorporated. Dana provides the parts that drive the aftermarket vehicle industry – and that help you deliver to the last mile.

This article was sponsored by Victor Reinz. For more information on Victor Reinz gasket kits and sealing solutions, visit victorreinz.us/lastmile.