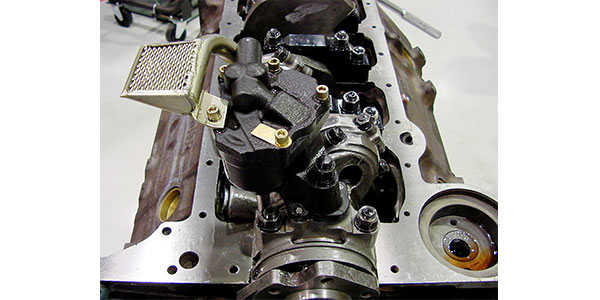

A stock pump may be just fine for some mild performance, and it may even produce enough pressure for a wilder application, but the limitations are mostly from the housings themselves, which can vibrate and crack at high rpm or under heavy loads. While many engine builders continue to use the shaft-style pumps in SBC and other applications, newer-style engines have moved toward everything from front-mounted pumps to variable displacement and dry sump systems. We’ll take a look at the systems to help you determine the best fit for your next build.

The old rule of thumb says engines need about 10 psi of oil pressure for every 1,000 rpm. Today, many pros are running less pressure to reduce the horsepower loss.

According to Cale Risinger, technical service manager for Melling, a wet sump can perform as well as a dry sump in some instances. But a wet sump pump has efficiency limitations at very high rpms, he says. These can be easily overcome on a dry sump by adjusting pump speed.

Whether you use a standard-volume pump, or a high-volume pump can vary, according to our experts. But applications where you are using tighter bearing clearances and a light-viscosity oil, it’s best to use a replacement pump with an output comparable to the original equipment pump. If you’re running piston oilers or VVT where you need more oil flow for cooling and cylinder deactivation, a high-volume pump would be necessary to keep up with the oil demands. Otherwise, for standard builds or builds for a spec class, a standard-volume pump is going to provide enough flow and pressure.

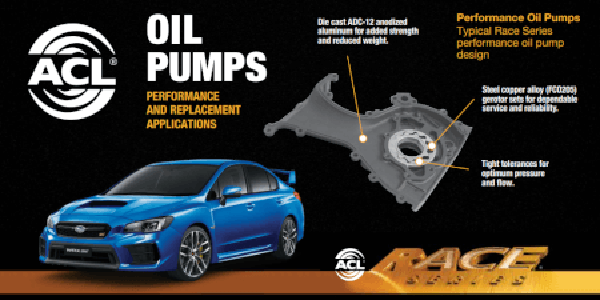

Performance pumps can offer more features and help engines survive in racing or more demanding applications, which is why Risinger suggests engine builders should consider upgrading to a performance pump any time a performance engine is being built. Most of these units are available in standard or high volume but include stronger housings and redesigned ports for better oil flow.

“We’re seeing some circle track racers switch from dry sump oil systems back to our billet wet sump oil pump,” says Risinger. “It’s a lot less expensive than a dry sump system; and it’s lighter, reliable and simple to install.”

A high-volume oil pump uses taller gears for more displacement so it can flow more oil per minute than a stock pump – around 10 to 25 percent more, depending on the application. A high-volume pump, as the name suggests, will move a higher volume of oil through the same clearance, which raises the operating oil pressure in the engine over a standard volume pump.

Baker Engineering’s TJ Grimes says that a high volume is not always needed. “An aftermarket block with prior main oiling and very close tolerances might only need the stock flow rate or even less. A high-volume pump just moves more volume for applications that need it. For example. it works well for factory blocks and applications that may see a lot of low speed operation through its life.”

The engine oiling system is a leak-type system by design, according to Risinger. “An engine with bigger bearing clearances would need a high-volume pump; you also need to look at any additional oiling demands such as piston oilers, valve train sprayers, external oil cooler, external oil filters, etc.”

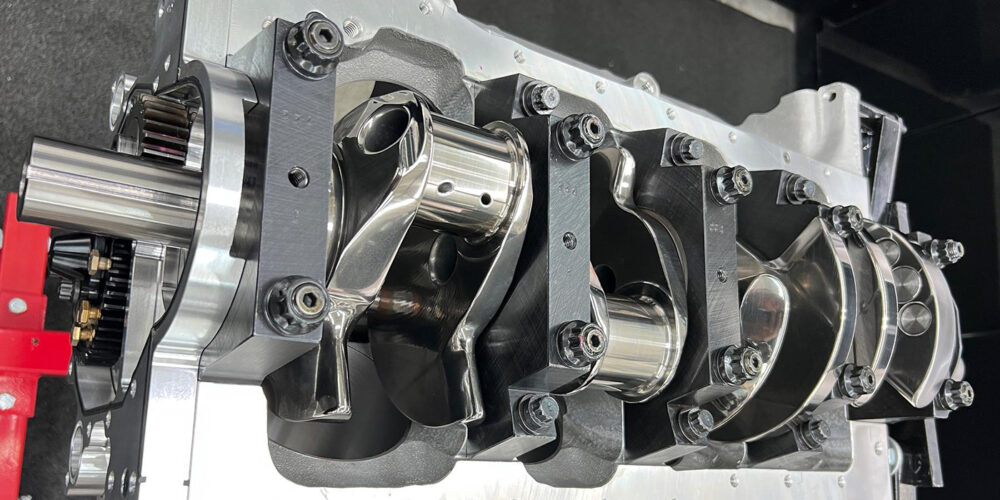

Most performance pumps have a heavy-duty pump body – either a beefed-up cast-iron version or billet – with supported shafts into the pump cover to eliminate gear deflection at higher rpms, as well as multiple bypass pressure options. In addition, many of the performance pumps also use a different gear design, or material, such as billet aluminum oil pumps for the big and small block V8s. The pumps are pan-specific, and the billet versions include an integrated pickup design for both street strip models as well as circle track options.

Several aftermarket manufacturers offer performance upgraded oil pumps for the most popular engine applications such as SBC, LS, Ford Modular or Chrysler Hemi in a variety of styles that feature high volume to billet.

Melling, for example, offers a performance SBC pump designed to reduce cavitation with the addition of grooves that are machined into the housing and cover. The grooves minimize cavitation effects in high rpm situations. Some of these pumps extend the shaft through the gears, so the gears are supported at both ends. This prevents the gears from deflecting under load and dragging against the cover, which can rob horsepower and increase wear (not to mention the pressure losses).

The old school rule of thumb says that most engines need about 10 psi of oil pressure for every 1,000 rpm. For the grassroots level racer, being on the conservative side will get you to the finish and perhaps extend the rebuild a few more races. But many pros are now running significantly less pressure (up to 40 percent less) to reduce the horsepower loss needed to drive the oil pump. The only way to get away with this is to run tighter bearing clearances and have enough oil volume to keep everything well lubricated.

Dry Sump

A high-end billet dry sump pump can cost thousands of dollars. But if money is not a concern, and you don’t have space constraints to contend with, then a dry sump system is almost always the way to go to ensure proper lubrication without risking oil starvation. Dry sump oil pans are also available for many popular engines and rely on oil scavenge pumps to circulate the oil from the pan to the tank and back. On a dry sump system, the pump’s output routes directly to the crankshaft bearings. Oil can also be directed up top to lubricate the valvetrain and turbocharger if necessary.

While there are many performance upgraded oil pumps on the market, we recommend choosing a brand that is quality made. A good performance pump should come with either thicker castings or use higher-grade alloys to increase strength and durability.

Most 3-stage dry sump systems do not have enough suction to pull vacuum on their own, so if you want to minimize windage and parasitic losses, many engine builders choose to go with a 4-stage, 5-stage or 6-stage setup. A good rule to remember is that bigger engines need more scavenging to pull vacuum in the crankcase.

Variable Displacement

A newer-style oil pump being used by more and more OEMs is a variable-displacement style that controls how hard the pump works by matching the pressure and volume to the conditions. Melling’s Risinger says they have been working with these pumps for a few years on the OE side, but are just starting to test them for aftermarket applications. The obvious advantages are that you can control the volume by engine temperature, load or engine speed through the ECU.

Another benefit of controlling the oil pressure and volume is for thermal management. By regulating the oil volume, heat transfer can be optimized in the head and the pistons. Almost every major OEM is using some form of a variable displacement oil pump on late model engines. Whether it is controlled by a spring (such as on the LS) or ECM, you will most likely see them in performance applications soon because they can produce better pressure and efficiency, which should mean more power.

Pans & Screens

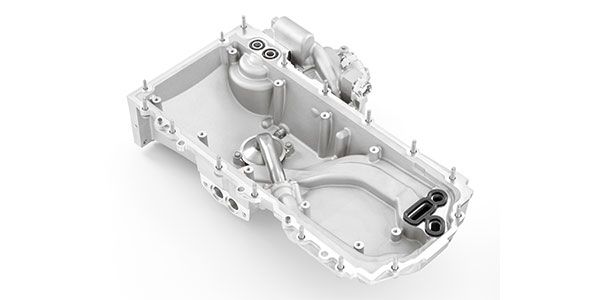

An oil pan with extra oil capacity is an excellent addition to any performance or race engine (if rules allow). To cut down the chances of oil starvation and loss of oil pressure, you need more oil in the pan, but it must be designed to keep the oil where the pickup is always submerged in oil unless it is a dry sump system. Most racing and performance pans use an elaborate array of baffles and one-way trap doors to control how the oil sloshes around under acceleration, braking and cornering. Other features include side kickouts to hold oil in the pan until it is needed under heavy g-forces such as cornering or braking.

According to Grimes, different types of racing will drive the design by how the oil needs to be controlled in the sump. “In a drag racing application, you are primarily concerned with acceleration and deceleration. Circle track and road racing certainly increase the level of difficulty in oil control. Windage can rob horsepower, drive oil temps up and even lead to aeration of the oil until you run into some serious problems like pump cavitation and loss of pressure.”

Some engine builders weld the pickup tubes on SBC pumps in place with a metal box on the bottom that has drilled holes instead of a traditional screen. But if the holes are too small, it may not allow enough oil flow. Grimes says that race engines need minimal filtering at the screen with larger openings so as not to starve the pump’s oil supply. You also need to locate the tube in the correct position so it’s far enough above the bottom of the pan that it doesn’t restrict flow, but not too high so it doesn’t suck any air during cornering, braking or acceleration.

Moroso’s Drag Race oil pan for the COPO Camaro is a good example of a race-specific pan. It’s a 7-1/2˝ deep aluminum oil pan that features a trap door baffle assembly, anti-climb baffle, and anti-slosh baffle to keep oil contained in the oil pump pickup area during drag racing. The pan also has a billet aluminum rail with a fabricated aluminum sump and clears 4.250˝ stroke with most steel rods. It also includes a billet aluminum adapter that allows an OEM oil filter to be mounted in the stock location without the need to run a remote oil filter.

“Pan capacity has to be large enough to maintain sufficient oil to the pick-up for every application,” says Grimes. “A small block Chevy circle track pans hold about 8 quarts in the sump, and that is good for an 8,000-rpm engine.”

While there are many performance upgraded oil pumps and pans on the market, we recommend choosing a known brand that is quality made and beware of unknown parts from the internet. A good performance pump should come with either thicker castings or use higher-grade alloys to increase strength and durability. Using an upgraded pan made from stronger materials is also worth the expense for racers who want to make it to the finish line and keep their engine alive for more of the season.