CLEAR COAT IT TO SHOW IT

After magnafluxing, cover the magpowder in the crack with a couple coats of clear paint to retainer the powder. This works much better for showing the parts’ owner. You won’t have to magnaflux the part again for them to see the problem.

Terry Kiehnau

Terry’s Rebuilding, LLC

Green Bay, WI

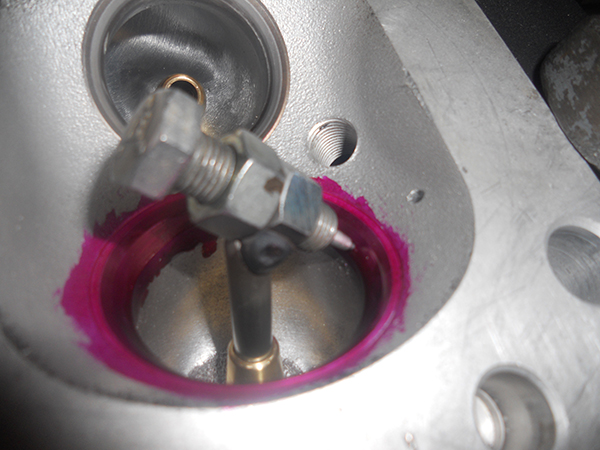

CARBIDE SCRIBE

My head porter and I developed this tool to keep all valve job bowl cuts identical. It’s very simple to make and quickly scribes exactly where to make cuts. The scribe is made from a carbide point from pocket metal scribe. It is epoxied into a drilled hole in the adjusting screw. An assortment of cut valve stems allow the tool to be used in a variety of different guides.

Eric Gartner

Performance Off Road

Shadyside, OH

ROD ALIGNMENT PINS

I like to check rod alignment before I install the pistons. I had SB and BB Chevy piston pins centerless ground .0025˝ under some years ago. Since then, I have chucked other sizes short and ground them in the crank grinder slightly under size. I believe it is more accurate than checking with the pistons on the rods.

Randy Torvinen

Torvinen’s Machine

Menahga, MN

NOT JUST FOR SHAVING

Many cylinder heads have corrosion in the water jackets that can’t all be blasted or blown out. Marine engines can be the worst. When assembling an engine, to make sure you don’t accidentally drop any loose scale in the bores, simply pump shaving cream foam into the water jackets of the head. It won’t affect anything and will evaporate off or rinse out. For guys sending heads out the door that have a corrosion problem, tape off all the water jackets for transit. The tape will grab any loose flakes. Instruct the installer to do the shaving cream trick. Some applications require some excessive handling to get the head on the block and this will save you from shortblock contamination.

Ron Flood

Cedar Machine

North Branch, MN

I’VE SEEN THE LIGHT

Once again, I found myself on a ladder, one leg on the top rung and the other on a shelving rack, struggling to replace a ballast that was sucking the life out of our light and our electric bill. You’ve been there, trying to hold the swinging fixture while unbolting and rebolting the replacement ballast… wondering, “who invented that little flat square nut?”

Those old T12 (and T8), 8’ shielded fixtures reside in just about every machine shop I visit. These workhorses provide bright “outdoor” light for a fraction of the operating expense of the incandescent bulbs of the past. But today, there is something much better – LEDs. I discovered a new type of replacement that is easier to install, provides brighter light, lasts two to three times longer than Ts (up to 50,000 hours), and will reduce electrical costs by 30%-50%. Eight-foot LED type-B bulbs fit in your existing fixture, and they run off direct current so you bypass the energy-sucking ballast. The Type-B bulbs are pricey at around $20-bucks each, but when you factor-in the cost of the ballast, plus T8/12 bulbs, plus energy, plus future maintenance, it is a good value. In addition to brighter light, you’ll never have to swap a ballast in that fixture again – ever! So, the next time your light is flickering due to a bad ballast, consider eliminating the ballast and replace with Type-B LED.

Steve Rich

Sterling Bearing Inc.

N. Kansas City, MO