Your customer wants a transmission rebuild – now what?

Friday night. The local cruise-in. Amidst the Beach Boys blaring on the loudspeaker and the smell of fresh-grilled burgers, the cars pull in and the hoods go up. Whatcha got under there?

This is where it starts for a lot of us, and it’s the engine that everyone wants to know about. Horsepower is awesome and the engine is king, right? After all, when was the last time you saw fender badging that said 4L80E or C6?

I think you see what I’m getting at, and admittedly, I’m guilty of it too. I’ll be the first to blurt out what’s under the hood and leave the poor transmission without a mention. Perhaps that’s ok, because let’s face it, the engine is the heart of any performance car. However, with experience comes the understanding that building a car means building it as a whole.

We all know that, but your customers may not. Many of them overlook the transmission, right up to the point where their Friday night antics end abruptly as they coast to the side of the road.

It’s inevitable, and probably already common that your customers will ask you about rebuilding or building their automatic transmission. For some reason automatics can be intimidating, and most of us can probably cite more bad experiences than good when it comes to rebuilding, so what do you tell your customers when they ask about it? Quite often they want a recommendation too – who, where, what brand, what kind?

The answers are closer than you think, and they are a reflection of what you do. Do you ever ask yourself why people, namely your customers, bring their engine to you to build? The answer is simple. They want it done right and that’s the reason you’re in this business; you know how to do it right.

When someone comes in and wants an engine built, where do you start? Whether it’s the Friday night cruisers or the real racers, before you build something for them, you start with questions. You need to know about the car, the weight, the transmission, the type of racing or driving and all the other factors that affect how you build their engine.

Your job at this point can be easy or tough depending on how much they know, but either way, it simply comes down to educating them and guiding them along the correct path.

An experienced transmission builder will do the same thing; start with questions, lead into education and guide their customers along the correct path.

You know it’s coming. Your customer is going to hit you with the transmission pop quiz: Do I rebuild my transmission, or do I buy a rebuilt unit? What brand should I buy? Where do I get it? Do you know anyone good? And it’s a good possibility they are going to ask you about getting one online – where there are many shops, rebuilders and parts warehouses, all offering different warranties and claims of performance and durability. So the next time you’re on the spot for advice, here’s a rundown that will help you send your customers in the right direction.

An online parts warehouse or mass distributor may be the easiest option, but just as your customers come to you to build their engine, a transmission shop is a good recommendation. In this context, however, “transmission shop” requires defining. That doesn’t mean your customer can’t do research online and use a transmission builders’ website for information, and it doesn’t mean they have to be right around the corner. What it does mean is that they have to make sure there isn’t a black hole at the end of the line.

A transmission builder is going to ask almost the same questions as you prior to building an engine. The difference is instead of asking about the car, gear ratio, tire size, and transmission, they are going to ask about the car, gear ratio, tire size and engine. They need to know what kind of power the transmission needs to handle and when it needs to handle it. They’ll use their experience from that point to recommend the type of transmission and the components required to build it.

Good communication is an absolute must. Regardless of where they are located, speaking with a transmission builder is an important first step. This how you start a relationship with them and develop an initial assessment of their ability as well as their focus on customer service.

If you get a good feeling about their service and what they offer, you’ll most likely have a good experience. Online information easily makes claims about performance and durability, but if there’s no one on the other end of the line, beware. An experienced builder is going to ask all the aforementioned questions and more. You should be left with absolute confidence in their ability.

Establishing this type of relationship is equally as important in the event that you have questions or experience trouble with the installation. They have most likely seen any problems you run across, and it’s important to know they’ll back you up.

One such builder who has proven the success of customer relationships is GearStar Performance Transmission in Akron, OH. GearStar was started with the goal of building the best, high-performance transmissions, designed to meet the individual needs of their customers. A very unique approach was taken, with the focus on not only quality, but communication and interaction with the customer.

When a customer has a transmission built, they speak with the technician from start to finish. The same tech builds and tests the transmission, as well as offers any support that may be required during installation. There is a strong sense of pride and quality that goes into their work, and their success is proof of both their quality and their customer approach. “We built GearStar on word of mouth,” says Zack Farah, owner of GearStar Performance Transmissions.

When your customer has a transmission that needs built, whether it has already failed or they are being proactive to avoid that possibility, a common question is do they rebuild their unit, or just use it for the core? Of course, if it’s an all-original muscle car, they’re going to want to use the original to keep the factory date codes and stampings, but that aside, what’s the best option?

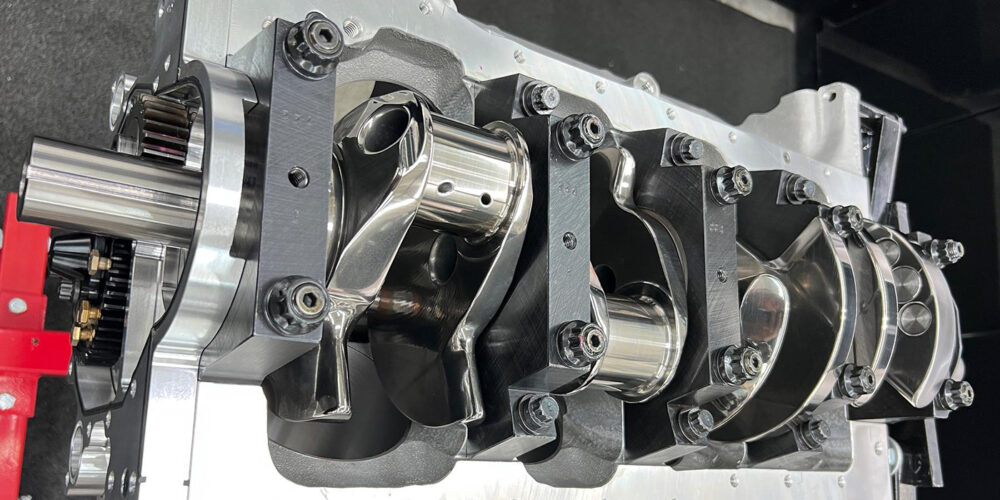

There are two things to consider. One, just like with an engine, parts that wear in together work best when they are kept together, and a transmission is no exception. If you order a mass-produced unit, do you know this is the case? Can you actually speak with the person who built it? When any transmission is torn down, all components should be kept together for that unit, and you should be able to confirm that with your builder.

Two, cleanliness is king. How are they cleaning the cases? What is the shop like? Is it a clean atmosphere? It’s a fact that transmissions are cleanest when they are new. The more they are taken apart and rebuilt, the more contamination gets inside. The fluid is the life blood of the automatic and it affects every single aspect of transmission longevity and performance. Any contamination gets carried by the fluid…everywhere.

There is no such thing as too clean in this process, and along the same lines, transmission coolers should be flushed or replaced when installing a new transmission. If there is even the slightest doubt of cooler condition, replace it, even if it’s part of the radiator. It’s a small price to pay.

An experienced builder knows the common failure points with any transmission and knows what main components to replace so the transmission will stand up to the horsepower put in front of it. They are also going to use high quality bands, clutches and seals. If they are standing behind their work and their reputation, they’re not going to use anything that will jeopardize it. A transmission builder with experience should be able to tell you all of the weak points of your transmission and what is done to remedy the problem.

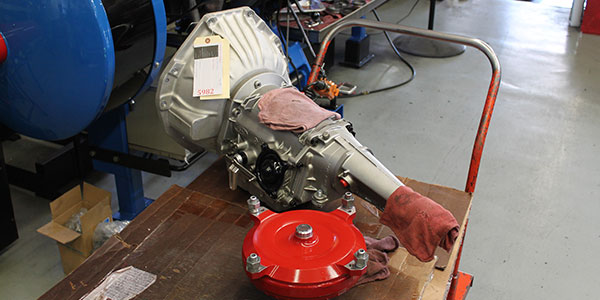

Torque converters are another subject. A torque converter is to a transmission as a camshaft is to an engine. If it’s not the right one, it just will not perform. Like the transmission itself, beware of mass-produced units, custom built is best, and a visual inspection for the appearance of quality quite often is an accurate indication of that very thing.

Not only must a torque convertor be designed and built for a specific stall speed, but they are susceptible in their own way to failure when subjected to high horsepower. Internal components must be able to handle the extreme abuse they see, and a custom build is the only way to guarantee performance and the only way to know what’s inside. Special equipment is required to build torque converters, and a shop that does it in-house is one more way to know you are getting what you pay for. A new torque convertor with a new transmission is an absolute requirement.

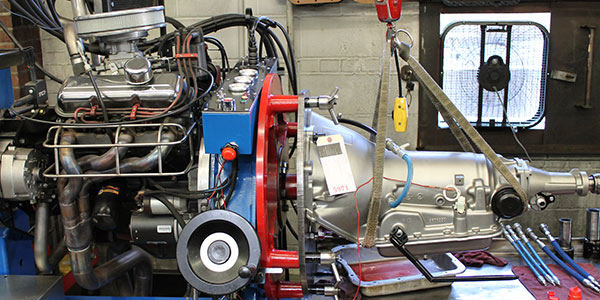

Everybody loves to hear the word dyno. “It’s dyno tested.” Is it really, or is it marketing? The only way to guarantee the correct operation of every transmission is to run it on a dyno to check for proper operation, line and throttle pressure, shift points, downshift operation, stall speed, convertor lockup and unwanted noise and leaks.

Beware of a mass builder or rebuilder that may have dynoed one transmission just to claim it in advertising. Serious builders will document and provide all dyno results for your transmission, and in some cases even provide a video of it in the process. This is the ultimate quality check of their work. This is also part of the service at GearStar Performance Transmissions, ensuring the quality of the work. “Nobody wants a transmission to come back,” Farah says.

If you have established good communication with a transmission builder, you most likely already feel comfortable with them, but it never hurts to look for customer reviews. The typical one-line online review can be tricky to decipher, and four or five stars don’t often reflect long-term results or an accurate indication of quality. Look for reviews from customers who brag about quality and customer service. You’ll see their enthusiasm for a quality job.

If a lot of this sounds familiar, it should be. It’s similar to the interaction you as an engine builder have with your customers. You take intense pride in your work and you want your customers on the street or on the strip to get maximum performance and bring their repeat business back to you. Transmission building is a perfect reflection of these ideals, so the next time a customer asks you about their transmission, you’ll automatically be able to head them in the right direction – if you don’t do it yourself.