Diesel of the Week is presented by

Rich Strube first gained an interest in engine work when he was just 19, tinkering with small block and big block Chevys, as those engines were a dime a dozen. It wasn’t until he took a job at an International dealership in the early 2000s that he fell in love with diesels.

“I got turned onto the Duramax especially,” Strube says. “The Duramax was a GM product and it resembled the small block and big block Chevrolets of the past. Duramax are most definitely my favorite platform. There’s a line of GM roots driving that decision, but it was also one of the most infrequently used engines because of the complexity behind the design. A lot of technicians were not so apt to work on the Duramax over a Cummins or the earlier Powerstrokes, which are obviously much simpler than the Duramax was.

“When the common rail hit the market, it was a very different technology. Everybody wanted to stick with the mechanicals because it was a lot easier to progress with power. The common rails required much more electronic tuning and a complete different approach with a much different foundation.”

Strube’s desire to focus on Duramax engines led him to open Richie’s Truck & Auto in 2002. The shop was literally in his backyard, but he wouldn’t have to stay there for long.

“We used to do a little bit of everything – trucks and cars – because diesels weren’t always as big as they are now,” Strube says. “That evolved into Richie’s Diesel Performance.”

Richie’s Diesel Performance is Strube’s 5,000 sq.-ft. shop in Hicksville, NY, which will work on multiple diesel engine platforms, but the Duramax remains king.

“The Duramax is where my real interest lies,” he says. “I like to develop a lot of my own fabricated components for them. We look at what works best for airflow, what works best for fueling, what works best for all the different setups with them – camshafts, injection pumps, multiple pumps, etc.”

Richie’s Diesel Performance is located outside Manhattan in Western Long Island where there are a number of shops around, but Strube has a monopoly on the diesel performance work.

“I would say 90% of my clientele is here for performance reasons,” he says. “There are a lot of shops around here, but really no diesel performance shops, so maintenance is something that you can pretty much go anywhere for. I don’t turn the maintenance away, but we’re not really equipped to handle large volumes of maintenance. I handle 80% to 85% of the workload that goes on here and I enjoy it.”

Strube’s shop also doesn’t do much machine work in-house, instead its focus is on assembly and disassembly of the engines that come in. The machine work is sent out to a number of shops better equipped to handle it.

“We use companies that specialize in machine work like Freedom Racing, NGM Diesel, Wagler, SoCal Diesel – those guys are phenomenal at what they do and I put my trust in them,” Strube says. “As far as our shop goes, the way we differ is we specialize in a lot of unique fabricated components for these Duramax engines. I’ll do little things like fuel fittings, special block off components and other things that don’t exist elsewhere.”

With a background in engineering and years of diesel training under him, Strube makes sure he applies what he’s learned over the years to his engine work. One such example is on his 2005 GMC Sierra with a 6.6L LLY Duramax inside.

“This engine is on its third version of what it started off as,” he says. “This truck and engine have been somewhat of an addiction. The truck used to run high 13s around 12 years ago. That engine had a bag of parts from Industrial Injection and the LBZ CP3. I didn’t have EFI Live. I had a PPE tuner stacked with a PS Performance fuel chip. It was a mess, but it ran some good numbers.

“However, we were breaking trannys because the truck weighs 9,400 lbs. In the 1/8th mile it was running high 5s, but then the head gaskets blew. Once the head gaskets blew, it was engine build time. That’s where it got real serious and I tore it all apart.”

For version two of the LLY Duramax, Strube put in some bigger injectors, 85% CP3, stock heads, racing cast pistons, and he added some serious water injection.

“We ended up running a little too much water at an Englishtown event in New Jersey and I blew a hole in the side of the head,” he says. “It hydro locked the engine, popped an injector up and the flame went horizontally through the side of the head. It shot out the seal in the water pump – it was pretty nasty.”

Now, Rich is on version three of the LLY Duramax, but it’s his best version yet!

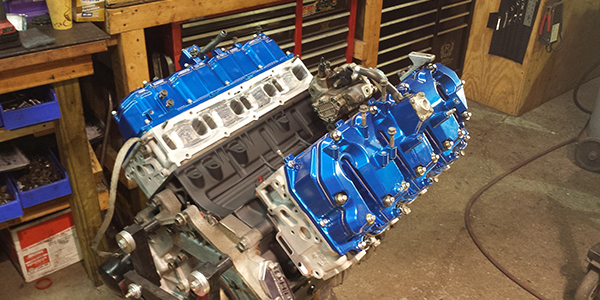

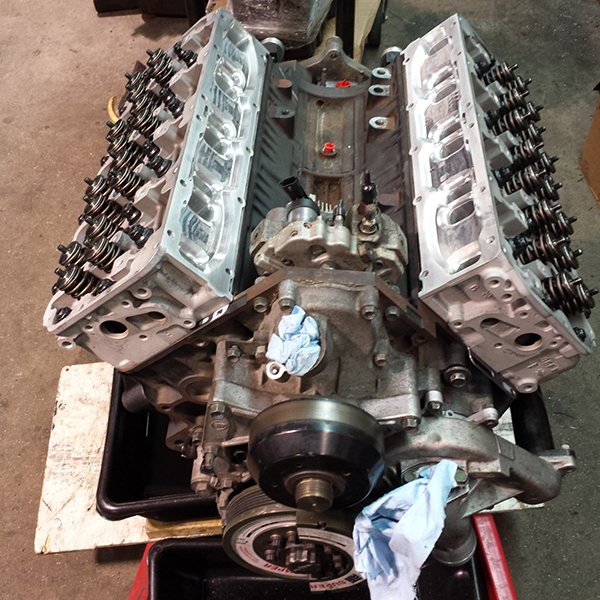

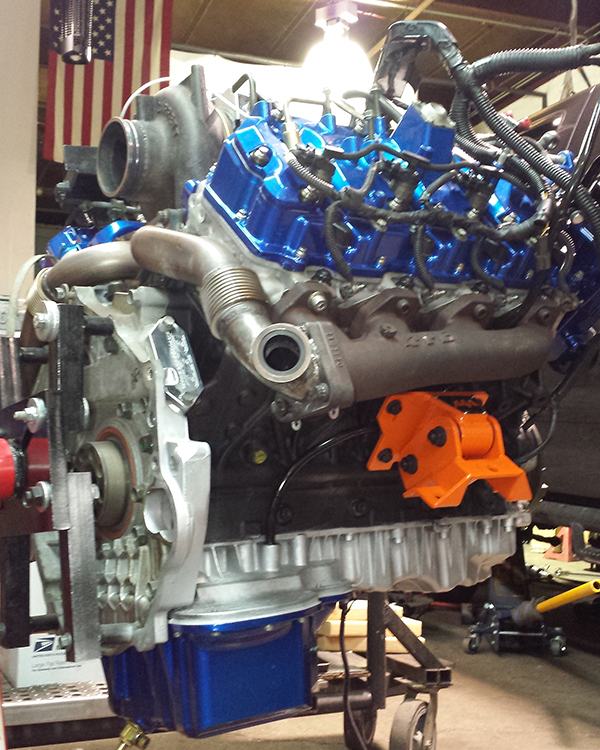

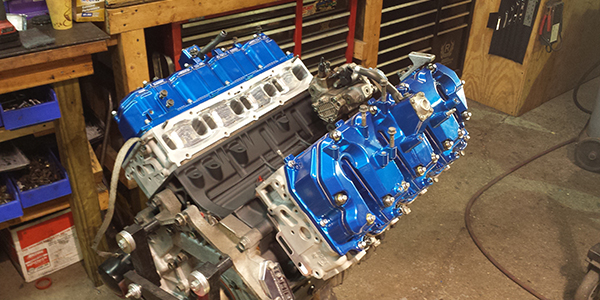

“It is still standard bore – 6.6L and 402.6 cid,” he says. “We didn’t oversize at all because there was no scoring to the cylinder walls or anything. Starting from the bottom, it’s got a forged crank that was prepped and balanced by Wade Moody at NGM Diesel. Wade did the majority of the machine work on this engine. I have Wagler Stage 2 heads on it. They are LLY factory heads, but they were finessed by Wagler to a Stage 2 design, which is heavy porting. The bowls are all blended, smoothed and rounded, the size is increased, they dropped the plenum, and overall they dropped a lot of material to get a lot of flow.

“It has an Industrial 120% pump, which I believe is their 14mm. I used to have a 16mm Frankenstein pump, which I was able to make just shy of 1,300 horsepower with. I turned it down a little bit because I was pushing the limit of this engine since it’s only built for a max of 1,500 crank horsepower. On the last dyno we made 1,485 horsepower at the crank and that’s as much as I want to push this thing because I don’t want it to explode.”

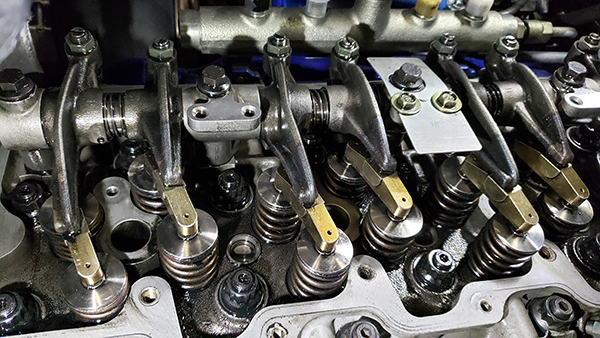

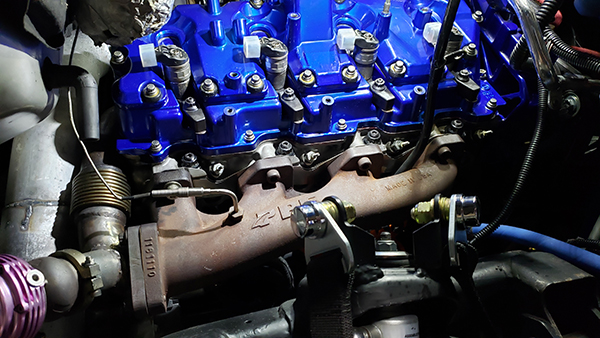

Other internals of the LLY Duramax include: Carrillo rods; 15.8:1 compression Mahle racing cast pistons; a secret squirrel camshaft from NGM Diesel; PPE manifolds and up pipes; a Danville 72mm, Stage 2 turbo, which is still a VGT; an HSP billet Y-bridge; factory Duramax rockers; Wade Moody’s double valve springs with titanium keepers, retainers and billet bridges; an ATI damper; an Industrial girdle; and ARP hardware.

“I took the PPE manifolds and up pipes and turned them into a wastegated design with two 38mm wastegates on them,” Strube says. “That’s what makes this thing stand really far apart from everything else. I’m still running the VGT charger, which creates so much drive pressure, so those wastegates allow it to breathe more, especially when it’s injecting the water and nitrous.

I have two stages of water and one stage of nitrous. It is a 3-50-400 shot of nitrous from Nitrous Express. The engine also has 150% Dynomite Diesel injectors and slightly oversized valves.”

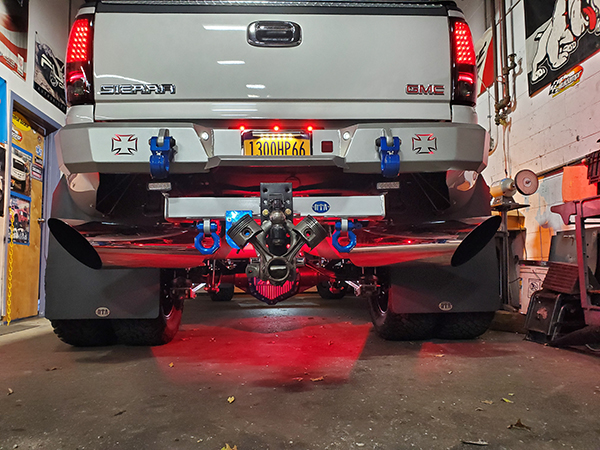

In its latest form, the 6.6L LLY Duramax is capable of putting down 1,277 horsepower at the wheels and 2,500 ft.-lbs. of torque! That’s thanks to the aid of AMSOIL running through its veins.

“I use AMSOIL 100%. I’m a firm believer in AMSOIL,” Strube says. “AMSOIL has supported us for over 20 years, and I have a full stock of AMSOIL here on a shelf that’s got to be 40-feet long.”

With the LLY’s latest combination, Rich does equal amounts of sled pulling and drag racing in his 2005 Sierra.

“We do just as much sled pulling as we do drag racing with the truck,” he says. “But being that the truck is so heavy, I’m not able to compete in the 3.0 class with it. I run it as an exhibition vehicle and just have fun with it. The fastest it’s run was an 11.9 @ 114 mph and a 7.68 at 106 mph in the 1/8th mile.”

Hopefully, a version four of the engine isn’t necessary, but if it is, we know it will be even better than version three!

Diesel of the Week is sponsored by AMSOIL.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].