Is growth part of your business strategy? It comes in a lot of different forms, but when it’s adding a new service offering or product for your customers, it can be nerve-racking at the very least. The additional investment in tools, equipment, training or people weighed against the unknown outcome leaves you holding all the risk, unless there is something that’s a perfect fit.

Take rear axle work, for example. Oddly enough, a lot of mainstream repair shops shy away from it, as if it’s a forgotten art. Of course, that really doesn’t come as much of a surprise when you consider all of the things we used to rebuild such as starters, alternators and master cylinders; things that in comparison are quite simple, but have gone by the wayside.

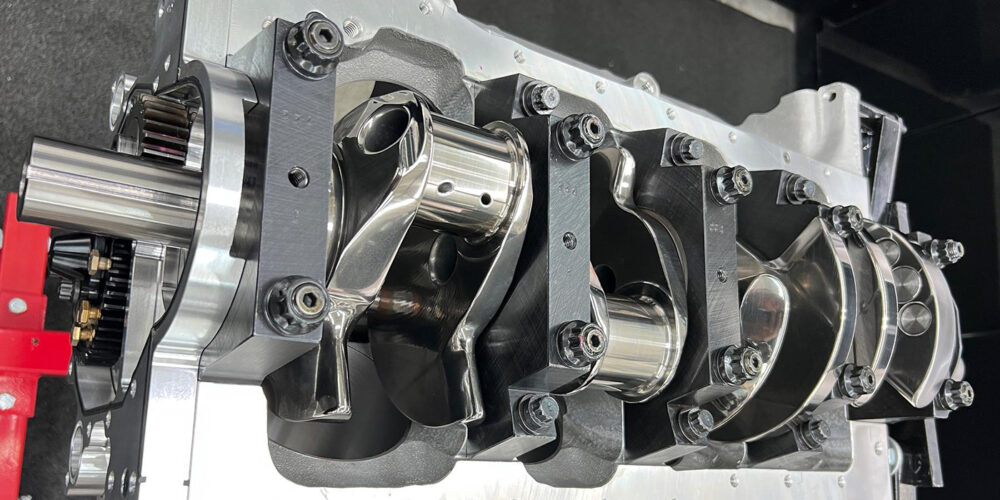

Rear axles require accuracy and precision, but as an engine builder, it’s what you do and most likely, your customer base is already there. You’re building an engine, and what’s it for? An old classic, muscle car or truck, maybe a Jeep? Regardless, there’s a good chance they’re already thinking about going through the rear axle at some point.

They may want to rebuild it as part of a restoration or change the gear ratio, and quite often the one-wheel-peel that their project came with just won’t do, so a limited slip installation is in order. Regardless, the vehicle is already down, what better time to have the rear axle done? You’ve almost certainly already had a customer ask you for a recommendation of who can do that, and there’s potential in saying “bring it in, we can do that for you.”

From the standpoint of tools, there’s not too much you need that you won’t already have. Most of the work only requires basic hand tools and standard measuring tools. You’ll need a shop press, plus you’ll need an axle bearing puller, just the simple slide-hammer type, for wheel bearings that are pressed into the axle tubes. A differential side bearing puller is needed, and a dial torque wrench, as well as bearing race and seal drivers.

A pinion yoke holding fixture is a useful tool to have, but it’s simply a piece that bolts onto the yoke and gives you leverage when loosening or tightening the pinion nut. I’ve seen many of these fabricated over the years.

When it comes to setting pinion depth, new pinion gears are marked with their proper depth setting. A high-quality pinion depth tool is expensive, but will save you time, and if you’re doing a lot of these, it’s worth the investment. Actual measurement is done with a dial indicator, but it’s the jig that makes the difference in quality and accuracy.

Pinion depth is a critical measurement, but regardless of how you get there, the bottom line is that once you’ve got things together, the reading you get from the marking compound on the teeth of the ring gear tells the whole truth, and you’ll want to make adjustments to pinion depth and backlash until the reading reflects proper setup.

A dial indicator is also used for checking ring gear backlash, the types of measurements an engine builder does in their sleep.

One final tool is a case spreader. All rear differential side bearings have a pre-load placed on them, some of which are done by tightening a threaded adjuster-cup, others by adding shims. For the shim-style, the easiest and most accurate way is to use a case spreader, allowing you to insert the final shims to create pre-load.

To set up a nice work area, a basic fixture can be easily built onto the end of a workbench, putting a rear-end at a good working height for draining, cleaning and assembly.

Disassembly goes quick. Remove the brakes, axles, differential carrier with ring gear, pinion yoke and pinion gear. The final step is to pull the axle bearings and remove any bearing races and you’re ready for cleaning. The order and specific steps vary depending on the rear-end you’re working with, but just like an engine, it’s ultimately all the same in the long run.

It’s a good idea to keep everything in order during disassembly. Bearing caps should go back in the same locations and positions, and while you can figure out the rest if need be, knowing the original position of the shims will make assembly go a little quicker.

Once you have everything cleaned up, this is also the perfect time to send out the housing to get media blasted and painted, or do it yourself, if your customer wants to go that route, such as this 12-bolt GM housing.

Getting the right parts is easy. You may have to look for particular features to identify the rear-end you’re working on, but once you know what you have, you can get a complete rebuild kit as well as a limited slip carrier, and ring and pinion that can be to your shop within a couple days, if not sooner.

Complete rebuild kits, such as the one shown here, contain wheel bearings, pinion bearings, carrier bearings, all seals, ring gear bolts and Loctite, pinion and backlash/pre-load shims, cover gasket and sealant, a new pinion gear crush sleeve and nut and marking compound for the ring gear.

The critical processes and settings during reassembly are pinion depth, pinion bearing pre-load, backlash and carrier bearing pre-load.

Pinion Depth

Pinion depth and backlash is what affects how long the gears will last and if they will run quiet down the road. Pinion depth, although it can be measured, and in theory set correctly the first time, may require adjustment after the initial setup, depending on the reading you get in the marking compound. You should only trust the pattern left by the gear marking compound as the final indication for proper setup.

Pinion Bearing Pre-Load

Proper pinion bearing pre-load is achieved by tightening the pinion nut until the specified rotating torque is met. Pre-load should be correctly set during initial installation for checking the pinion depth. After proper pinion depth is confirmed, install the new crush sleeve, pinion seal and pinion nut and set pre-load for the final time.

Ring Gear Backlash and Carrier Bearing Pre-load

Ring gear backlash should be set correctly each time prior to reading the pattern of the gear marking compound. Once pinion depth and backlash are correct, you can make your final bearing pre-load adjustments.

Rebuilding a rear end is just as rewarding as engine building, especially knowing that it is done right. When your customers already trust you for their engine work, it’ll be an easy decision for them to give you this additional work. Keep an eye on Engine Builder in the upcoming months. We’ll bring you step-by-step photos and additional information on this 12-bolt GM as we put it together.