Diesel of the Week is presented by

If you’re unfamiliar with Fleece Performance and its sister shop, Freedom Racing Engines, you might be living under a rock! In the past five years, Fleece Performance and Freedom Racing Engines in Brownsburg, IN have dominated the performance diesel space, and they have no plans to slow down the pace.

Owned by brothers Chase and Brayden Fleece, the emphasis for the two shops in 2019 was to put Fleece and Freedom under the same roof – a brand new 60,000 sq.-ft. facility – completed in September.

“Both companies are under one roof now,” says Chase Fleece. “There’s four engine dyno cells, three new build rooms, added machining capability – it’s pretty neat. The building is 60,000 square feet and Freedom’s going from 6,000 square feet to 10,000 square feet. It doesn’t sound like a huge jump, but the way it’s organized now, there’s going to be a lot more footprint to be able to actually manufacture what we’re trying to do.”

What they’ve been trying to do started all the way back in 2004, when Brayden and Chase graduated high school.

“We got into the diesel industry right out of high school in 2004,” Fleece says. “From then until 2008, we were just working on our own vehicles, which I had a 2002 Dodge Ram with a Cummins engine in it. My brother Brayden had a 2004 or 2005 Chevy Duramax. It was something we worked on and started playing with. We wanted to make more and more power and eventually you reach a point where you’ve got to beef up the engine.

“At the time, we were using some local machine shops and getting some stuff done, but we weren’t getting what we needed from our machine shops. Freedom Racing Engines was something we ran into in 2012, when we moved our business to Brownsburg from North Salem. We found Freedom Racing Engines and started using them. Within a year, we became one of their largest customers.”

In fact, Fleece was such a large part of the Freedom Racing Engines business, the Fleece brothers started negotiations to buy the shop, which they did in 2014. Within two years, they doubled the business.

“We essentially doubled or have grown that business by 100% every year,” Fleece says. “I don’t think we’ll be able to double its growth in 2020, but we’re sure as hell trying.”

Behind much of the growth at Freedom Racing Engines has been John Benshoof, Freedom’s operations manager. The Fleece brothers recruited John from a Top Fuel background.

“I’ve been here for five years,” says Benshoof. “I moved from Minnesota down to Indiana at the end of 2007 and worked on Antron Brown’s Top Fuel car from 2008 to 2012, traveling around the country, working on the pit crew. Then, for two years after that, I worked at Don Schumacher Racing in the machine shop, repairing cylinder heads and dabbling in CNC stuff. Everything kind of spawn from there.

“Brayden and Chase were looking for somebody. They had just bought this business (Freedom Racing Engines) in 2014 from an older guy in his 60s looking for a good exit. We got going and started growing and growing and growing and start working on the shop, started figuring out what we could do to pick up efficiency. We started adding equipment and things just started flying.”

While Fleece Performance is a full-service, dynamic diesel shop that also manufactures aftermarket parts, Freedom Racing Engines is not strictly diesel engine work.

“We do some gas engine builds too for drag racing, some truck pulling and we repair Top Fuel and Funny Car blocks,” Benshoof says. “As far as the business is segmented here, we probably do 80% diesel and 20% gas. If you rewound the clock five years ago, it would’ve been the other way with gas versus diesel. We’ve just built the business on diesel performance. We are geared towards common rail diesel engines from 2004 and up. That’s our forte. Our bread and butter is the Cummins stuff and second to that is Duramax. We don’t do a bunch of Powerstrokes. We build engines for everything from stock pickup truck builds to UCC, sled pulling, drag racing, hot street truck builds – pretty much anything across the board.”

Freedom has even developed its own remanufactured cylinder heads – the Freedom series cylinder head for the Cummins and the Duramax. In John’s time at Freedom, he has come to find there’s more similarities between diesel and Top Fuel than he thought.

“We’re making a ton of cylinder pressure on our diesels just like they are for the Top Fuel stuff,” he says. “When I transitioned into diesel, I started learning that the stigma of diesels being dirty, old, 12-valve, rolling coal – that’s not necessarily what we’re about. We make clean, crisp horsepower and do it the right way. Everything is basically electronic now on these things. And the technology that’s going into this industry is evolving so rapidly.”

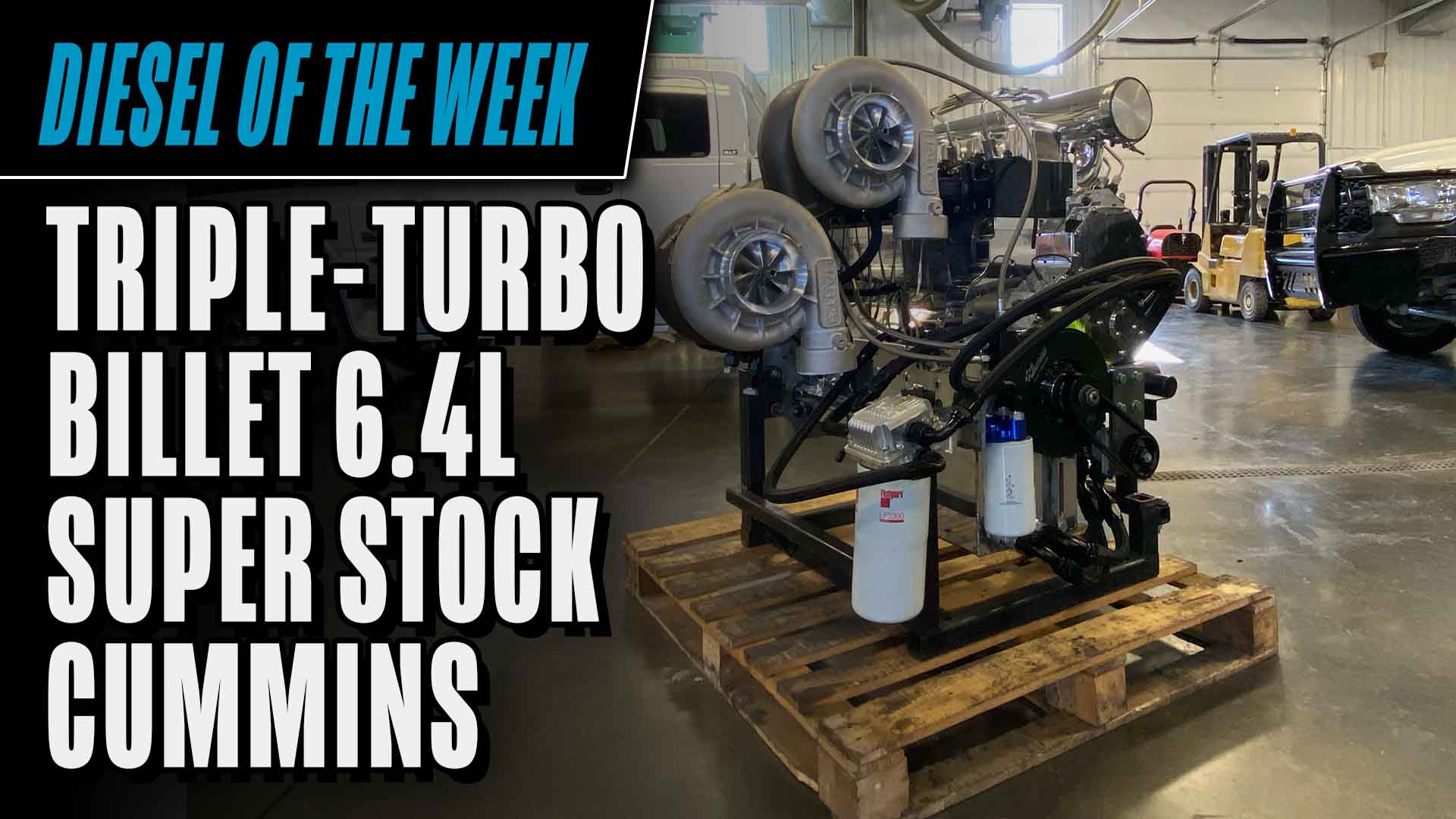

Evidence of that evolution can be seen in one of Freedom Racing Engines’ latest diesel builds of a 6.4L Cummins engine for a customer who wanted to have it all when it comes to performance.

“This customer is somebody we’ve worked with for a long time on various different projects,” he says. “The goal has always been to take his truck and make it the baddest, rowdiest street truck on the earth. It started off as 1,000-1,500 horsepower being the target, and it’s evolved and evolved and evolved.”

The customer’s name is Justin, and he is a farmer in North Dakota, as well as owner of JA Diesel Performance in Cleveland, ND. Justin wants to be able to drag race, sled pull and do dyno competitions, plus have the ability to drive his truck on the street.

“It’s one of these projects where he wants to make 2,000 horsepower, but also be able to drive it to Dairy Queen with his wife and kids,” Benshoof says. “This is the all-around, ‘I want to do everything type engine build,’ and it’s taken us a long time to get to where I feel we can develop that kind of engine and make it live.

“What we’ve run into over and over and over again was the block being an issue. In order to make the horsepower and cylinder pressure that is required, we have always had trouble with the engine block being the weakest link in the chain. It wasn’t until this year that Hamilton Cams came out with its 6.7L H-D wet block. With that block being a stronger piece, we are now able to work and develop around that block and have a foundation from which to build on.”

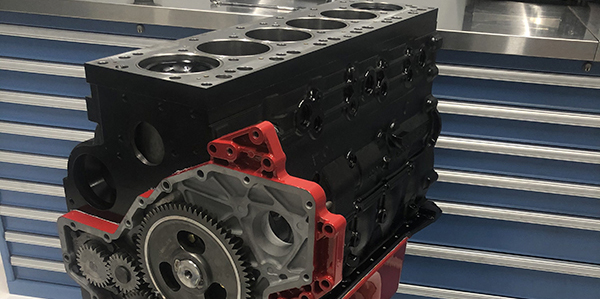

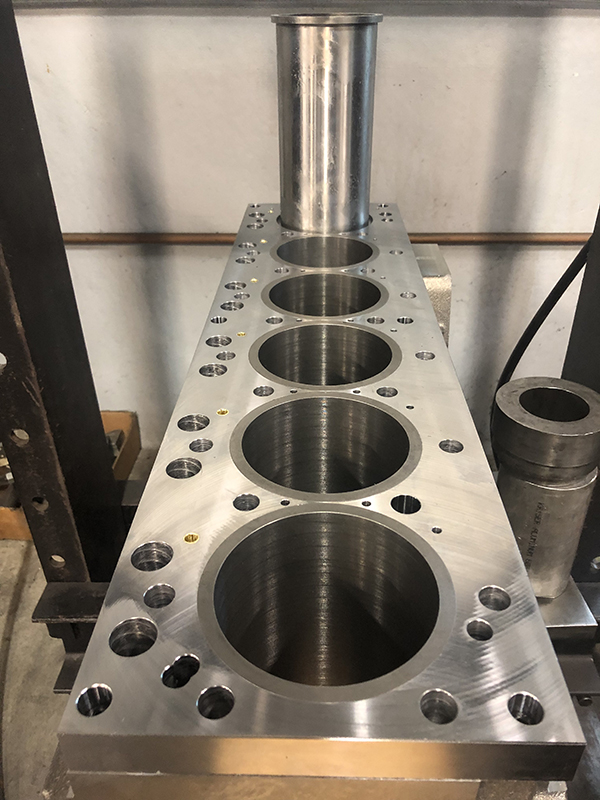

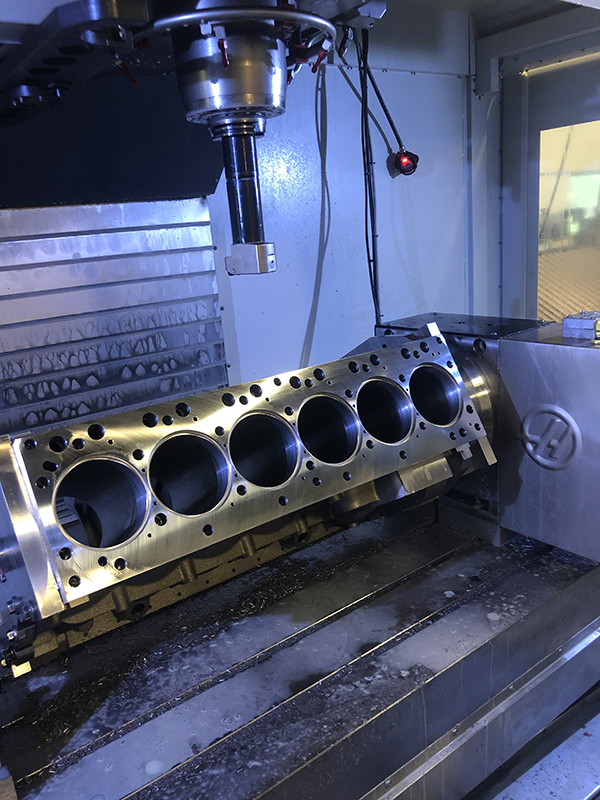

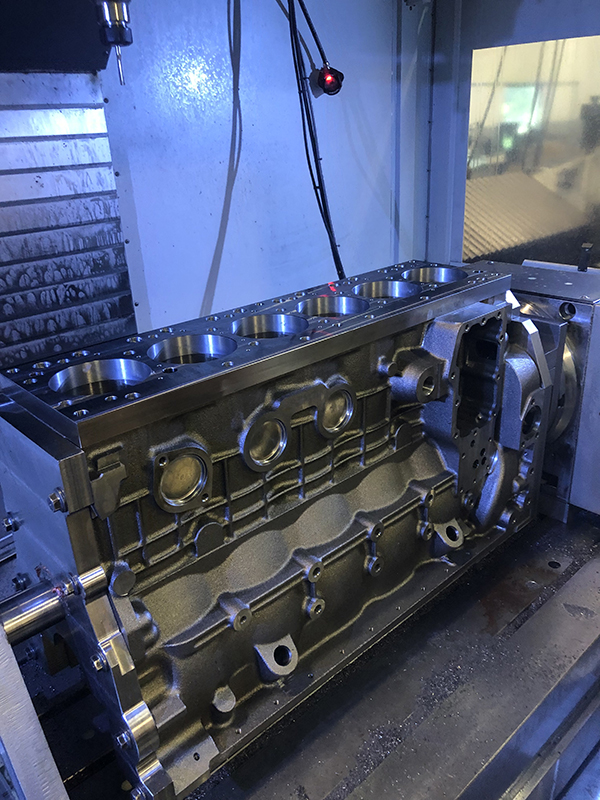

With the 6.7L H-D wet block in the shop, Freedom decided to step up the strength of the block by deck plating it and sleeving it.

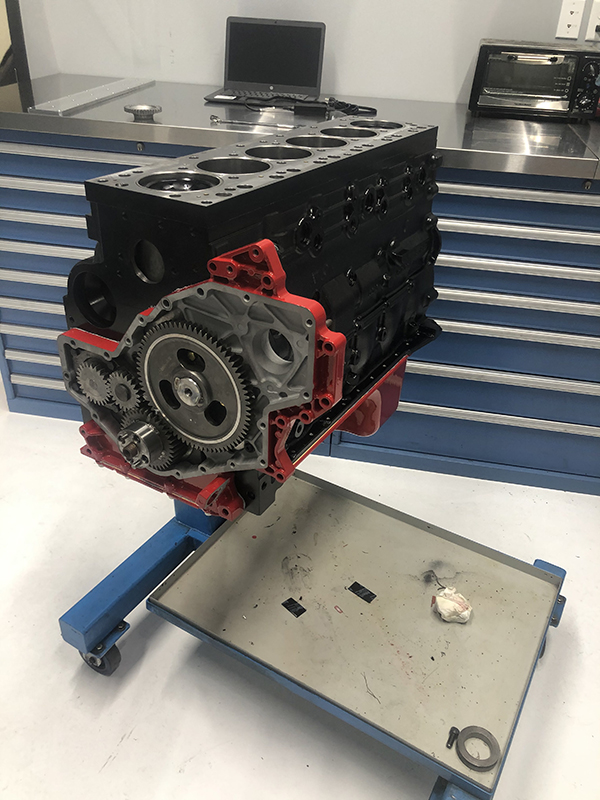

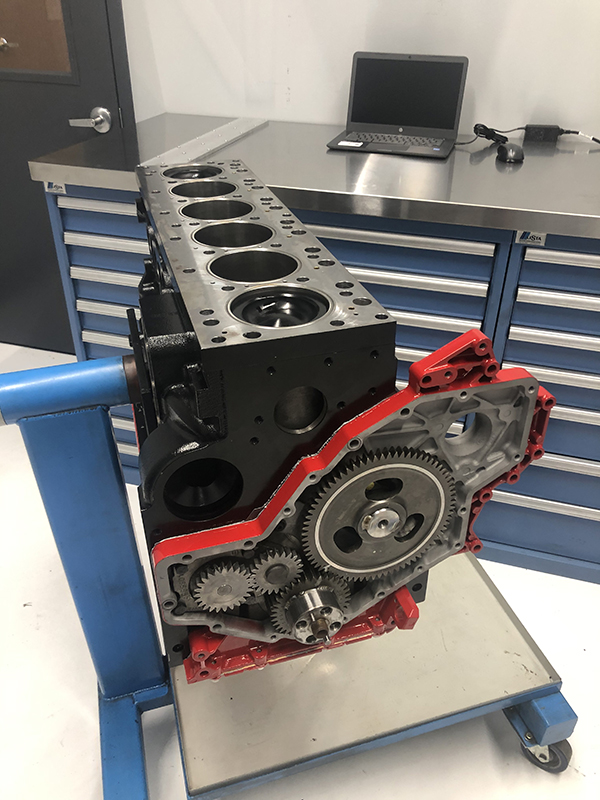

“We put our race girdle in the bottom end and went that route,” he says. “The engine is a 6.7L Cummins base, but we’ve gone down to a smaller bore. We shrunk it down a little bit to make everything fit into the package we wanted to run.

“As far as machine work goes, we got the block from Hamilton with 14mm main studs and head studs drilled in the block, but the bore is very raw. It starts off as a 3.8˝ bore, so we deck the block and bore it to the correct diameter for the sleeves that we press in (which makes it a 6.4L), and then we actually mill a receiver groove into the block and we embed our race girdle into the block, so it locates into the block as well as ties into the mains. We drill out the factory girdle because the factory uses M10 bolts, so we drill those out and put 7/16ths course-thread bolts in there.

“We haven’t really played with a wet deck plate set up before, so we had to basically develop our own wet deck plate kit. I hadn’t wanted to play in this arena other than with Justin because it’s kind of a unicorn – a 2,000 horsepower street truck that weighs almost 8,000 lbs. To run an 8-second 1/4-mile in that heavy of a truck takes a ton of horsepower. Those are some of the things that are the struggles through the build process.”

In addition, the Hamilton block doesn’t have all the coolant passages required, so Freedom had to add in a couple holes to match up to the gasket. Once the shop got that done, they were able to put the deck plate on, press in the sleeves and fire ring the block and head.

“We’re running a Carrillo 1˝-longer, H-D connecting rod bolted up to a factory Cummins 6.7L crankshaft,” Benshoof says. “We are running 4.125˝ Diamond forged pistons. We worked for a long time with Diamond Pistons and we have developed our own, proprietary piston design as far as the ring stack, the ring locations, the taper, the coatings, etc. We used Trend’s DLC-coated tappets and a flat-tappet billet Hamilton camshaft. We’re running Clevite bearings, Trend rocker bridges and Trend Stage 3 custom-length pushrods. We also used an ARP 625 deck plate 14mm head stud kit and an MLS fire ring head gasket kit. The cylinder head is a ported Freedom Racing Engines Cummins cylinder head with Freedom’s billet intake on it, and we run Manley stainless intake and Inconel exhaust valves.”

Once Justin gets the Cummins engine from Freedom, he will add an injector set up and a big compound turbo kit to help the engine achieve its 2,000 horsepower goals. Lastly, Freedom Racing Engines recommends using AMSOIL in a majority of its diesel builds.

“We use their 30-weight break-in primarily, and then we’ll jump over to the 15w50 diesel race oil,” Fleece says. “We also use 20w50 some, but that 15w50 diesel oil is our go-to. We’ve been real happy with it. The thing I really appreciate about AMSOIL is they’re extremely passionate about the whole motorsports industry. They take the time to listen to what our needs are, what our concerns are with an engine. When we pour that oil in the engine, that’s one thing I can’t worry about. The guys over at AMSOIL have been all-in from the get-go with us. They’re definitely on board and very helpful whenever we needed anything.”

Now that the 6.4L Cummins is in Justin’s hands, we’ll be anxious to hear how well those 2,000 horses perform across different applications!

Diesel of the Week is sponsored by AMSOIL.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].