Diesel of the Week is presented by

Travis Turner is the owner of Pure Addiction Diesel Performance in Hillsboro, OR, a diesel shop dedicated to general repair, maintenance and performance diesel work. As his diesel shop’s name suggests, Travis got addicted to diesel work after just his first taste of diesel power and performance. In 2008, he bought his first diesel truck, a 2004 LB7 Duramax, and as his shop’s tag line suggests – Feed Your Addiction – Travis wasted no time feeding his.

“Back in 2008… I was in the transmission industry and had been building transmissions for diesel trucks,” Turner says. “I bought my first diesel for towing my boat and trailers, etc. From there, I just started adding to it – custom tuning, a rebuilt transmission, a lift pump, and other bolt-on modifications. I loved the power diesels made and I was addicted from that point.”

Travis quickly discovered there wasn’t anyone in his area working on diesels, or anyone who really knew much about them, so he set out to change that.

“I started working on my truck and then friends who bought diesel trucks brought them to me for tuning and bolt on parts,” he says. “Then it became friends of friends who were coming to see me. I was figuring out the ins and outs of transmissions to handle the additional horsepower and what parts worked and what didn’t work.

“The demand became more and more and more to the point where I actually rented a small shop and was working on people’s trucks. I had enough work that I decided to hire an employee and start Pure Addiction Diesel Performance in 2013.”

For about two years after that, Travis was still working a separate full-time job in addition to working at Pure Addiction. He would work evenings and weekends at Pure Addiction and work his full-time job in between.

“In 2015, I went full-time with Pure Addiction Diesel,” he says. “That’s also the year when we moved into our current location – a 10,000 sq.-ft. shop with 1,500 additional sq.-ft. for a dyno room and storage.”

Today, Pure Addiction Diesel Performance has 12 employees and does anything from suspension, engines and transmissions for daily driving vehicles to performance vehicles with a focus on Ford, Chevy and Dodge.

“I have technicians for each platform who specialize in each platform,” Turner says. “We have nine lifts and 11 bays in the shop. We get through quite a few trucks.”

One of those trucks is Travis’ own race truck, a 2016 GMC with a 6.6L LML Duramax under the hood. Travis bought the truck in bone stock form, but it certainly didn’t stay that way for long!

“It’s one that we built from the ground up,” he says. “On the 2016 LML, we’ve built the transmission, the engine, turbo set up – everything.”

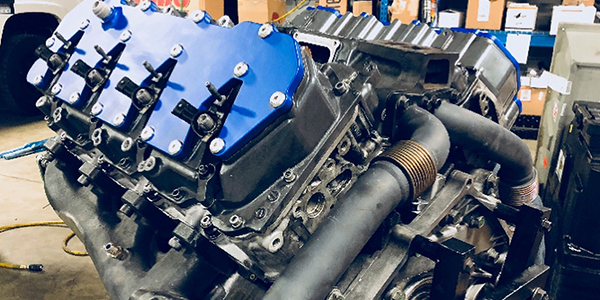

The build started with the stock block LML. From there, Pure Addiction added a set of Carrillo rods, Fingers oval bowl pistons, a Callies Durastar crankshaft, ported cylinder heads, a set of performance valve springs and pushrods, a SoCal alternate fire camshaft, ARP 625 head studs and main studs, an Industrial Injection billet girdle, an ATI damper, Steed Speed manifolds, PPE pipes, an ATS billet flex plate, 369 and 488 BorgWarner SXE turbochargers, and a Screamin’ Diesel Performance compound kit, piping and billet Y bridge.

“The first, initial engine, we used a stock crank and we broke the crankshaft, so we had to go back through the engine and installed the Callies crank, which initially when we built the engine wasn’t on the market,” Turner says. “Luckily, a year later, we got that taken care of.

“Also, initially we had a stock VGT charger in the valley with an S480. Then we went with a 369 in the valley with an S480. Then we swapped the S480 out for an S488 because we were always trying to break that 1,000 horsepower mark and we were always between 850 hp and 950 hp on those other setups.”

In addition to the components already mentioned, the 6.6L LML got an AirDog lift pump, a single Exergy 12mm pump, 100% over Exergy injectors, and a set of solid engine mounts.

“We kept breaking the stock mounts,” Turner says. “The motor kept twisting over and the S488 kept slapping the coolant tank. We had to find someone that made some solid mounts for that thing. As far as the trans, we built the transmission in-house. It’s got GPZ frictions, billet planet, billet input shaft, a Goerend converter, a BD double stack trans cooler, and a Mishimoto intercooler.”

Any machine work on the LML was done by Pure Addiction’s local machine shop. And while this LML Duramax started life as a daily driver used for towing, as improvements were made and the horsepower numbers kept climbing, Travis entered the truck in several performance and racing events.

“We competed in the Gauntlet Challenge at ATS,” he says. “We have drag raced it, dynoed it and we even dirt drag raced it at Alligator’s Hunting for Horsepower.”

To get the LML Duramax over the 1,000 hp mark, Travis and his team at Pure Addiction Diesel also had to fight some drive pressure issues.

“We had multiple sets of manifolds and up pipes and we were fighting drive pressure issues,” he says. “We had three different sets on there. We dropped almost 35 lbs. of drive pressure switching from AFE headers to the Steed Speed manifolds. We dropped almost 42 lbs. over stock. That was a challenge we had trying to get drive pressure down.

“We also have a nitrous kit from Nitrous Outlet with a progressive controller. The engine also has SoCal’s billet valve covers and some billet injector hold downs since we kept blowing out injector o-rings and copper.”

With the 6.6L LML Duramax all dialed in, the engine has gone from bone stock to cranking out 1,200 horsepower!

Diesel of the Week is sponsored by AMSOIL.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].