Are you out there making waves?

Competitors race in either v-bottom or catamaran-style powerboats, which can run in a number of different classes, often competing in individual races, on the same course, at the same time. Racers and pleasure boaters alike can compete in offshore series’ classes and shootout events across the country. Depending on the class, boat and engine(s), speeds vary from 85 mph to 200 mph out on the open water.

While offshore racing has widely been known as a ‘rich man’s’ sport, today, more people than ever are getting involved, making the offshore engine market one of great opportunity for engine builders.

Series and Classes

Globally, the premier racing series is Super Boat International, but other racing series here in the USA include the Offshore Super Series, the Offshore Powerboat Association (OPA), the American Power Boat Association (APBA) and Powerboat P1.

Super Boat International (SBI) is the longest running professional offshore racing organization in North America. The SBI season runs April through November and the final race of the year is the famed Key West World Championships. National races take place in Miami; Sarasota, FL; Michigan City, IN; Cocoa Beach, FL; New York, NY; and the National Series Championship event is in Clearwater Beach, FL.

The Offshore Super Series Powerboat Racing Association (OSS) was founded in 2003 by an elite group of race team owners and professionals to form a unique organization focused on fairness and safety. OSS offshore events are hailed and admired by all involved.

Originally a regional sanctioning body with a focus on the Northeast, the Offshore Powerboat Association (OPA) recently partnered with the American Power Boat Association (APBA) to sanction offshore races, and teamed with Powerboat P1. Through this partnership, OPA and Powerboat P1 created the APBA Offshore Championship Series, a six-race schedule with three events in Florida and one each in Lake Ozark, MO; St. Clair, MI; and Michigan City, IN. A separate world championship is held in Englewood, FL in November.

The boat debuted in the 2007 season and has competed in events across many race sanctioning organizations. Team AMSOIL held the title as Super Cat Lite National and World Champions back-to-back-to-back, 2010-2012 and was also OPA High Points Champion in 2011. The boat features two 750 hp TCM engines.

In addition, Race World Offshore (RWO) was recently recognized as an APBA sanctioning body, and will be producing the World Championships in November in Key West, FL for the next five years. This racing series is one to keep your eye on.

Offshore racing typically requires a team of one driver and one throttleman, and racers can enter a number of different classes based on their boats and engines. Some of these more common classes include: Class One; Super Cat; Super Stock; V-Bottom; and bracket racing classes referred to as Class1-7, where racers can’t exceed their class speed limits.

“The way offshore racing is set up now is a lot of the classes are like bracket racing and drag racing, where they set up a speed limit and they put a GPS in the boat that tracks their location on the course and their speeds,” says Tyler Crockett, owner of Tyler Crockett Marine Engines in Ruby, MI. “They’ve got to run as close to that speed as they can and it comes down to acceleration. When you go into a corner, if you’re running the 85-mph class, it’s all about getting back close to that 85 mph again as quick as you can. You’ve got to set the boats up to handle and accelerate at the same time.”

Photo by Erick Bryner | Fast Loud Photography

Since the news of OPA, APBA and Powerboat P1 joining forces, many racers and pleasure boaters are running in the classes under that series.

“OPA and APBA are the two bigger series,” says Daryl Hameetman, owner of Hameetman Racing Engines (HRE) in Cape Coral, FL. “OPA had more races on the schedule than anybody this year.”

Making Waves

With the popularity of offshore racing hitting new highs and more classes and events allowing pleasure boaters to join in on the fun too, the opportunities within the offshore marine engine market are really good today. Don’t believe me? Just ask Bruce Baker and John Kaeserman of Express Engines Inc. in DeLand, FL.

“The marine market is better than a lot of the automotive racing circuits,” Kaeserman says. “Most of the guys who have a $500,000 boat can afford it. Most of the guys who have a racecar, can’t afford it. It’s that simple.”

Express Engines works with customers in the SBI circuit as well as Class One offshore racing, which has garnered the shop clients all over the world. Crockett, Hameetman and Alexi Sahagian, owner of Boostpower USA in Newbury Park, CA, have also bolstered their clientele with racers and pleasure boaters from all over.

“When you go to these offshore races, lately, there’s been roughly 60 boats,” Crockett says. “Over half of them are set up for the bracketed class. It gives everybody a chance who wants to race. If you show up with your pleasure boat, as long as you’ve got the right safety equipment, you can run your boat.”

The majority of Hameetman’s customer base run pleasure boats, as do Boostpower USA’s customers. The strict race boats are now the minority customer base.

“There’s way more numbers and volume of dollars in the pleasure boat market,” Sahagian says. “We produce engines from 700 to 1,500 horsepower on a daily basis for offshore boats and pleasure boats.”

No matter if you’re in a pleasure boat or racing in an elite series, the engine or engines behind you, can make or break your race. As the classic saying goes, “You can’t win the race if you don’t finish,” so engine setup is critically important.

Offshore Engine Setup

Offshore marine engines are not very easy to build, so it takes a skilled and experienced engine builder to churn out the power levels most customers desire.

“A lot of non-marine engine builders build great engines, but they can’t figure out how to get them to live in the boats because of all the things that go with it,” Sahagian says. “Boats are just different, and they’re under load 100% of the time, so the engines are built looser than an automotive engine. Your bearing clearances are much bigger. Ring gaps are bigger. Piston to cylinder wall clearances are bigger, etc. If you put an automotive engine in a boat, it won’t last an hour.”

In offshore powerboat racing, most boats fall under either a catamaran or a v-bottom, and typically these boats feature twin engines or a single engine. In some cases, these boats can have three or even four engines, but that setup is far more rare.

In the Super Vee Lite class, the majority of boats are in the 30-foot range. In the Super Cat class, they’re anywhere from 36-40 feet. The Super Cats run twin engines and the Super Vee Lites run a single engine.

“The hottest engine going right now is probably the big block Chevy 509 cubic inch motor, because they use it in the Super Vee Lite class,” Crockett says. “The Super Vee Lite class uses a single engine, you can’t exceed 9:1 compression, has a max lift of .630 and uses a hydraulic roller camshaft. In the Super Cat class, they run basically the same 509 cubic inch engine, but they allow those guys to go to 9.5:1 compression and they can use a solid roller camshaft with a .720 max lift. Those are the two main classes in offshore racing now.”

Today, most offshore marine engines are based on the big block Chevy platform, which has risen to the top for marine applications due to parts availability and the torque necessary for these boats to perform.

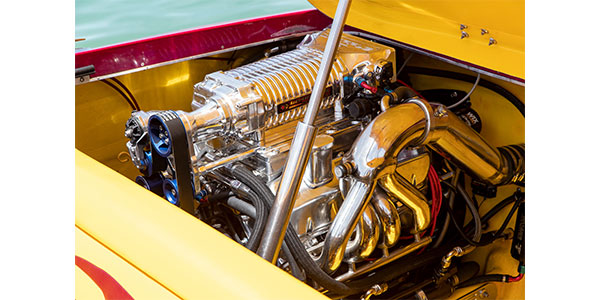

“It’s all big block Chevy related using a custom aftermarket billet block, Chevy firing order or LS firing order, 540 or bigger cubic inch and usually fuel injected and supercharged,” Sahagian says. “That’s the most common thing because torque is so critical. These boats don’t work unless they have 700-800 ft.-lbs. of torque or more for the most common builds.”

Hameetman agrees, saying, “Most of the engines we build for offshore applications are supercharged pump gas motors in the 850 to 1,250 horsepower range for the pleasure boats. Most all of them are big block Chevy based between 588 cid to 604 cid. The 588s have a little less stroke. We run those in the catamarans that like rpm a little bit more. The idea behind those engines goes back to the old-school thinking of the bigger the motor, the easier it is to make power.”

Superchargers are also on the rise to make sure these boats have the proper torque they need.

“For a boat to go from a zero dead stop to getting up on plane, that requires a tremendous amount of torque to put to the propeller to get the boat to crest over,” Sahagian says. “A supercharged engine with some good, low-end torque sure helps the boats get up on plane and drive what you would feel as normal. On some turbocharged applications, you’d have to use a gear splitter or a transmission to get it to feel normal because the turbos can’t spool at those low rpms in most cases.

Photo by TCM

“We tend to use supercharger technology and usually it’s more than one. We have our own twin Magnuson deal that we make castings for here in-house. We also use Whipple superchargers on smaller, single engine applications. We couple that with piston and cam design to get maximum torque right off idle. The torque can be as high as 900 ft.-lbs. at 2,500 rpm.”

With everyone running a similar engine platform, the difference maker comes down to the engine setup, the parts and how good your engine builder really is.

“The biggest thing as far as building these engines is you can’t cut any corners on the part selection,” Hameetman says. “You have to run the best parts available to have good results. You’ve got to overbuild everything for the environment. The power and abuse these motors take from moving a heavy boat and being on and off the throttle for hours on end are immense.”

HRE starts its offshore engine builds with iron blocks and aluminum cylinder heads and has increased the amount of parts coatings involved.

“We use Dart blocks pretty exclusively for the bottom end stuff,” he says. “Mostly Crower rotating components and then Dart or Brodix cylinder heads on the top. Most of the engines, up to 1,200 hp are wet sump. Anything beyond 1,150-1,200 hp we use a dry sump system. The dry sump moves a little more oil and helps with cooling the motor internally. But the wet sump pumps have gotten so good and it keeps the rigging cleaner, so most guys don’t want to deal with the extra accessories.

“We’re also starting to do more of the EFI stuff on these engines with some of the rear-entry Whipple superchargers. The cooling systems are also important, and you have to run more stainless fittings or bronze inserts on certain parts to try and keep the corrosion to a minimum to keep the engine in the field longer. We run coatings on cylinder heads and other parts to keep them alive longer. We also have to spend money on stainless hose ends because the aluminum stuff just doesn’t hold up if it’s in a saltwater environment.”

Tyler Crockett Marine Engines has resorted to similar setup techniques in order to keep customers boating and racing longer.

“Everything inside and outside of these engines has got to be able to take the shock of running and hitting waves,” Crockett says. “Everything has to be vibration proof and everything has to be secured. A lot of times, we’ll run double clamps on our distributors so they don’t move when they’re hitting the rough water, and we run brackets on just about every component to be able to take the shock of running in the rough water.

“We even went to real deep groove v-belts and pulleys because you’re on and off the throttle in the rough water, so that allows for less of a chance of a belt coming off and costing you the race. We also use double hose clamps on a lot of the main water hoses because you can build a lot of water pressure when you’re coming in and out of the water. Therefore, we’ve got blow off valves on our sea strainers because the pressure will spike over a couple hundred pounds.

“We generally start with a Dart block and we machine them to our specs for the marine racing. We also do a lot of coatings inside our engines and we put oilers in there too. We use piston oilers and we use an oiling system that bolts in the valley to spray oil on the lifters also. We do a lot of internal oiling in marine engines.

“We also make sure we get large volumes of water through the engine to keep it cool. The lake or ocean acts as the radiator for our engines. We improve the water flow by using a two-stage water pump on our engines – feeding one side of the motor with one stage of the pump and the other side of the motor with the second stage of the pump – so we’re running larger volumes of water through the engine.

“We also set our clearances up a little looser for the longevity and durability of the marine engine. As far as the components, we use a steel rod with an EDM hole up the beam where we can actually pressure feed the wrist pins with oil. We do that for longevity reasons. Other than that, it’s pretty much all the same components you would find in a drag racing engine.”

When these big block Chevys are in optimal running condition, the Super Vee Lite boats usually pump out 675-700 horsepower with their single engine, and the Super Cat boats crank out 800-825 horsepower out of each twin engine.

“The way the racing is set now, these boats are doing shorter courses, but more laps and more turns coming out of the corners,” Crockett says. “Because of that, you can lose a lot of ground on acceleration in two laps. That’s forced us to build these engines for acceleration, so we’ll use a lightweight crankshaft, aluminum flywheels and try to use lighter weight components so the motor will accelerate faster without giving up durability. It’s kind of like what they do in NASCAR.”

Due to the damage potential with these engines from things such as water ingestion, corrosion, parts coming loose or breaking, and countless other issues, staying on top of your engine maintenance is crucial.

Engine Issues

As the saying goes, “A boat is a hole in the water you throw money into,” but a lot of those maintenance woes can be alleviated by a boat owner who keeps up on maintenance and engine refreshes. In this regard, it’s no surprise that saltwater is one of the biggest culprits when it comes to causing engine damage in offshore powerboats.

“A lot of it comes down to the end user and how well they flush the engine(s) after every use,” Hameetman says. “Maintaining it is up to them and some guys are really good about it and have great luck with it, and other guys, not so much.”

“Saltwater is the biggest enemy,” Crockett agrees. “Saltwater corrosion will eat the aluminum heads and cause problems. We put the heads in the mill and I mill into the aluminum head until I get clean aluminum. Then I weld them all back up and resurface them.”

powerboat rigging too. Here, a catamaran boat gets an engine installed at

Hameetman Racing Engines.

When engines come in for a refresh, the most common work is valvetrain related or it has water damage. That’s usually what a marine engine will run into if a header breaks or a tailpipe cracks or valves start sticking and the engine starts pulling water back in.

When marine customers come in to Express Engines, Bruce and John aim to deliver reliability over power.

“We want customers to have no trouble,” Kaeserman says. “We want them boating week after week. You can’t win if you’re not there, and you can’t win on the first lap either.”

Because engine durability is heavily weighted on valvetrain performance, that area of the engine must be in good working order. Tyler Crockett Marine Engines will typically change out lifters and valve springs on its pleasure boat engines about every 250 hours. For race team customers, the shop changes lifters and valve springs out every six races.

Since each boat owner uses their boat with different regularity, these maintenance upkeeps will differ, but it is still crucial to know when your engine will need a refresh.

“Some guys race every weekend and then obviously they’ve got to stay on top of their maintenance more often and rebuild sooner than the guy who races once a month,” Hameetman says. “For 1,000 hp, it might need a rebuild in 250-300 hours. The big horsepower stuff might be 60 hours, depending on how they run it.”

Baker adds that with powerboats there are far more factors than just the engine to consider. If you don’t have it completely dialed in you could put on 200 hp more and not go any faster.

“The bottom surface of the boat has to be right, the propeller, efficiency and drive height all play a factor too, and customers just don’t understand,” he says. “They just think I can get 150 more hp and go 5 mph faster. It doesn’t quite work that way.”

Speed is dependent upon a number of different factors, but a good working engine is certainly at the top of the list. With offshore powerboats becoming more popular and competitive than ever, maintenance and engine building will continue to be an important factor, making this market and these customers an engine builder’s best friend. Are you out there making waves?