Diesel of the Week is presented by

When Jeff Jarvis was first introduced to diesel engines at the age of 18, there was no turning back, he knew a career in engine work was the right move. Today, Jeff owns his own shop called Jarvis Kustoms in Stockton, CA, where he specializes in Powerstrokes and LS engine work.

“I started back when I was 18 years old,” Jarvis says. “I worked for a bunch of different companies, and finally, I went on my own about 10 years ago. March this year will be 10 years.”

While Jarvis Kustoms can work on a number of different jobs, 90 percent of the business is Ford work.

“I’m known for Fords here,” he says. “I specialize in 6.0L, 6.4L and 6.7L. I do a lot of LS motors here too. We also do a lot of fabrication work. I’ve got CNC tables, mills, lathes – I’ve got a lot of stuff. I try to do a range of not just one thing. We also work on Duramax and Cummins too, but I’m much more known for Ford.”

Jarvis Kustoms is run by Jeff and one other employee who manage two shops right next to each other in a total space of around 7,000-8,000 sq.-ft. Recently, Jeff had to complete engine work on his own Ford 6.0L Powerstroke engine after the water pump failed and his engine overheated.

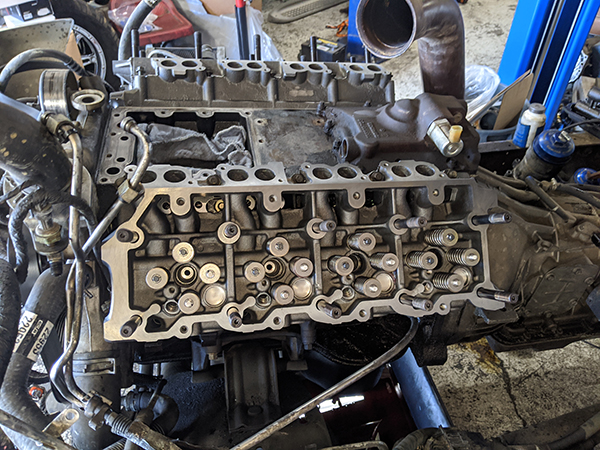

“I had to pull it apart and go through it and I ended up upgrading a bunch of stuff,” Jarvis says. “It’s a Ford 6.0L Powerstroke that’s in a 2004 F-250. When I pulled it apart, I noticed when the water pump went it cracked a head and blew a head gasket. We pulled the cab off and took it all apart. I took the whole motor out and I went through the whole motor to make sure it didn’t have cracked pistons, a cracked block or any of that.”

The 6.0L Powerstroke has a stock bottom end with the exception of an upgraded crankshaft. Due to the cracked cylinder head, Jeff went with new DK Engine Parts’ cylinder heads for the rebuild.

“I upgraded my heads to DK Engine heads,” he says. “I buy these heads a lot because the 6.0Ls are notorious for cracking heads. I always buy the heads from them and I’ve had good luck with them in the last six years I’ve been using them.

“I also used Sinister Diesel and Bullet Proof Diesel for parts such as ARP head studs, new gaskets, an upgraded Garrett turbo, Sinister Diesel EGR system, an oil cooler delete (to convert the engine from air cooled to oil cooled), an upgraded Sinister Diesel air cleaner system, Sinsiter Diesel up pipes and water pump, and Standard injectors.”

The 6.0L Powerstroke goes in Jeff’s 2004 F-250, which is primarily his work truck, but it goes to the occasional pulling event as well. With the engine rebuilt and featuring several new upgrades, the 6.0L diesel now pumps out more than 550 horsepower.

“I’ve had to upgrade at least one transmission because of it,” Jarvis says. Hopefully, that’s all he needs to do… for now!

Diesel of the Week is sponsored by AMSOIL.

If you have an engine you would like to highlight in this series, please email Engine Builder magazine’s Editor, Greg Jones at [email protected].