CORE PLUG PULLING

Some core plugs are notoriously tricky to remove. One example that I see a lot of is the deep plugs used in the back two positions of big block Chryslers where the cylinder wall is close to the plug hole. I simply tack weld a nut to the core plug. Then I can use a slide hammer to pull them out.

Joe DeGraw, Grawmondbecks Engine Rebuilding – Mason City, IA

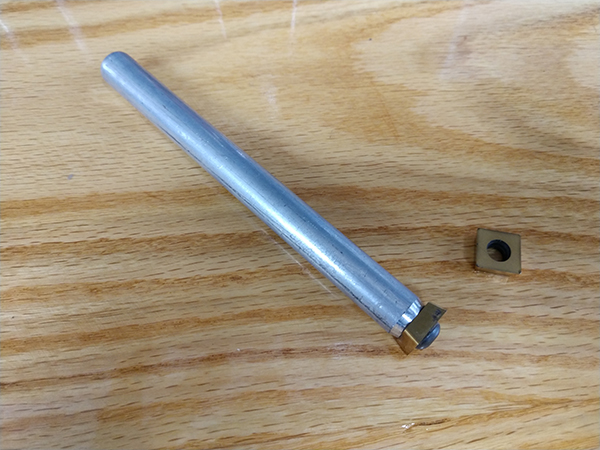

SIMPLE SCRAPER

I made a few of these simple scrapers to leave around the shop. They’re really great for getting after rusty surfaces. The scraper is an aluminum handle with used carbide tooling bolted on. They are simple to make. Repurpose your bits!

Randy Torvinen, Torvinen’s Machine Shop – Menahga, MN

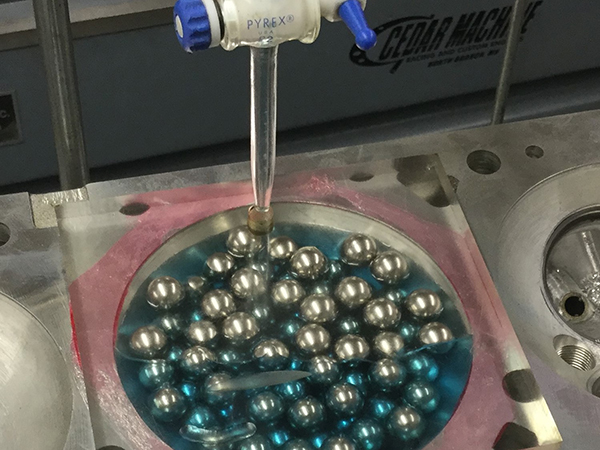

WASHER FLUID

When checking volume on cylinder heads, I like to use windshield washer fluid as the measuring liquid. To keep it from flash rusting seats and iron heads after it’s drained, I’ll put a splash of radiator coolant additive in the gallon jug. This has corrosion inhibitors that will stop the rust. Water Wetter works great for this. I also use it in any water-based cutting fluid for many other operations as well. Another great use is to add it to your bubble spray for pressure testing blocks and heads.

Ron Flood, Cedar Machine – North Branch, MN

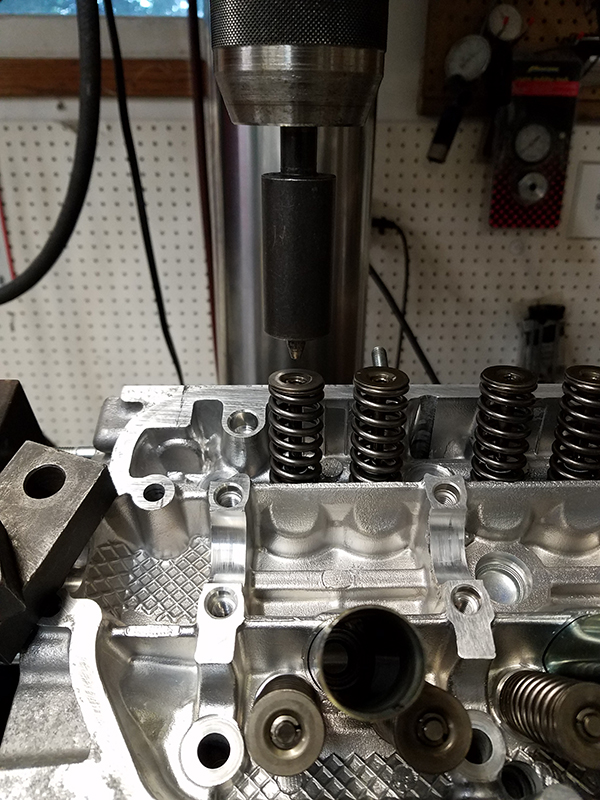

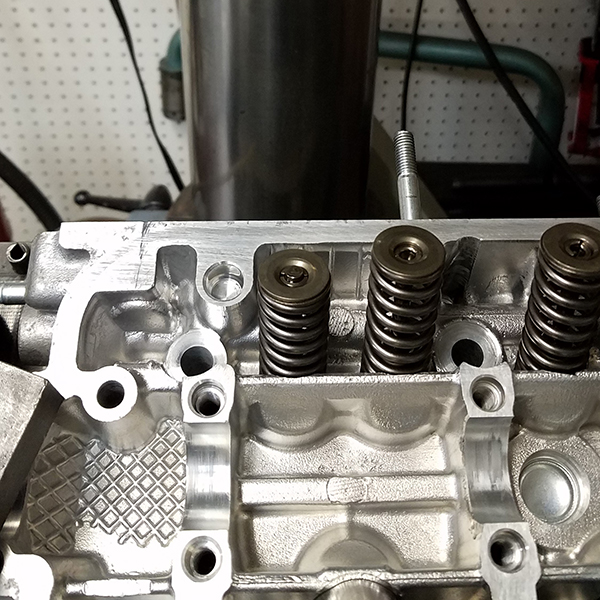

WORKING SMARTER

We have used a Lisle hand held keeper installer tool to assemble small import heads for many years. It can be hard on your hand pushing on the tool to get the keepers to seat, especially on aftermarket springs that are stiffer than the originals. It is much faster than using a spring compressor. It occurred to me that the tool would work just as well mounted in the seat and guide machine and it’s much easier on your hands! Pre-load in all your springs, retainers and keepers, then go right down the line and pop them together. This head went together in minutes.

Jake Sampson, Sampson Racing Engines – Inver Grove Heights, MN

RECYCLE YOUR RESOURCES

Most piston sets come in a bag. Some customers do not take off all the external parts when they bring in cylinder heads. Use those piston bags to put the various cylinder head parts in to keep them organized for reassembly. Place a label on those bags and put them in a box for safe keeping. This will save cost and will save time looking for the extra or lost parts.

Anita Satterfield, Satterfield’s Machine Shop LLC

GOOD SEATS

When I grind valve seats and want a nice finish when I get done, I take a strip of abrasive cloth about 1/4-inch wide and 4-inches long. I place it between the seat and stone with the abrasive side facing the stone. I hold the cloth with one hand and then turn on the driver for just a second or two. It makes the stone a lot smoother and leaves the seats with a very nice finish.

Dale Beran, The Parts Bin – Ord, NE