MANDREL ORGANIZER

Recently, I was walking through the shop and looked at my rod bench and noticed how all my mandrels were just lying on the bench disorganized and presented a bad look to customers who walk through my shop. I decided to fix that by going down to the local lumber yard and buying corrugated roofing material and cut it to the length I needed for my bench. I used some small self tapping screws to hold them down. Now all my connecting rod mandrels are neat, organized and present well to my customers.

Kody Redman, Redman-s Performance – Oakhurst, CA

TAPED FOR PROTECTION

When working with a customer’s brand new cylinder heads, I cover the finish machined ends with painters tape to avoid scratches during any finish procedures and assembly. When someone pays big money for a set of heads, the last thing they want to see is scratches from it having been stood on end. The same goes with the other surfaces that I’m not working on.

Ron Flood, Cedar Machine – North Branch, MN

SUNNEN CRG-750 FIXTURE TUNE UP

I just used a set of LS main caps to shim the fixed surface plate (opposite the clamp) on our cap grinder. LS caps are normally cut very square to the sides, but first I verified these with a machinist’s square. I use dye chem on the bottoms and just barely touch off on a known square cap. If it’s not touching off square you can use thin shim stock behind the surface plate on either the top or the bottom. If the cap isn’t square, but your plate is, you can use shim stock to get it square, again using dye chem to check contact before grinding. Someday we’ll upgrade to the wide two-post clamp so I don’t have to shim. With the wide clamp you can just grind the sides square, then go back and grind the bottoms. The CRG-750 uses a center-post clamp that is in the way, so you can’t grind the sides square. It really doesn’t take much longer to shim them square with enough practice. We keep a set of feeler gauges next to the grinder just for that. If you change the angle of the bottom of the cap you’ll not only have a hard time getting the bore back to straight, but you’ll also beat the heck out of your rod or line hone stones and guide shoes.

Jake Sampson, Sampson Race Engines – Inver Grove Heights, MN

WHY DOES THE HVAC TECH CHARGE MORE THAN THE MACHINE SHOP

I had a short visit from our HVAC repairman a while back. It took him about two minutes to pop the access cover, grab a tester and proclaim that the flame sensor had shot-craps in our 10-year-old furnace. He’d been in my office for a total of five minutes when he said I owed him $90.00 for the service call. I could install the sensor myself (there is a dealer across town), or he had the part “on the truck” for $30 plus $30 installation. After a quick calculation, I figured the extra $60 was cheaper than the hour or two I’d waste acquiring the part and making the repair. I reluctantly approved the job. The tech was fast. He scored $150 for 20-minutes of work. As he packed-up his “tool” (one screwdriver) I got to thinking about his company investment and how that relates to the guys in our business. This small business owner drove an older company van stocked with a few hundred dollars in repair parts and the rest of his assets hung on his butt! When I compare the investment a machine shop owner makes in equipment and training and the ROI (return on investment) he receives versus the HVAC guy, I realize there is inequity in our pricing model. I’ve spoken to countless shop owners who feel undervalued for the work they do, but most are afraid to raise prices in fear of losing business to the competitor down the street. This tip is simple – charge what you are worth. You gotta’ earn enough profit to update machinery to work on late-model engines, AND pay for good help, AND afford health insurance, AND retire some day! Here’s an idea… raise your shop labor today. Right now! The worst thing that will happen is a regular customer may notice and complain – you always have the ability to discount your labor for a good customer. Don’t let the HVAC owner retire before you! Make sure you are profitable and if needed, raise prices today.

Steve Rich, Sterling Bearing Inc.

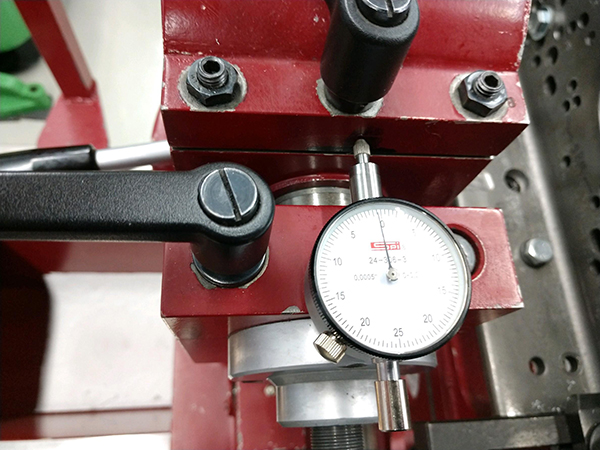

ANYWHERE INDICATOR

My line bore didn’t have any indicators on the column and it’s nice to know the amount you are moving the bar. I just siliconed magnets on the back of these small indicators for easy set-up. I use them on the line bore and other machines.

Randy Torvinen, Torvinen’s Machine Shop – Menahga MN