Another decade has passed and automotive technology continues to advance in what seems like leaps and bounds every year. Passenger cars currently come standard with options that were unheard of a mere 20 years ago. In motorsports, we see the constant engineering of critical components that result in an ever-evolving supply of parts that trump a competitor’s, or even a supplier’s, previous design. Parts like tires, shocks, engine blocks, cylinder heads, fuel injection, and believe it or not, carburetors.

I know what some are thinking. “Carburetors haven’t even been an option on production vehicles for almost 30 years. Why use old technology when there are so many fuel injection options available?” The truth is, the carburetor market has evolved right along with the ever-changing technology that surrounds it, driven by the need to stay relevant and remain a viable option for those looking to win races. Carburetor manufacturers and custom builders are thriving with more business than they have had in over a decade, or possibly ever.

It’s hard to believe, but the carburetor is one part of the vehicle, other than the wheel, that has seen the most time for development. The first carburetor was actually invented in 1826 by an American named Samuel Morey. It was implemented on early internal combustion engines that were fueled by turpentine. It wasn’t until 1872, when a German inventor by the name of Siegfried Marcus, first applied the carburetor design to a petroleum-fueled internal combustion engine. By 1886, the basis for this design would make it into the automotive market on what is recognized as the first automobile, the Benz Motorwagen.

With manufactures like Holley currently offering over 400 different part numbers and variations of carburetors, the carburetor market is far from dead. In fact, its in the spotlight more than ever.

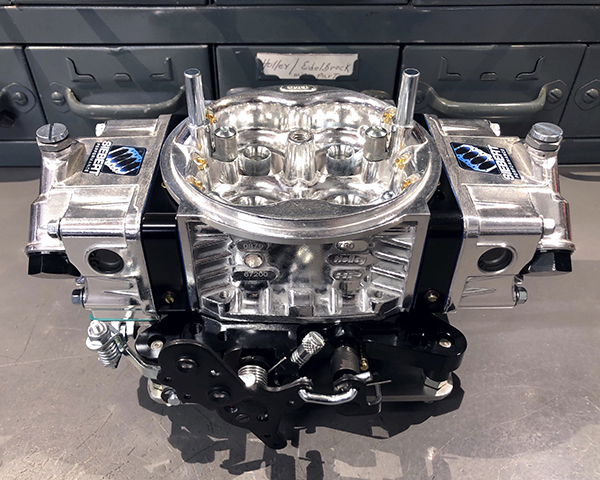

Fast forward to 1957, where Holley has already been designing carburetors for 53 years, the hot rod market is booming and Holley releases its first modular designed carburetor – the 4150/4160-style carburetor on the Ford Thunderbird. This design was a first of its kind because it allowed for easier tuning and unmatched performance when compared to anything else on the market. This is the beginning of carburetor performance as we know it today.

It doesn’t matter if you are into drag racing, circle track racing, or other forms of motorsports, chances are there are classes within the sanctioning body you follow that require carburetors. In those classes that don’t, it is still common to see a majority of racers still utilizing a carburetor or multiple carburetors.

In the NHRA, classes like Stock Eliminator, Super Stock and Competition Eliminator require the use of a carburetor in most combinations. In classes such as Super Street, Super Gas, Super Comp, and Top Sportsman, neither carburetion or electronic fuel injection is required, but at least 90 percent of those classes are dominated by carburetors. Whether it is a 4412 Holley 2-barrel or a custom billet 4150 4-barrel, circle track sanctioning bodies like IMCA, USRA, USMTS, and WISSOTA require the use of a carburetor in nearly all classes.

Lately, in the heads up drag racing community, there has been a lot of buzz surrounding a new class dedicated to the carbureted small block nitrous engine. Promoter Donald Long of Duck X Productions recently created the DXP (Duck X Productions) Street Class with rules requiring racers to run a 440 cubic inch or smaller engine that is a production-based small block platform with different weight breaks for 23-degree small block heads versus different 15- to 12-degree LS cylinder heads. Each engine can utilize a spec single 4150 plate nitrous system topped with a 4150 carburetor. The rules state “All cars are limited to a dedicated single 4150 opening cast intake and a single 4150 carburetor (4 blade, round 1.750 blade). The carburetor must have a commercially available cast main body and base plate. Billet metering blocks are permitted. Fuel injection of any kind is prohibited.” This should be an interesting class to keep track of when it debuts, which will be about the time this article hits.

The question remains, what makes carburetors so great? Why are they still so prevalent when EFI has been standard on production cars for 30 years? For many people, one reason is cost. The difference in cost between a carburetor and its supporting fuel system, and an EFI system varies depending on the horsepower that needs to be supported.

Hypothetically, let’s take a 700 hp, naturally aspirated engine as an example for a custom-built carburetor and fuel system versus a complete EFI system’s cost. The carbureted system will cost $1,600 on average, and the EFI system will cost $3,250 on average. That makes the carbureted system less than half the cost!

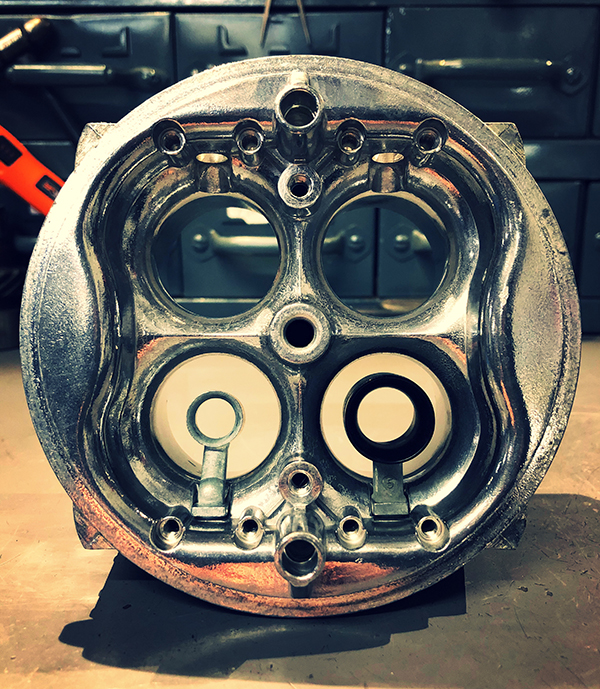

Secondly, carburetors make more power. I know, some of you don’t like hearing that, but the science backs it up. While EFI has the important advantage of cylinder distribution tuning, the systems are not designed to atomize fuel. By design, a carburetor’s primary job is to atomize the fuel before it even exits the booster. Emulsion bleeds in the metering blocks inject air into the liquid fuel that is in the main well causing it to turn into a light, homogenous mixture that can be more easily lifted to the booster. Once this mixture exits the booster it is blown apart by air that is being accelerated to a high velocity through the venturi of the booster and spread into a nice cone-shaped column of air/fuel fog that is perfect for the engine to consume and burn. A fuel injector does not have this advantage, as its only capability is to spray a high-pressure quantity of fuel across an orifice to turn it into droplets. These droplets must see copious amounts of swirl and tumble of the airflow to help them mix with the air.

A carburetor’s primary job is to atomize the fuel. the air/fuel mixture is being accelerated to a high velocity through the venturi of the booster and spread into a nice cone-shaped column of air/fuel fog that is perfect for the engine to consume and burn.

Have you ever misted yourself with water on a hot day to help cool yourself off? If so, you have experienced the effects of evaporative cooling! This cooling action happens when liquid particles that are rich with kinetic energy are forced to separate from the base liquid and turn into a gas. The exit of these high energy particles leaves the base liquid with less kinetic energy, therefore, less overall temperature. Long story short, this is exactly what happens as the fog of fuel, generated by your carburetor, enters the intake manifold. The evaporating column of fuel is rapidly reducing temperature and in turn reduces the temperature of the air in the intake tract to roughly 15 to 25 degrees below the ambient air temperature. This allows for a greater density of oxygen, which leads to the potential for more power.

Simplicity is the final reason carburetors are still so relevant. No electronics or wiring is needed. Just bolt it on, hook up the fuel lines and go. To make calibration changes, simple hand tools like a 5/16ths nut driver, flat blade screw driver, and a 5/8ths wrench are all you need to change jets, air bleeds and float level. It doesn’t get any easier than that!

Now, I’m not going to tell you that carburetors are all butterflies and rainbows. They are amazing pieces of equipment that are versatile, make amazing power and are dead simple to work with, but in my opinion, they have three key downfalls. The first of which is fuel economy.

With proper tuning you can get very good mileage with a carburetor, but it just isn’t going to match up to what you can get with a well-tuned EFI system. Next is a carburetor’s poor ability to feed an engine in a “blow through” turbo or centrifugal supercharger situation. Fuel injection allows you the ability to much more accurately respond to rapidly changing manifold pressures and balance air/fuel ratios from cylinder to cylinder. This is exceedingly important when you can often be on the edge of detonation with cylinder pressures high enough to cause some real damage.

The final downfall is the fact that a carburetor has many more moving parts, gaskets and seals than EFI. Keeping your fuel clean and not letting the carburetor sit for extended periods of time are of paramount importance to maintaining a carburetor that operates properly and doesn’t leak everywhere. Even with good maintenance, I still recommend rebuilding your carburetor every two to three years depending on frequency of usage.

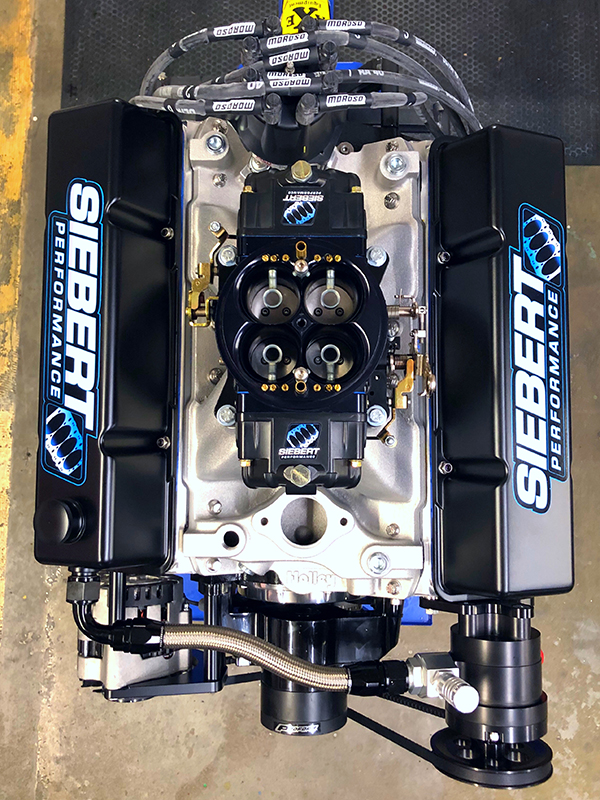

Are carburetors dead? With manufactures like Holley currently offering over 400 different part numbers and variations of carburetors, the carburetor market is far from dead. Aside from the large “production” companies like Holley and Quick Fuel, the performance carburetor market is also filled with custom carburetor builders such as Siebert Performance, BLP, Advanced Product Design, Sullens E85 Carburetors, Willy’s Carbs, and MANY more.

Custom builders are taking carburetor design and calibration to the next level by custom tailoring each carburetor they build to the end user’s setup. In the end, the customer is bolting on a carburetor that needs little to no tuning, makes more power, has better drivability, and provides a better overall experience than buying a generically tuned carburetor from a warehouse.

Think about it this way, would you buy a tune for an EFI system from a company that doesn’t ask what your camshaft duration is? How about your compression ratio? Or, most importantly, ask about the specific fuel you are running through the system? I would expect not, so why would we treat carburetor purchases differently? It is my belief that custom carburetor companies like these are currently bolstering the carburetor market and keeping this nearly 200-year-old invention a viable option for racers and other automotive enthusiasts as we head into the 2020s. EB