TIGHT TUBE BENDING

Sometimes you may attempt to make a short tight bend in a piece of steel or copper tubing, but your tube bender will not make as tight of a radius as you might desire. You know if you try to bend it by hand it will kink. If you run into this scenario, try this – melt soft solder into the tube to keep the tube walls from collapsing and you can make that bend without kinking the tube. After you have made the bend, heat the tube and simply blow the solder out. It works great.

Steve Albrecht, Goderich Machine Shop, Ontario, Canada

GEN V GM LT THRUST BEARING UPGRADE

The new Gen V GM direct injected V8s only come with a half thrust bearing in the main bearing set. The GM coated bearings are a very nice bearing if a bi-metal aluminum bearing is okay for the application. So far on the sets that I’ve checked, the sizing is amazingly consistent from shell to shell and from one set to another. The problem is on a high performance application making big power. This single thrust is not ideal, in my opinion. The good news is GM did cut the thrust face on the cap side, and the upper shell does fit in the cap. The GM part number for just the #3 upper is 12618105 which you can order individually from GM. There are no aftermarket coated bearings available at this time that I could find. You can use a Gen III or Gen IV LS main bearing set with minor modification. The alignment tang locations are different so you would need to grind new location grooves into the block and cap to get them to work, or just remove the tangs altogether. This is easily done with a file. The thrust bearing is the only one that is different.

Jake Sampson, Sampson Race Engines, Inver Grove Heights, MN

MORE FORD OIL RESTRICTION

On FE Fords it is common to restrict the oil flow to the rocker arms. To do this, simply drop a Holley main jet, of the restriction size you want, right into the oil feed hole under the rocker shaft. If you want to pull it out to change sizes, just poke it with a toothpick and pull it out.

Ron Flood, Cedar Machine, North Branch, MN

VALVE CLEANING

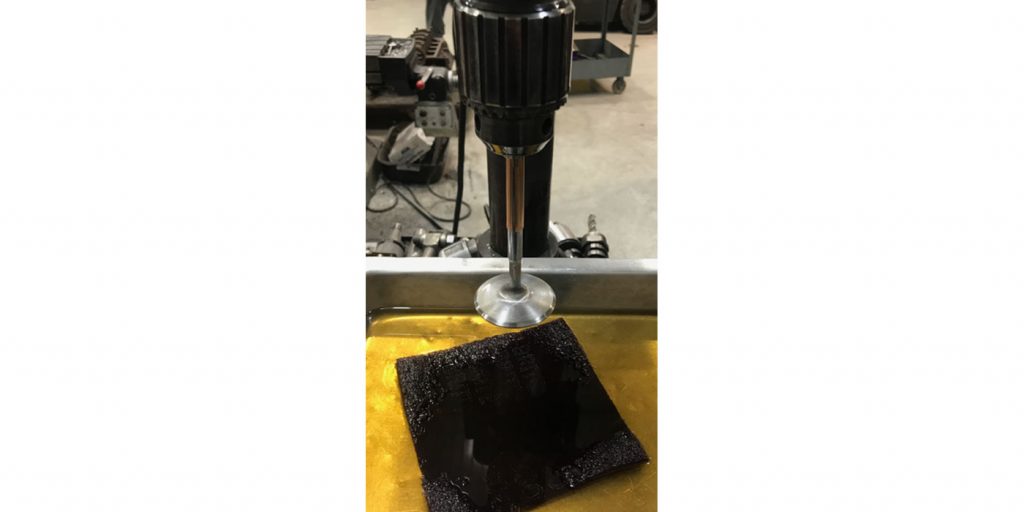

Take a valve guide liner (K-Liner or other) of the appropriate stem diameter and insert it into the drill press chuck. This will provide a nice protected grip on the valves while they’re spinning. Have a pan of solvent underneath and grip the head of the valve with a scotch bright pad. The valves will come clean and look like new.

Nick Jones, Automotive Machine, Fraser, MI

EASY HEIGHT TRANSFER

When setting up valve springs or checking valve spring pressure, I set a spring retainer on my height mic and use it to check the springs on the tester. To figure the installed height, bring the tester to the desired pressure and open the height mic to match and that’s your target installed height. In reverse, you can see where the spring pressure is on the heads now. It’s easy and quick.

Randy Torvinen, Torvinen’s Machine, Menahga, MN