Engine of the Week is presented by

People like Hunter Smith are bucking the trend that younger generations aren’t entering the engine building industry. In fact, Hunter is making it his livelihood. He started American Speed Shops a little over two years ago in Villa Rica, GA to focus on building top-of-the-line LS engines. With a background in bracket racing and an education from SAM Tech, he’s well on his way to doing great things in the industry.

“There aren’t many shops out here,” Smith says of Villa Rica, GA. “We’ve got a lot of dirt tracks, mom and pop passenger car shops, and then we’ve got Pro Line about an hour from us. There’s really no in between, so we went into it with the mindset of filling that void. Our goal is to be a household name or shop name like some of these other shops like Thompson Motorsports, Late Model Engines or Texas Speed.”

Hunter owns American Speed Shops along with his parents, and has one other employee named Chris Mackey helping him out.

“We definitely wanted to focus on making sure one person touches an engine throughout the entire process and making sure that our customers are not just numbers in a filing cabinet,” Smith says. “They’re actual racers and people who we know by name. Every single customer of ours has my personal cell phone number and they know they can call me at any time. They know they can get a real straight answer from me because I’m the only one who’s touched their engine and been with them through the entire process.”

That process is done primarily in-house as American Speed Shops has several machines to work on short blocks such as a Sunnen CV 616 cylinder hone with a DH series diamond honing kit, a Sunnen CH100 align hone, a Rottler boring bar, a mill, a Storm Vulcan surfacer, and a CWT balancer.

“The only thing that we have to outsource machine work-wise would be any sleeve work and valve job work,” he says. “We have a local shop that we work with who also came from SAM Tech. He’s only 30-45 minutes from us, so he takes care of all of our valve jobs. We have access to a couple of dynos, but we do not have one in-house yet. We’re currently in the middle of building an assembly room and office. We have an assembly room now, but we’re looking to expand it, which is a good thing. The next step after that will be getting a seat and guide machine – something to take care of all the head work we need to.”

Due to the shop’s close proximity to Vengeance Racing, LSXperts and a couple other similar shops, Smith’s main goal and focus was to cater to them so they didn’t have to call somewhere out of state.

“We’ve done some work for LSXperts and we’ve done some work for Vengeance too, but we ship more out of state than we do locally, which is the opposite of what we shot for in the beginning,” he says. “But we’ll take that. It’s definitely just about getting your name out there.”

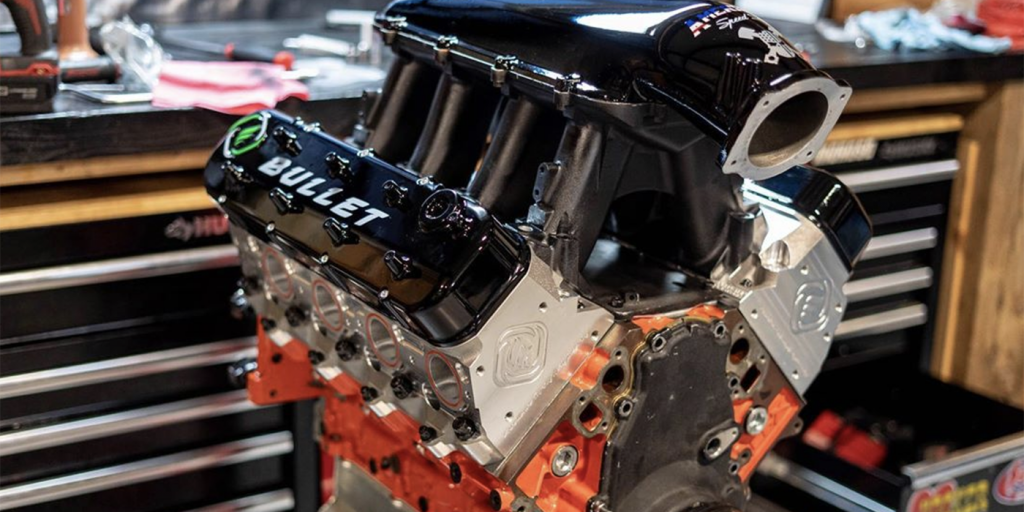

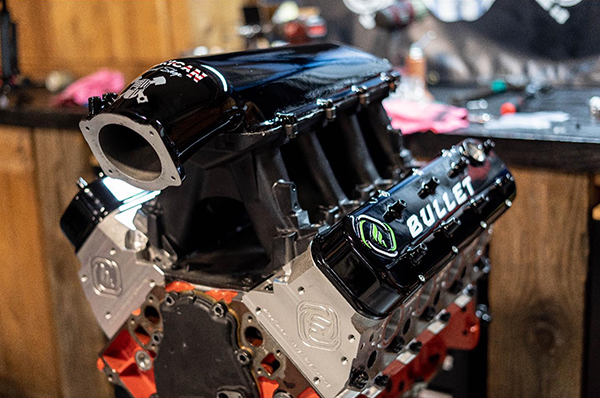

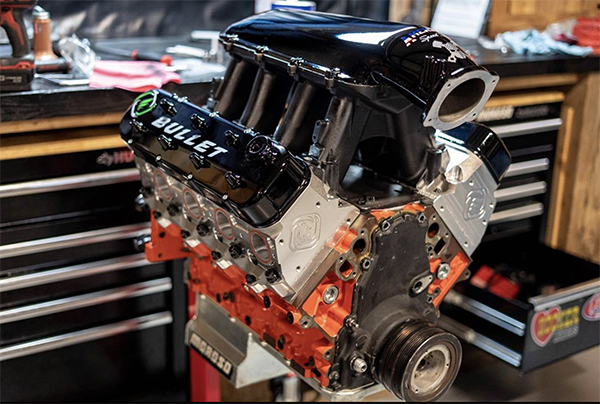

And getting their name out there is exactly what American Speed Shops has done. With a focus on late-model GM stuff as well as some Coyote and Hemi work and a new partnership with Z1 Motorsports for Nissan and Infiniti engine work, Hunter and Chris have kept busy. As part of gaining more recognition for the shop, they did engine work for a customer named Juan who owns a fairly well-known Trans Am WS6 car named The Bullet WS6.

“We were just starting out with our shop and we had been following some Trans Am posts on social media,” Smith says. “We have a few shop cars that are WS6 cars. We had been following Juan and his WS6 car. I reached out to Juan one evening and just mentioned if he ever needed anything to give us a shout at the shop. It was the right time and right place and he mentioned he needed to do a refresh and change some things up for the next season.”

Hunter stresses he wasn’t trying to steel business away from any other shop, but just making sure potential customer’s knew American Speed Shops was available to help out. The effort got Juan’s business and he ended up sending the shop his engine.

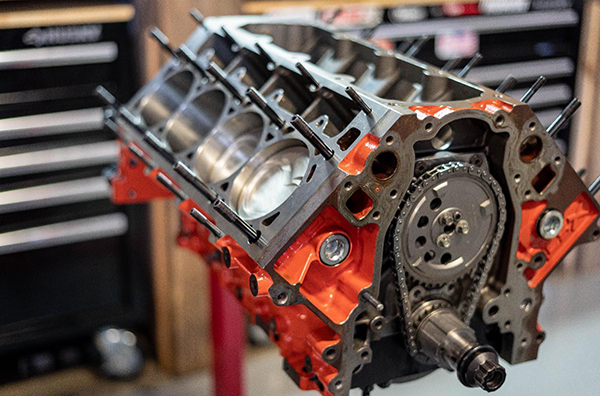

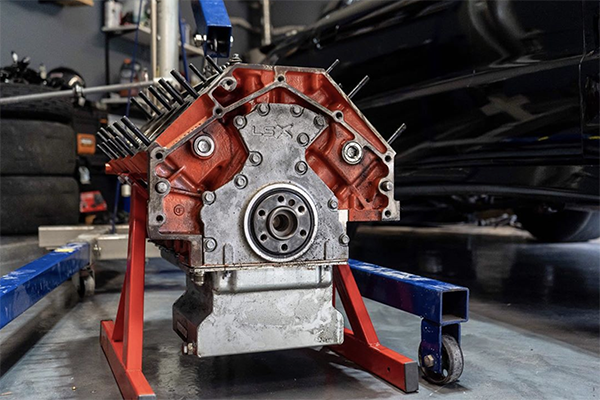

“Our biggest and most well-known build was Juan’s 427 cid LSX engine,” Smith says. “We just had the engine in for a refresh. The engine was pretty worn out at that point. We opened up the engine and saw some glaring issues we didn’t like such as a double roller timing chain, which we try and stay away from, and some other little things we changed for the better. But the block got all the machine work – we cut the caps, align honed it, torque plate honed it, squared the deck, and deburred the entire thing. We checked the balance on it and found an issue there, so we rebalanced the crankshaft and cleaned it for assembly.”

The LSX features a Callies crankshaft and Callies connecting rods, Wiseco custom pistons, new cylinder heads from Frankenstein Engine Dynamics, a Holley hi-Ram intake manifold, and custom American Speed Shops valvetrain and camshaft ground by Brian Tooley Racing.

“We’re thinking it should make around 1,300-1,500 horsepower with the new cylinder head set up from Frankenstein,” he says.

The engine also features a twin turbo set up, which means The Bullet WS6 will be tearing it up on the drag strip!

Engine of the Week is sponsored by PennGrade Motor Oil and Elring – Das Original.

If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].