Engine of the Week is presented by

I first spoke with Bryan Neelen, owner of Late Model Engines in Houston, back in 2018. Since then, we’ve kept in touch for Engine Builder stories. When I saw that Bryan had completed another gorgeous engine build, I couldn’t pass up the opportunity to showcase the build.

Bryan’s entrance into the engine building industry started when he was young. A friend of his told him about the School of Automotive Machinists & Technology (SAM Tech) and his decision to attend laid the ground work for his future.

“I came down to SAM Tech and really took a liking to it and really just put everything into it as far as spending the amount of time in class,” Neelen says. “I spent morning till night up at the school and I just took it all in, and then got a job here in Houston at a performance machine shop doing a lot of circle track-style engines and big cubic inch nitrous engines.”

It didn’t take long for Neelen to begin to do some side work doing cylinder heads, and after a few years building up equipment and clientele, in late-2003, Late Model Engines was born.

“We literally started with absolutely nothing,” Neelen says. “It wasn’t like we just took out a big loan and said, bam, we’re in business. We just built it up slowly. It was a process.”

While cylinder head work continued to be a mainstay, Late Model Engines soon got into block work and then evolved into the entire engine. Officially opening in 2003, it wasn’t until 2004 that Late Model Engines finished getting the rest of the equipment it needed to truly be in ‘full swing.’

In 2017, LME moved into a new 17,000-sq.-ft. facility with more than 10 employees.

“We really have an excellent, excellent crew,” he says. “We’ve got guys that have multiple NHRA championship titles to their name, as far as our engine builders go. We have incredible cylinder head porters. We do all our own five-axis CNC machining of the cylinder heads and all the digitizing port development in-house. We do all of our billet intake manifolds and valve covers. We’ve got multiple Haas four-axis CNCs and we also have a SuperFlow EFI engine dyno.”

As the name suggests, LME specializes in late-model, domestic, V8 and V10 engines, with a large focus specifically on LS and LT engines. The shop will also take on occasional Viper, Ford modular and Hemi work as well.

“I’d say 90 percent of our work, even 95 percent, is still all LS and LT,” Neelen admits. “We’re powering a lot of the highest horsepower, fastest LT engines in the world.”

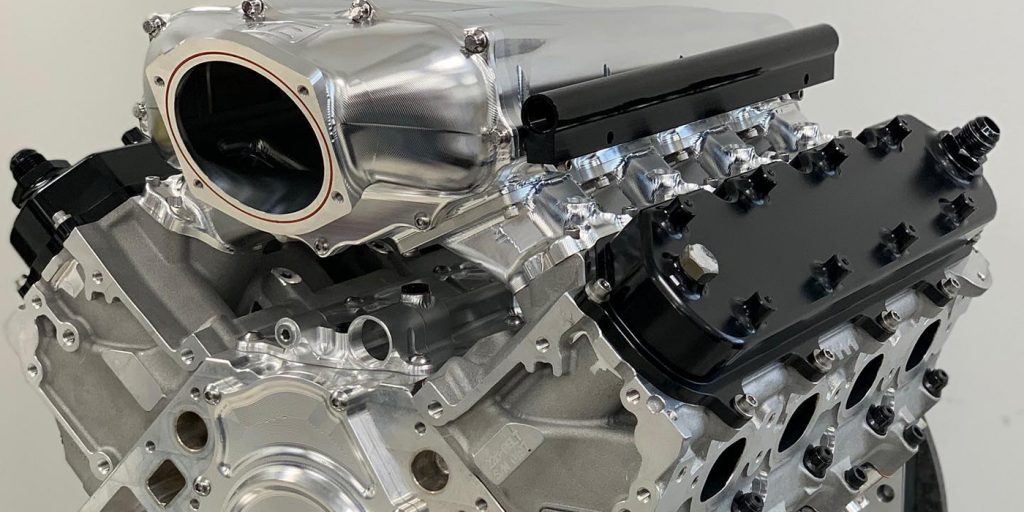

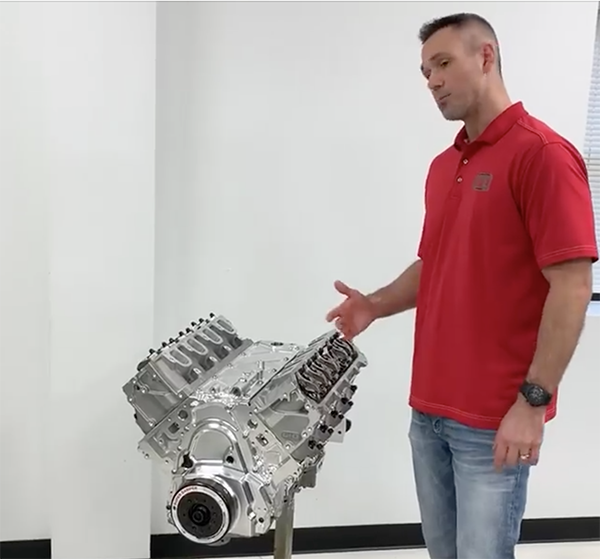

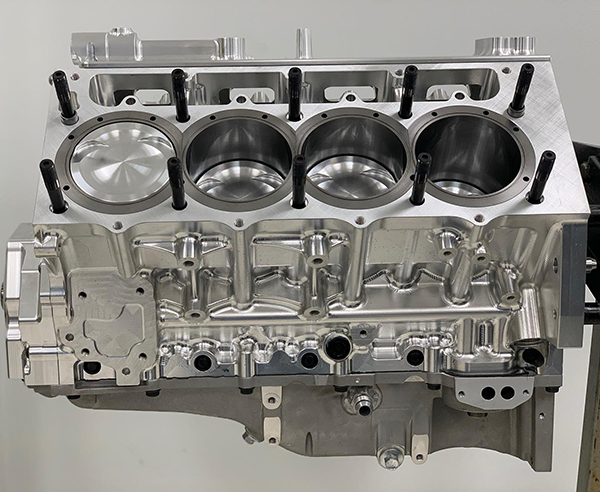

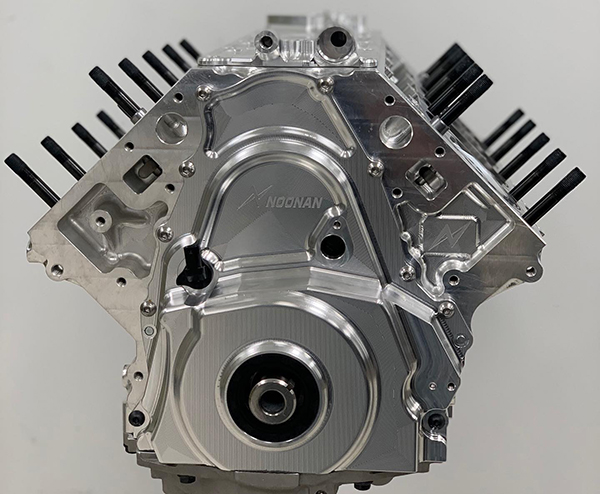

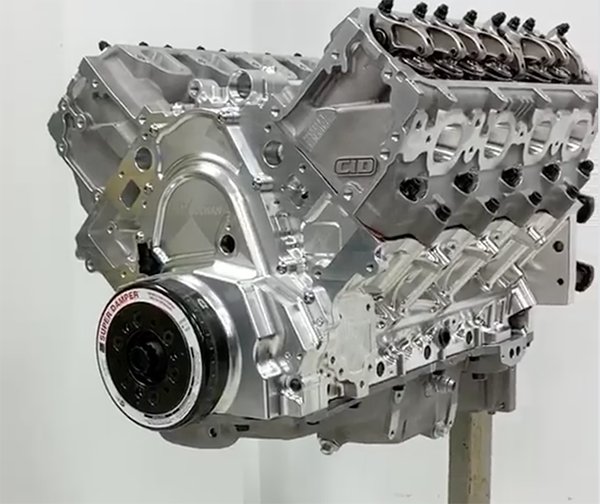

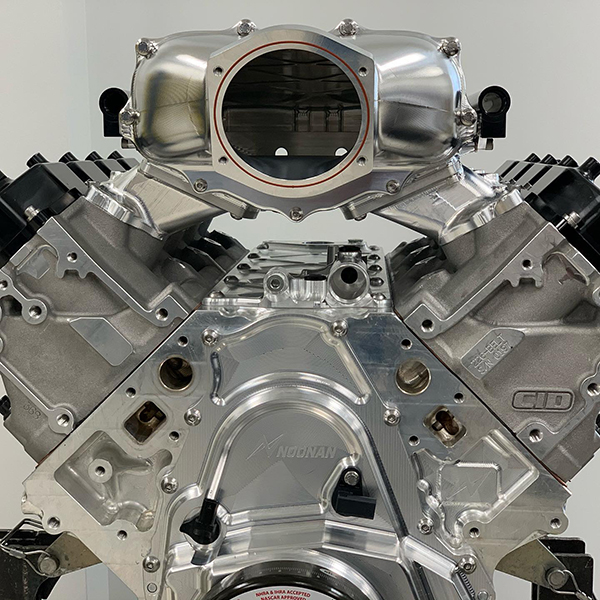

One of the shop’s latest creations is this LTX 416 cid engine based off the Noonan billet, 6-bolt per cylinder block, which Bryan was very excited about announcing. The build is for a customer named Tim King.

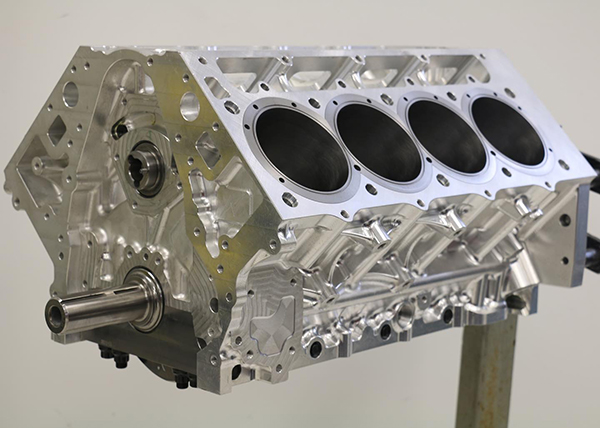

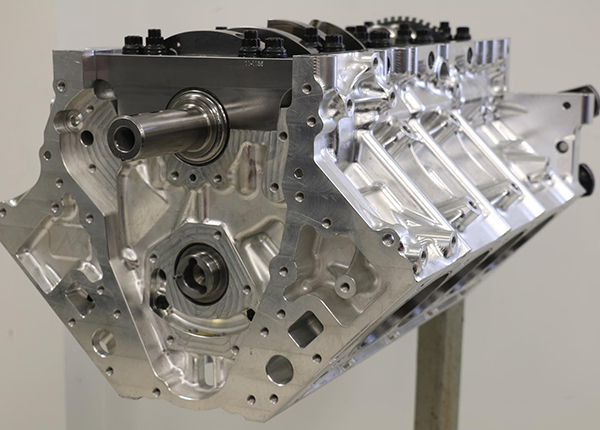

“A couple features of this block are the 6-bolts per cylinder,” he says. “It’s something we’ve been waiting on for quite a while. It utilizes the same pattern as the standard LSX 6-bolt pattern, but now with the LT. We’re running half-inch head studs.”

In the bottom end, this block features half-inch main studs and billet main caps. LME is using a Callies 4.000˝ stroke center-counterweighted billet crankshaft, Dyers 300M billet connecting rods, custom Diamond 2K forged pistons, Total Seal stainless chrome rings, tool steel wrist pins, and Clevite H-series main and rod bearings.

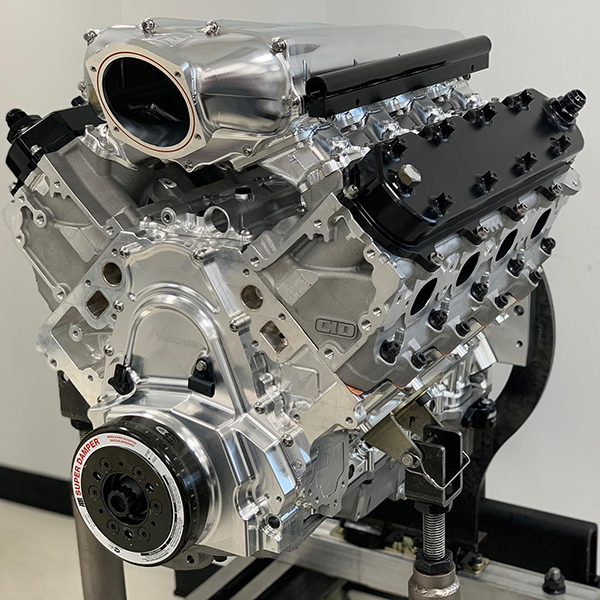

“Up top, we’ve got CID cylinder heads, which were CNC ported in-house,” Neelen says. “We do all the development and CNC porting in-house on these cylinder heads. We’re running titanium intake and Inconel exhaust Pac dual valve springs and .937˝ lifters. This is set up for a low-lash, solid-roller application using Manton 7/16ths to 3/8ths tapered pushrods and their billet steel rocker arms.

“The block comes with its own billet valley cover specific to the engine block, and it utilizes [Noonan’s] front cover for the raised cam.”

The 416 cid LTX engine features a dry sump oiling system and will be going into a twin-turbo Corvette.

“We’re looking to set some records with this combination,” Neelen says. “We’ll be pushing over 2,000 horsepower at 8,000 rpm. It’s going to be one hell of a combination. This engine will be broken in on the dyno for a break-in and then sent out to the customer.”

Here’s to hoping it sets some records very soon.

Engine of the Week is sponsored by PennGrade Motor Oil and Elring – Das Original.

If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].