It’s no secret in any aspect of performance that everything after the engine becomes the weak link when you start adding power, and quite often, the transmission is next in line. But when it comes to the power and torque of a modified diesel, I thought there might be a little more to this version of the game, so why not find out from someone who knows?

To narrow my search for an expert, I typed “live, eat, breath, sleep, work and drive diesel” in the search bar and it brought up Pure Addiction Diesel Performance in Hillsboro, Oregon. (Not really, it actually brought up some type of yoga site and breathing exercises). But the description is correct and the staff at Pure Addiction Diesel Performance are dedicated enthusiasts. The owner, Travis Turner, turned his passion into a business and took some time to talk to Engine Builder about the subject of transmissions.

Confirming what I expected, Turner pointed out that it’s mainly the torque and the weight of the truck that combine to wreak havoc with the resulting shock load that will quickly find the weak spot in a transmission. “The transmissions are designed to handle a lot of power and torque from the factory,” Turner says, “but when you turn the horsepower three, four, or five times more than what the factory designed it for and you have double or triple the torque, you start to have problems.”

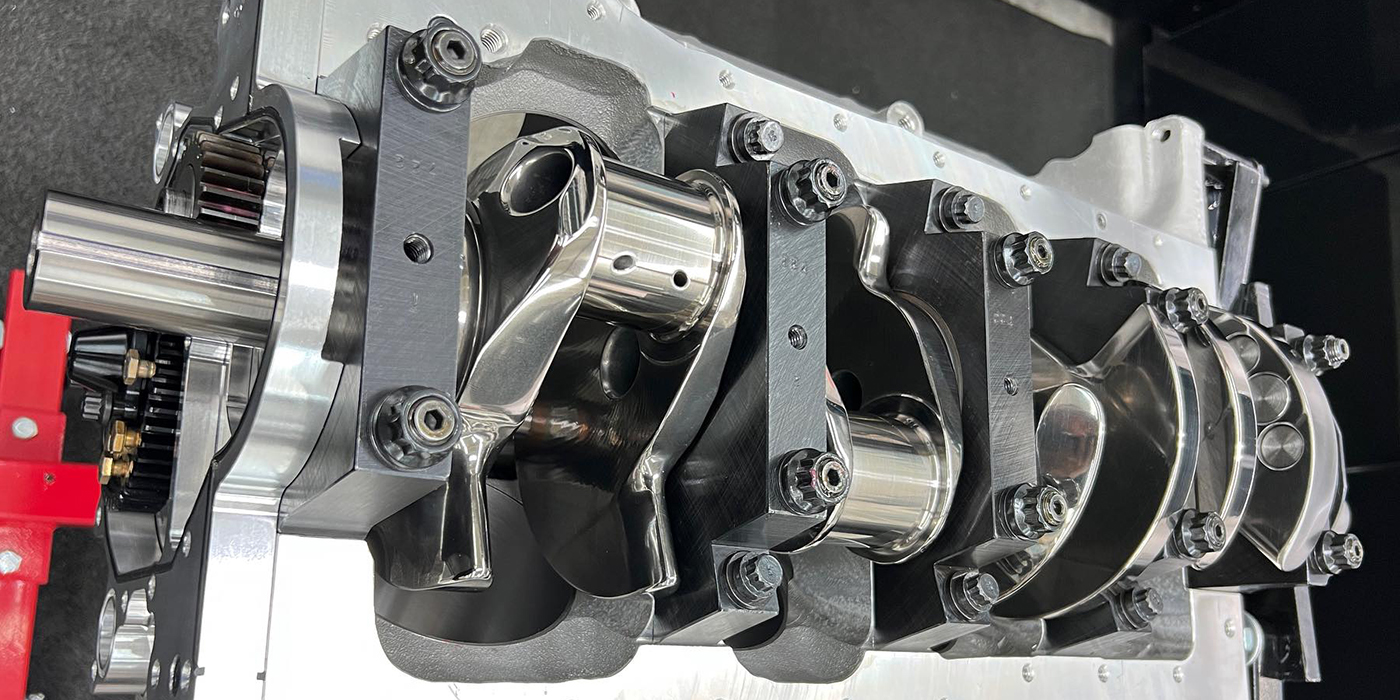

Turner explained that typically over the 500 horsepower range, there are valve body modifications, transmission tuning and line pressure modifications you can do to allow the factory units to handle moderate power increases, but once you get much above that range, you start to get into more hard parts such as different style clutches, more clutches, billet shafts, billet stators and triple disc torque converters.

Today’s world of information has customers much more informed than they have been in the past, but I still know that educating and informing them is a big part of what performance shops do, and I wondered if there may still be the guilty few in this market that only concentrate on engine modifications and overlook the rest of the truck.

“We like to advise our customers that they need to budget for a transmission before they begin to perform any modifications,” Turner says. He points out to his customers that depending on how they drive the truck and how much power they want, they are going to need a transmission to handle it.

“Sometimes when we do the modifications, we build the transmission at the same time,” he says. “And sometimes customers opt to build the transmission first and then do the performance modifications afterward.

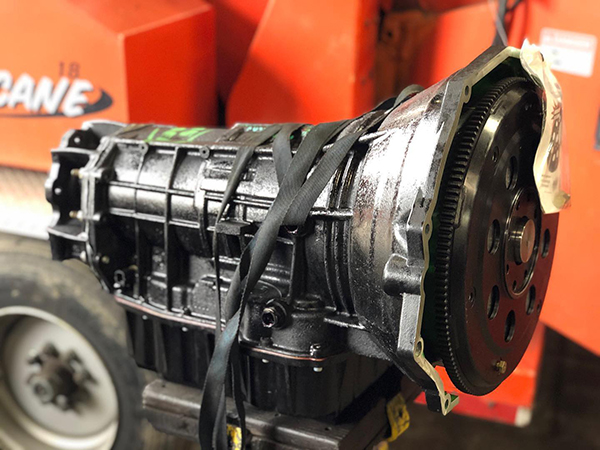

“When we build a unit, we always try to figure out what the customer uses it for, what their horsepower goal is, whether they are ultimately going to be drag racing or sled pulling or exactly what they are going to be doing. We build the unit to handle their ultimate goal instead of building the unit where they are at and having to go back into it later.”

It’s not uncommon, as with any type of performance market or vehicles, to single out specific transmissions that are more durable or have different characteristics and swap them into what you are working on. This has been common with some of the diesel trucks over the years, but Turner explained that it is not as common as it once was.

“There used to be a lot of transmission swaps for different units,” Turner says, “but as time went on there’s been a learning curve on the newer transmissions and swaps aren’t as common in this day and age.”

Turner explained that one of the factors driving this is that a swapped transmission never works as well as it does if you modify the factory transmission. “There are always little communication issues and creature comforts with the original transmissions that you lose with a swap,” Turner says.

OEs have been making great strides in developing transmissions that continue to handle more power and torque than ever before, and in addition, aftermarket manufacturers invest heavily in the research and development of new products, figuring out how to make them handle higher horsepower.

“Aftermarket parts manufacturers are tearing apart transmissions and making parts as soon as new units appear,” he says, “and they are doing a great job and making these units so they can handle the power and last, and swapping is not as necessary anymore.

“Most of the units we build are for the average 500 or 600 horsepower truck that people tow heavy loads on the road with.” When it comes to popular modifications, tap shifters are a very common upgrade for towing vehicles. Early trucks didn’t have tap shifters, which allow you to shift with the push of a button. This is standard on newer trucks and works great for not only towing but drag racing and daily driving as well.

“For towing, it’s nice to have that manual control,” he says. “Especially if they have a larger turbocharger, if they want to keep up in the rpms a little bit, they have the control to stay right in a specific range and keep it in a specific gear.”

Manual controls are very popular for drag racing and there are a lot of different options for TCM programming that provide features such as second gear start, which is also a common tactic and advantage for different forms of racing and competition.

I asked about transfer cases and Turner explained that typically they are a little more durable than transmissions, the shaft sizes are usually pretty large and they’re not very complex, so they don’t see a lot of transfer case failures.

Pure Addiction Diesel builds about 300 transmissions a year and they have a dealer network that they sell them through. “We don’t sell carry out units to the general public,” Turner says. “The dealer network ensures professional installation and cuts down on the failure rate.”

Professional and proper installation is critical and when a new transmission is installed, flushing the fluid cooling system, getting any contamination out and making sure it has the proper flow is vital to ensure proper performance and longevity of the unit. “There are multiple thermal bypass valves in cooler lines or in coolers, and we’ve seen them hang open,” Turner says. “If this happens, the fluid won’t cycle through the cooler and you will have elevated temps.”

Turner emphasized that one of the keys to keeping a transmission alive is not overheating the fluid. When you overheat it, the fluid gets thin, line pressure drops and the fluid breaks down. Transmission temperature is probably the biggest cause of failure.

By having their transmissions professionally installed, they also know that rebuilds are performed correctly and line pressures are correct, and dealers are also required to perform thermal imaging on the coolers to make sure they are properly transferring heat.

Even when transmissions are built, one of the biggest factors that is overlooked and not properly maintained, Turner explains, is transmission temperature. When Pure Addiction Diesel builds a new transmission, they install temperature stickers on the torque convertor and the case. Overheating causes the warranties to be void, and they always highly advise their customers to keep an eye on transmission temperature.

The best place to monitor fluid temperature is at the pan, and most factory units have sensors in the pans, with most aftermarket pans having sensor bosses. Pans are another common modification and have additional benefits on top of locating a sensor. “Aftermarket transmission pans have a drain plug and additional fluid capacity and they are cast so they seal better and add rigidity to the transmission cases,” Turner says.

I asked Turner for his thoughts overall on performance diesel transmissions. “There’s lots of options out there for parts,” he says. “Eight years ago, in racing, if you had a 1,000 horsepower engine, you really had something. Now, a 2,000 horsepower truck is where it’s at. The manufacturers of transmissions and engine parts are really involved in R&D and have stepped up their game. The evolution of parts is really crazy. It’s nice that they are keeping up with the demand for what it takes to handle this horsepower.” EB