SOFT SPOT FOR YOU

To improve the appearance when balancing connecting rods or other metal objects, adding a ‘soft spot’ to one end of your belt sander can help. Machining the end of the plate down about 1/8˝ will give you a ‘soft spot.’ Finish sanding the part in the ‘soft spot’ can give you a better appearance when balancing rods or whatever else you are processing.

Lyle Haley, The Shop Doc, Andover, MN

TAKE YOUR CAP OFF

After being disappointed with a cap splitter, I found the best way to remove tight caps. Clamp the cap in a rod vise and put a rubber-coated hammer handle inside the rod. Put pressure on the rod by prying against the vise. Then, smack the rod side to side with a brass mallet or dead-blow hammer. Separated!

Scott Ouellette, Powerplay Machine, Wilmington, MA

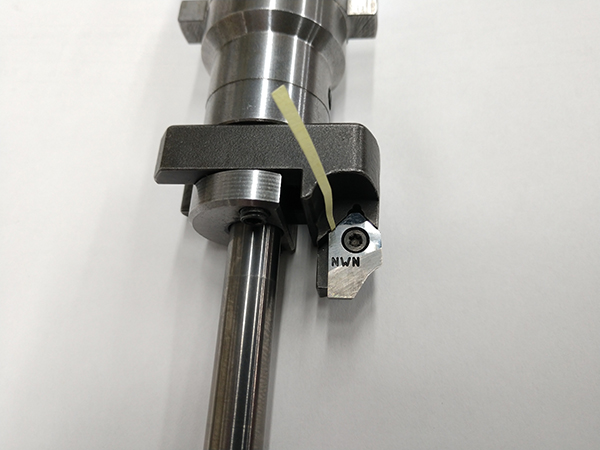

IT’S OK TO CHEAT

Cheat the tool bit with a sliver of paper to change the angle slightly. Post-its or any thin paper seems to work well. I like to run my valve and seat angles the same. Tool bits and holders can vary and this helps with the results, if I need to change it.

Randy Torvinen, Torvinen’s Machine, Menahga, MN

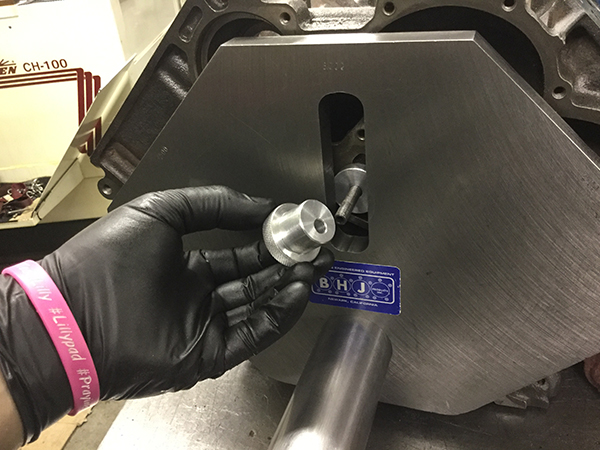

ANOTHER HOMESPUN MANDREL

We do a lot of crankshaft snout rebuilding. To make the process easier, we keep some homespun mandrels that screw into the snout of the crankshaft so it is held secure for welding and machining. Also, using a copper washer between the mandrel and snout keeps the weld from going further then you want.

Adney Brown, Performance Crankshaft Inc, Ferndale, MI

BLOCK TRU OHC ECCENTRIC

I made an eccentric for the front of an Audi block to set up the block true fixture. It uses the original slot as there is a bolt hole directly behind it. Several variations could be made with a smaller diameter eccentric and a slot in the plate to fit about any 90° OHC block. This ensures you’re machining the decks exactly 90° from one another and lets you ‘split the difference’ to get there if they are not correct.

Ron Flood, Cedar Machine, North Branch, MN

PANDEMIC MARKETING 101

“When the going gets tough, the tough get going.” This phrase is a popular witticism in American English and it’s also a popular Billy Ocean song. In today’s context, it refers to the state of our business and specifically, how to stay productive and profitable in these tough times. Now is the time to pick up the phone and call your customers and prospects. People who would normally be annoyed at a sales call are now willing to talk. They want to tell their personal story and want to hear about your business and how it relates to their own. A suggestion would be to make a short list of key topics to discuss, including: is your business open, how are you dealing with COVID, how is your family and what can I do to help? Let them know you/he/us are essential, you can get parts and maybe offer pickup and delivery. Look for prospects that are essential like farmers, truckers and delivery services. Offer a promotion like free TP with every valve job! Your business is essential to the continued operations of our country. Let your customers and prospects know you are here to help.

Steve Rich, Sterling Bearing Inc, Kansas City, MO