Inside Mike Moran’s Motor City Billet Bullet

When you’re an innovator and a visionary such as an Edison, Franklin, Da Vinci, Gates or Jobs, the road to building something for the first time isn’t always an easy one. People doubt you, you have little support, time is against you, and in many cases, the physical materials necessary aren’t even available yet to achieve the end goals. Not many understand these barriers to innovation quite like Mike Moran of Moran Motorsports in Taylor, MI.

In 2009, Moran began down the path of building an engine like none other before it. It would require time. It would require belief that it could be done. It would require support from others in the industry. And it would require new products to be innovated right along with it.

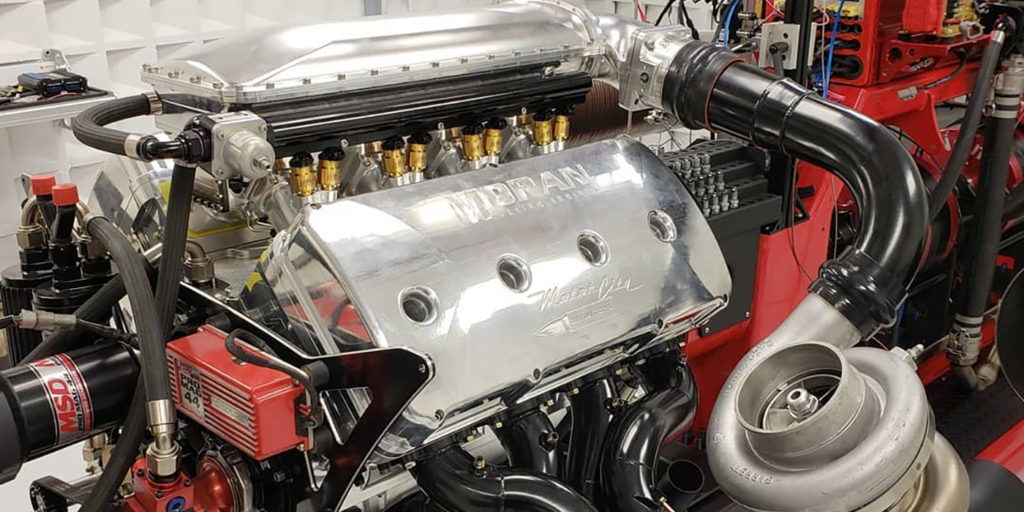

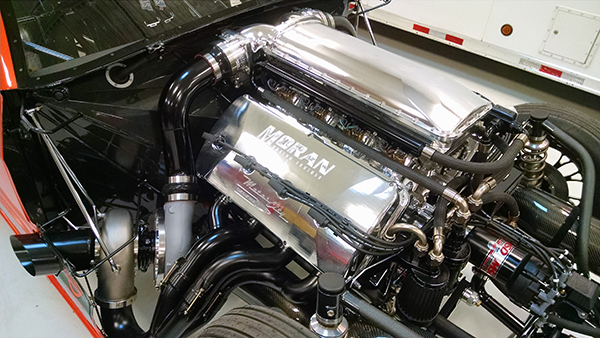

Moran was designing the first-ever, 100-percent billet engine capable of 4,400 horsepower! Nicknamed the Motor City Billet Bullet, the engine would be for Moran’s personal use in an Outlaw Pro Mod application. The build aligned with Mike’s interest in being first to break industry barriers.

“I got an idea for this engine after I had been running all the different engine combinations and all the parts out there,” Moran says. “They’re all great combinations, but they all have shortcomings and most of them are because of what the rules organizations will allow. I just took everything that we’ve looked at, seen or done and said, ‘Let’s start with a clean slate and make an outlaw motor. I know we can’t race it in NHRA, but I’m sick of these combinations that have these shortcomings and you can’t fix them because they won’t allow you to change the architecture.’ That’s where this engine came along. I wanted to draw the perfect engine combination.”

Moran’s clean slate catchphrase was, ‘It’s got a little of three and some of me,’ meaning bits of Ford, Chrysler and Chevy, and the best of Moran’s own innovations.

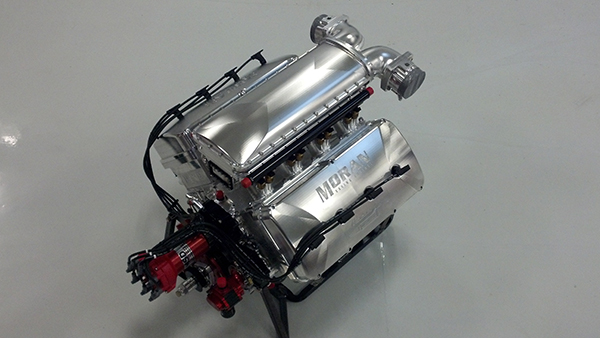

“We wanted to have the first all-billet engine because there wasn’t such a thing back in 2009 when I started,” he says. “You had billet engines as far as blocks and heads and that was it. Intakes and pans were sheet metal. Valve covers were cast. When you’re doing something like this, the advantage is you’re drawing it all anyways, so it didn’t matter that you were going to make all these other parts as well because you had to draw them before you build them. I would just contract different people in the industry to build the parts and that’s how we kind of evolved this thing to where it’s at now.”

As easy as that sounds, Moran ran into numerous road blocks for his engine design, both in components and in finding an engine dyno capable of running an engine at over 3,000 horsepower.

“When you build something from scratch, there’s no, for lack of a better word, infrastructure ¬– there’s no support at the ready,” Moran says. “There wasn’t a dyno that existed to run an engine with that much power. There weren’t turbos big enough to support that much airflow through an engine. I took a leap of faith building this combination because you’re in for the long haul. It was five or six years before I was able to get a dyno in place that actually could hold that kind of power because it wasn’t an industry standard, it didn’t exist.

“I approached all the dyno companies and none of them were interested because I was the only one asking for something like this. Land & Sea listened to me and worked with me. My idea was to take two 3,000-horsepower absorbers and run them in tandem. Land & Sea were the only ones that didn’t look at me like I was crazy. They worked with me and it took us a year and a half to get everything in place and then work through all the bugs. We did a bunch of redesigns on our end because they just did the best they could with what I wanted. That was a work in progress for nearly two years.”

For the engine itself, Moran contracted local machine shops to machine his designs for the engine block and various parts. The engine is 670 cid and features a 5.300˝ bore center. Moran designed everything to be perfect such as making sure the bore spacing from the driver’s bank to the passenger bank was even in such a way that he could use center rods.

“All the engine combinations out there whether it’s Chrysler, Ford or Chevy, they’ll use offset rods because their banks aren’t shifted the correct amount to center the rods,” Moran says. “Obviously, with a clean slate, you do stuff like that and then it just builds from there. The engine doesn’t follow anybody else’s plan. Instead, it follows the perfect path.

“For example, it’s got 10 head bolts similar to a Ford, but they’re 5/8th studs instead of 7/16ths, so they get torqued to 250 ft.-lbs. for ease of maintenance so you can have the heads on and off without moving the intake, but yet you don’t sacrifice the clamp because you’ve got a bigger fastener.

“In the front of the engine with the accessories, there’s always been a problem with sharing the camshaft for magnetos and fuel pumps, so you get into all these elaborate drives. With this engine, I put a remote drive off the side so that a guy could run either a fuel pump or a mag and leave the cam open to run the other. It’s a lot cleaner up front.

“In addition, the cam is raised up in such a way that it wouldn’t be considered a .400˝, .600˝ or a 1˝ raised – it’s more like a 3˝ raised. It’s up there to where the pushrods are laying horizontal practically, and they’re much shorter than you would find in any other engine. That adds a lot of stability to the pushrods. The engine features a lot of cool stuff like that.”

The engine block was done by Charlie Weston of Weston Machine who also worked closely with Dan Jesel on the camshaft and lifter layout.

“What Jesel did at the time was never even heard of,” Moran says. “It was a clam design – clamshell 82mm cam. You’ll hear about it more often now, but back then, nobody even knew what it was. Jesel did all the valvetrain for me and the camshaft and lifter layout.”

Internally, the engine features an all-billet Dailey oiling system, a Bryant crankshaft, Diamond pistons, GRP connecting rods, and Speed Pro bearings. However, the coolest aspect inside the engine has to be how the oil drains.

“One of the things that Danny Jesel worked with me on is the cam-driven scavenge pump that’s in the back of the engine about where the transmission would be,” he says. “The whole area is machined out like a valve body. I’ve got it so the head drains, the block drains, the valley drains – all the drains – go to that back area. It’s got two 5/8ths rifle drillings from the front to the back that catch all the oil and then deliver it to the back. In essence, there is not one drop of engine oil that drains over the rotating assembly. It all goes to a reservoir in the back that’s all internal to the engine and is driven off the cam. Danny designed that pump for me and it’s a key thing. You’ll never see it anywhere else.”

In fact, Moran says some engine builders will try to keep oil from draining over the top of the rotating assembly using lines and similar things, but this system is completely internal.

“You’ll never see a line anywhere and it keeps all the upper half oiling and lifters and all that from ever draining any oil across the reciprocating rotating mass,” he says.

The Motor City Billet Bullet engine at this point was more or less put together, and Moran had worked with Land & Sea on a capable dyno set up, however, one key element was still not in place – the twin turbos.

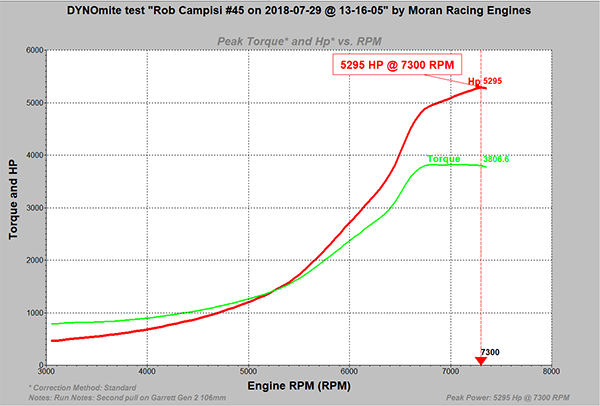

Using Garrett’s Gen I turbos, Moran was able to run the motor on the dyno successfully to the tune of 3,700 hp, which was 700 hp more than any dyno could hold before, but still well shy of Moran’s goal of 4,400 hp.

“We found out that the limiting factor were the turbos,” Moran says. “We had been lobbying Garrett for the prior three years about having a bigger turbo that flowed close to 300 lbs. per minute worth of air. Of course, it took them three or four years to do that because nobody was asking for those.”

In the meantime, Moran tested the engine using Garrett’s Gen I turbos as well as their Gen II turbos, which were smaller than the Gen I versions. Using the Gen II turbos, the Motor City Billet Bullet picked up power and went over 4,000 hp.

“We knew the engine would be capable of more,” he says. “But the turbos really weren’t there. Eventually we got a surprise package from Garrett and they had sent us the new Gen II 106mm turbos. We threw them on for what ended up being the last day we could dyno before I had to do a bunch of NHRA engines, and we made two different pulls over 5,000 horse with those. The rest is history.”

When Moran started this engine design in 2009, his goal of 4,400 hp was based off of the current turbo technology at the time. The more efficient they keep making the turbos, the more pounds per minute they keep putting out. With Garrett’s new turbos becoming available, Moran’s horsepower goal had changed, and the engine made 5,295 hp at 7,300 rpm.

“Somebody might be thinking, ‘Why can’t you take those 106mm turbos and put them on a smaller motor?’” he says. “Well, you could, but then you’re at the limit of the architecture of that engine. They’ll blow the mains out or they’ll start pushing gaskets and moving stuff around. That’s why I built this engine so it could do what it did. When you try and push that much air through some of that other stuff you’re going to be replacing parts or fixing stuff because it doesn’t have the bigger port volume and the camshaft that we do.”

The two pulls over 5,000 hp were made in July 2018. Moran has since made some adjustments to the valvetrain and changed out the camshaft.

“We had Danny Jesel make us the new valvetrain that we wanted and we did a slightly different cam,” he says. “We ran it on only 28 lbs. of boost and it made 3,370 horse like that, which was up probably 150 hp from where it was before at that point. Then, we looked at some of the valvetrain stuff and wanted to make one more change on the cam before we ran it hard up to 9,000 rpm and 70 lbs. of boost.

“We changed to a low-profile cam and changed ramp speed. From there, we’re just working on valve spring life. In the past, the motor could run up past 8,000 rpm with no problem. Once you’re done with the pull, however, the springs are down 150 lbs. It’s a little abusive on springs.

“What we’ve done is worked on smoothing out ramps and we changed some ratios around so it wasn’t so violent and then we re-ran it. Since then, now the thing will go to 9,000 rpm two or three times at the same boost level it used to without killing the springs. They’re just slightly fading, so we saw room for improvement.

“We’re hoping this last iteration is going to be a home run. What I’m looking for – and I know it sounds crazy – is an almost 6,000 horsepower engine that you don’t have to change valve springs on or do any work on. I don’t know if I’m going to achieve it, but I’m in the right direction.”

Years in the making, many barriers broken and still possibly more to come, Moran describes the Motor City Billet Bullet build as a fairy tale the way it came together.

“I knew it’d be a long road,” he says. “I jumped in with both feet before I realized I was going to be designing dynos. I never thought I was going to have to wait for turbos to come out. I guess it’s better I didn’t look. I just leapt into what would be the best architecture and engineered engine, but it was worth doing for a first!” EB