OHC LIFTER PULLER

When I disassemble an Ecotec head I always have trouble getting the lifters out. There is not enough room for my small fingers to grab on and sometimes they are stuck with varnish. I use 1/4˝ fuel hose, about a 6˝ length, to slip over the tip of the lifter. Out they come. If they are really stuck, this allows me to work them up and down while spraying them with carb cleaner. It works on other engines with those small lifters too.

Helen Just, Union Auto Supply, Union, MO

MAKING IT SIMPLE

When I build my bobweights, a simple piece of PVC for a stand makes it easier. Just zero out the scale and add the weight.

Randy Torvinen, Torvinen’s Machine, Menahga, MN

WELDING ROD WEIGHTS AND MEASURES

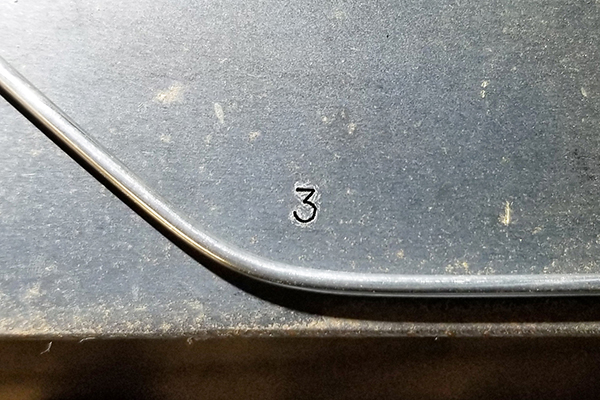

First, find the length of your welding rod that is equal to one gram. On my welding bench I stamped the numbers 1 through 5 for that distance to give me a visual reference of the weight of the welding rod. As shown in the picture, if I wanted to add 3 grams of weld to the crank, I would lay the welding rod over the numbers and put a bend in the rod at the number 3. I then pour the rod into the weld until I reached the bend and then I know 3 grams of weight was added to the balance job.

Lyle Haley, The Shop Doc, Andover, MN

BLASTING OBSERVATIONS

Here’s a couple of tips regarding soda blasting. Soda is very fine and it can become very cloudy and difficult to observe your work. I have drilled fresh air intake holes around the periphery of the viewing window, which helps keep the area clear. I also created a vibrating device using an old fan motor on to which I added a cable end fitting to generate the vibration. This causes the expended material to quickly return to the reservoir. Professional vibrators are available in many intensities, but I preferred to build my own. This submission is prompted by one of my customers asking a variety of questions, while observing me conduct some soda blasting. I have four cabinets. One each for baking soda, chilled iron and two types of glass media.

Archie Frangoudis, Archies Racing Service, Nashua, NH

SAVING YOUR STONES

On the Sunnen CK-type honing head, the stones are a one shot install. We all have that box of good single stones though and various ways to reuse them. I take a single strand of copper wire and lay it in the “teeth” of the stone holder and then re-insert a used stone. Snug again. You can make pairs and use up good single stones.

Ron Flood, Cedar Machine, North Branch, MN

TONING UP AN LS

On LS crankshafts we are balancing, I always use a tone ring alignment tool to check that the alignment is correct. Then, we place two equally spaced welds to ensure the ring stays aligned. High rpm LS engines have been known to spin the tone ring.

Jake Sampson, Sampson Racing Engines, Inver Grove Heights, MN