All Aboard the Valvetrain – Part 2

In our June issue, we put a spotlight on valvetrain component selection – specifically camshafts, lifters and valve springs. Of course, there’s more to the valvetrain than just those parts. Enter valves, rocker arms and pushrods! All of these components work in conjunction and the selection process for the proper parts can sometimes be daunting and complex. But valvetrain selection can also be boiled down to a few simple facets that if followed, can greatly help your selection process and keep your engine out of failure trouble.

Valves

The selection of the proper intake and exhaust valves require taking into consideration the spring pressure applied when the valve is on the seat and in the open position. Numerous valve materials and coating variations are available depending on the specific requirement for a given engine.

“Titanium valves are good if the builder is trying to save weight and isn’t worried about cost,” says QualCast’s Adrian Long. “Stainless steel is a more robust material if the builder is looking for durability, longevity and cost savings. Sodium-filled valves are another option and Inconel is called for if you’re working with exhaust valves. Stellite, which is a super durable, premium alloy on the face of the valve, is necessary for corrosion and high-heat applications.”

According to Dan Gathman, vice president of operations at Elgin Industries, their PRO-STOCK performance valves are made from 21-4N material, which is best for heat resistance. They’re also swirl polished to aid in air induction into the cylinder.

“Valve choice for size (length) will depend on if you are using stock springs or are adding length for extra lift (spring installed height),” Gathman says. “For material selection you should never substitute a lower grade then originally specified by the manufacturer, but you can always go to a higher grade for longer life and increased heat resistance.”

In addition to the valves themselves and their composition and design, you’ll also want to look at valve seat composition. Are you going to run a real tight tulip on the exhaust? Are you going to run a radius margin or a square margin on the valve?

“There are so many finite details on what you’re trying to do that it can literally make or break you on whether or not the engine makes horsepower,” Wilson says. “For a street application where I want to push a little bit more horsepower, we will suggest running a bronze guide to keep things cooler, softer and better for the valves. If you’re making a lot of max-effort power, we like running a MoldStar 90, which is an alternative to beryllium. CHG also makes a fantastic valve seat.

“In terms of the valves themselves, you have to decide whether you’re going to run a tight tulip, a wide tulip, an undercut, a radius margin, etc. – there’s so many things to look at. These decisions are also dependent on what type of combustion chamber you’re working with as well.”

On exhaust valves, you have what’s called a margin, which is basically where the valve seat angle meets the outside diameter of the valve face. On the bottom side of that, which is actually exposed to the combustion chamber, some valves have a 90-degree edge and others have a radius edge.

“What we have found throughout the years is if you can form a radius on the end of the valve, airflow will get around the valve a lot faster,” he says. “That will also help with spool if you’re running a turbocharger, and it will also allow exhaust gas velocity to increase around the valley for instances like a nitrous application.”

Taking a look at diesel valves, Alderson says he typically utilizes Inconel intake and exhaust valves or Inconel exhaust and stainless intake valves.

“With a lot of the Powerstroke stuff, we’re working with a very small bore size, so you’re fairly limited on valve size without going to a considerably larger bore,” Alderson says. “We try to offer drop-in options that don’t require reinventing the wheel. We can do a stellite facing valve or a full stainless valve. We’ve done different one-piece valves and we’ve done different two and three-piece valves. It depends on the application.

“A lot of the factory valves only have a flash chrome plating, so we do a bit of a deeper chrome plating to them, which helps for wear and resistance. For something that’s going to run higher boost or get taken to the track occasionally, we like a stainless, nitrided option. If it’s an all-out, maximum effort, competition engine, we go with Inconel.”

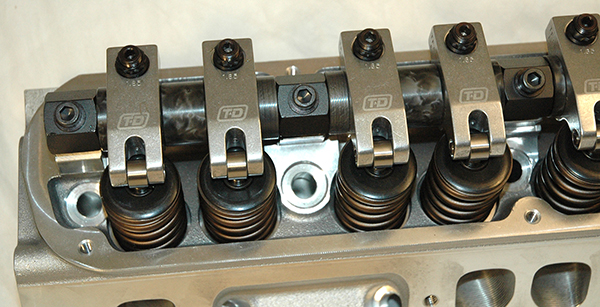

Rocker Arms

In many engine builds, strict attention is not paid to rocker arms. They are not thought of as contributing to the durability, longevity, consistency, and power of a race engine. But top engine builders hold the opposite to be true or they wouldn’t be where they are.

“Many believe the ‘lowly’ rocker arm is just a lever to transfer motion from one direction to another,” says Phil Elliott of T&D Machine Products. “But a fully qualified engine builder who designs an engine for a specific application knows the contribution that proper rocker arms make to the overall combination. Due to engine builder preference, and that T&D is flexible in manufacturing, most of our rocker arms are custom built.”

Getting the camshaft’s full lift/duration to the valves, means proper installation and setting of the rocker arms is an important facet to reaping 100% of available power.

“High-stress applications demand a somewhat different rocker arm,” Elliott says. “For example, supercharged or nitrous applications may require a steel rocker body. That can also apply to off-road, boat and oval track racing. It removes flex from the valvetrain, while adding longevity. Many applications don’t require going that route, but if your application will operate in those high-stress arenas, or if cylinder pressure is going to be very high, steel rocker bodies will be an asset to the combination.”

In fact, just about the entire market over the last seven to 10 years has shifted to steel rockers, but aluminum rockers are also still widely used.

“We always were a fan of the aluminum rocker, but the applications are constantly warranting something better,” McDonald says. “Aluminum rockers are still our biggest seller, however, the industry is shifting toward steel rockers. All the high-end motors – Pro Stock, Sprint Cars, Pro Mod – are pretty much all steel rockers now. You can’t beat the longevity of a steel rocker. The steel rocker has really found its place.”

While steel is the go-to material these days, there are many different styles of rockers for engine builders to choose from.

“There’s still a lot of people that run stud rockers,” he says. “However, certain applications will warrant getting rid of stud rockers for shaft rockers because studs can’t handle the stability, high rpms and the spring pressure. You’re going to need something more rigid and something that can locate and lock down a lot better like a shaft rocker. A shaft rocker holds its lash a lot better than a stud rocker ever could. A shaft rocker also gets rid of all those guide plates, poly locks and girdles to keep the stud rocker stable.”

A pedestal-style rocker is another option available, which is often seen on LS engines. Like everything else, rockers can vary greatly depending on application.

“Within each level of our rockers, you can choose to lighten them or not to lighten them,” McDonald says. “If it’s a supercharged application, you don’t want to lighten them, you want them heavy because there’s a lot of a deflection and cylinder pressure. There’s also an option between a cup and a ball adjuster, again, depending on lift and application. The ball, the rocker and the cup on the pushrod help with angle and to keep the rocker stable.”

If your looking for stock replacement options for your rocker arms stamped rockers are an option and are many times available in different ratios and slot lengths so you can customize your valve lift and have the clearance needed for higher lift applications.

“The next step up,” says Gathman, “is a stamped, roller-tip rocker, which reduces the rolling friction at the valve stem. These give a slight advantage in horsepower that would otherwise be consumed in the valvetrain, and they extend the wear life of the valve stems.

“The best choice for spring pressures up to 800 lbs. and more are stainless steel roller rockers. These are fully machined from billet and have roller bearings for pivots and at the valve tip.”

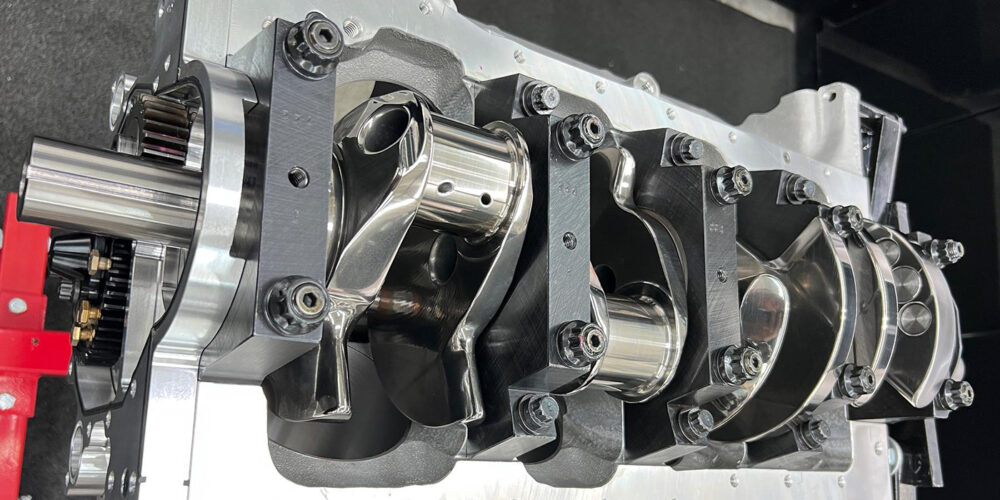

Pushrods

Pushrods are another piece of the valvetrain puzzle. Pushrod engines tend to get some flack for being outdated, but there are plenty of advantages to them. Pushrod engines tend to produce good low-end torque due to better air velocity at low rpm. Increasing the velocity of the intake air means the air and fuel mix better, providing better combustion and torque.

Another advantage is the simplicity of the engine design itself. A pushrod engine is a much simpler solution than a dual overhead cam engine. That’s not to say one is necessarily better than the other or more or less reliable, though.

A pushrod is required to transfer motion from the camshaft’s lobe to the valve. The pushrod’s length, wall thickness and end configuration, along with the material it’s made of, are all specific to the application. Like valve springs, there’s nothing overly fancy about pushrods, but they are an essential element of the engine’s design, reliability and performance.

Pushrods are required to transmit the reciprocating motion of the valve lifter to the rocker arm. Both ends of the pushrod form a connection, which accommodates the angular movements of the pushrod in response to the straight-line motion of the lifter barrel on one side and the arc motion of the rocker arm on the other.

Since the pushrod is part of the valvetrain, it’s exposed to vibration and shock from the opening and closing of the valve against extreme coil spring pressure. Due to the energy necessary to open the closed valve at a fast rate, the pushrod has to endure excessive force while still accurately transferring the motion created by the camshaft profile.

Today’s pushrods are strengthened in critical load-bearing areas and utilize a number of design features in application-specific uses such as: one-piece pushrods made from chrome moly and tool steel; bronze-insert, chrome-moly pushrods; double-tapered, 7/16th pushrods that are case-hardened; straight, double-taper or offset-taper configurations; and standard and tapered pushrods in varied wall thicknesses.

Due to differences in engine design, pushrods can vary in length. The pushrod’s length, along with the rpm potential of the engine, are critical design factors.

“When rebuilding an engine, especially if using non-stock parts or milling the deck or heads, you should choose a pushrod length that prevents the rocker arm slot from bottoming out when either in the closed or open valve position,” Gathman says. “If the pushrod is too short, you’ll face improper valve opening, rocker slot wear and stud wear. If the pushrod is too long, you can break the rocker when it bottoms out in full lift position.”

If you’re upgrading the camshaft and springs in your engine, you’ll want to switch from a stock pushrod to a hardened pushrod.

“Follow OE recommendations to start. Higher RPMs and valve spring loads will need more stiffness and strength, which means better materials, larger diameter and increased wall thickness,” says Elgin’s Brier Dieckman. “Then, take into account any changes to the camshaft or other components.”

When it comes to pushrod diameter, it’s usually best to use the biggest diameter you have clearance for. This gives you added strength and stiffness. If clearance is an issue, going to a thicker pushrod wall can help with both as well, according to Dieckman.

“The best material is 4130 aircraft-quality seamless chrome-moly,” Dieckman says. “This is available in our Elgin PRO-STOCK 700 Series performance pushrods and our PRO-STOCK one-piece thick-wall pushrods. Our one-piece pushrods offer up to 40% greater column strength and increased stiffness to virtually eliminate the compression and deflection that can lead to valve float and possibly catastrophic failure. These pushrods also are centerless ground, have fully hard-turned 210-degree radius ends and are black oxide coated.”

Conclusion

Manufacturers are readily available to ensure you pick the appropriate parts for your engine every time. Just keep in mind your application, your rpm range and horsepower goals. The valvetrain puzzle falls into place from there. EB