TRUCK BOX TRUNK

I needed a secure space at the back of my shop to store some tools that could also act as a small workbench. I decide to mount an old aluminum truck bed storage box on the wall. Quick, easy and durable.

John Farmer, LS Conversions, Lenoir City, TN

READY CHAINS

Lifting various configured engine blocks and heads can sometimes be frustrating. One of our solutions was to assemble a number of chains with various popular diameter bolts on ends configured to rotate freely, thus allowing easy attachment to the item. Several of ours are covered with shrink tube to avoid scratching the item being lifted.

Archie Frangoudis, Archie’s Racing Service, Nashua, NH

LS ENGINE STAND MOD

After using all kinds of braces and straps to secure 5-bolt bell housing LS blocks to an engine stand, we ended up making a 3/8˝-thick steel plate that spans the area where the bolt hole is missing and drilling it to take the engine stand arm that was shortened the same 3/8˝. We also made a spacer to take the shortened arm back to it’s original length when using it on standard blocks. We keep the spacer zip tied to the arm to prevent loss.

Dan Cansler, Cansler Automotive Race Engines, Sylva, NC

FILTER CATCHER

When removing an oil filter on the dyno you can make a mess. Our solution was to cut the side out of a 1-quart oil container. This catches any of the runoff and you can place the filter in the container to move it out of the way without any mess. I started using a 1-gallon jug for sprint car engines with oil filters mounted to the dry sump pump because they tend to make a significant mess when they are removed. Just happened to be what we had handy that would do the job.

Adam Cofer, Salina Engine, Salina, KS

TAPPING IRREGULAR SURFACES

When manually tapping on an irregular surface or where you just want it to go in dead straight to the hole you drilled, simply install an old countersink tool in the chuck after removing the drill bit. Then, drive the tap with a box end wrench or tap driver while holding down with pressure from the quill. This will support the tap and keep the drive end from orbiting the centerline.

Ron Flood, Cedar Machine. North Branch, MN

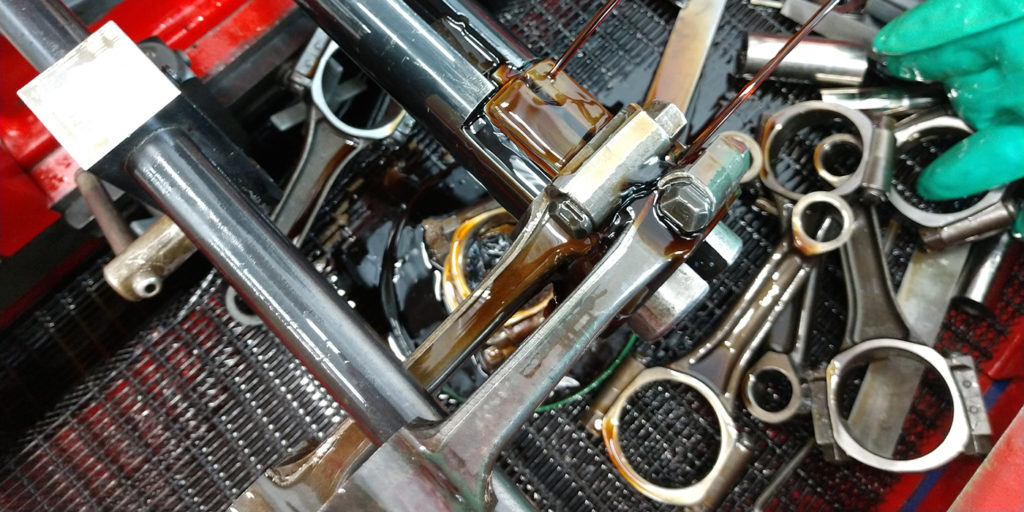

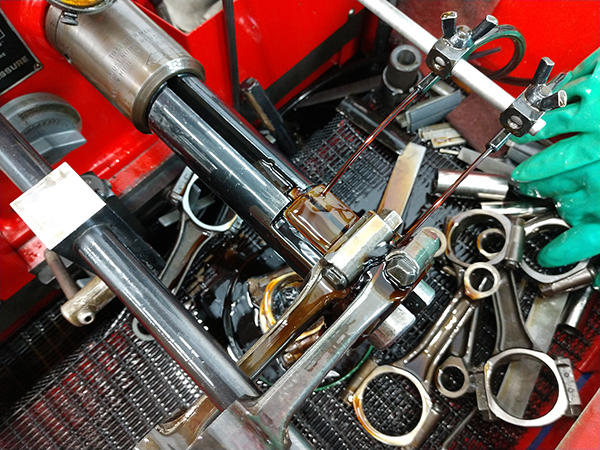

OIL STREAM STROKE STOP

When resizing connecting rods, I set the oil stream to where I want the stroke to end. That makes it simple and is an easy visual reference.

Randy Torvinen, Torvinen’s Machine, Menahga, MN