Despite being an a 25-year-old engine platform – initially released in 1995 – the LS engine remains one of the most used platforms for racing and performance applications, whether it’s street/strip, drag racing, off-road racing or marine. GM has since followed up the LS engine with the newer LT platform in 2014, but the aftermarket has been hesitant and slow to move away from the LS in favor of the LT.

“The LS engine took the best of what we know as far as airflow and valvetrain characteristics from small block engines and aftermarket race stuff and incorporated it in a good beginning platform to start with,” says Luke Siebert of Siebert Performance. “To me, that was the contributing factor for the LS being so popular.”

The LS small block comes in three variations – Gen III, IV and V. The performance improvements of the LS family over the Gen I and II versions are significant. So much so, in fact, that producing over 1,000 horsepower with only a handful of aftermarket add-ons isn’t hard.

We’ve talked with countless engine builders about high-horsepower LS builds, and today’s builders are working with the LS platform to transform it into something more than their customers expected. The parts they use are a significant part of the recipe. After all, what everyone wants to do is make more power.

Luckily for all the engine builders and those looking to get engines built, the aftermarket is loaded with options for LS engines due to the platform’s popularity and the amount of cars the LS engine is used in. There’s too many component options to include in this one article, but we’ll cover some of the more common options for increasing horsepower.

Creating Horsepower with Bolt-Ons

You might be wondering why bolt-on components can make such a drastic difference. Well, when GM engineers begin the development of a certain powerplant, they do so with many external components that don’t have the final durability, refinement, packaging, piece cost, and noise, vibration and harshness canceling devices on them. Some of the more common components like this are the air intake and exhaust systems.

In fact, many of these base components and systems are changed over the course of the GM development and durability evaluation process to meet the extensive requirements for creating production-level powertrains. Of course, GM would love to keep power output as high as possible, but they have to meet extremely high quality and durability expectations first and foremost.

If GM were building racecars, then all bets are off, but they’re building highly refined street vehicles for the public, so powertrain engineers work backwards to end up with quiet, smooth vehicles.

That’s not what all of us are after though. We’re looking for horsepower and the attributes that come with it. Like on any engine, the top end of an LS is where the largest portion of the power potential hides. Companies such as Holley offer a number of components that can help pull out more power in this area.

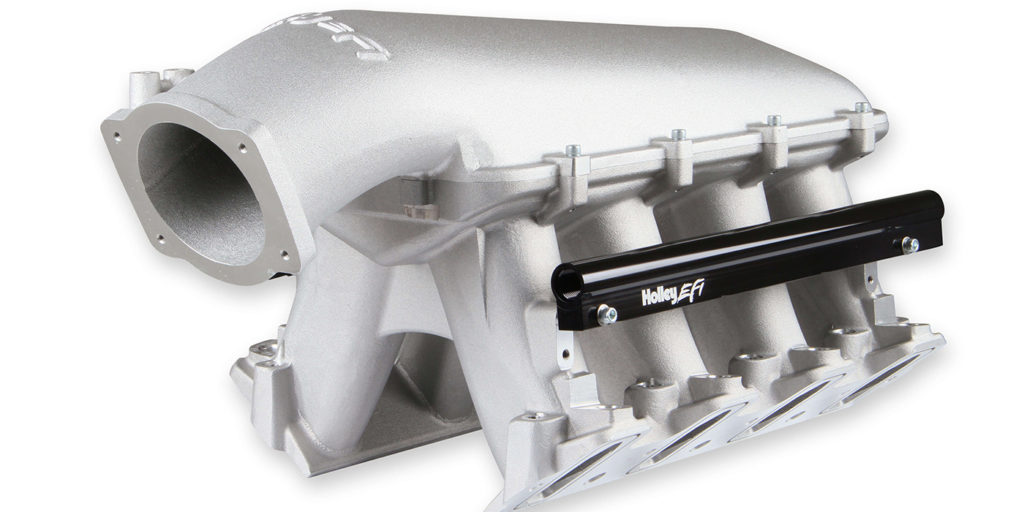

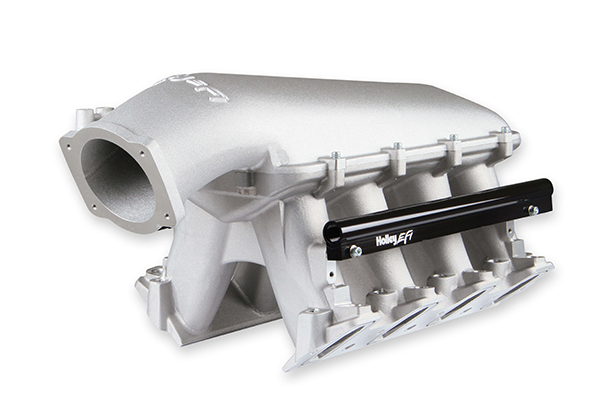

“We have numerous intake manifolds such as our Holley Hi-Ram and MSD Atomic AirForce that pick up significant power on stock engines, but reward even more on modified engines,” says Holley’s Evan Perkins.

When it comes to bolt-on components that make an impact, Perkins says intake and exhaust are the first that come to mind.

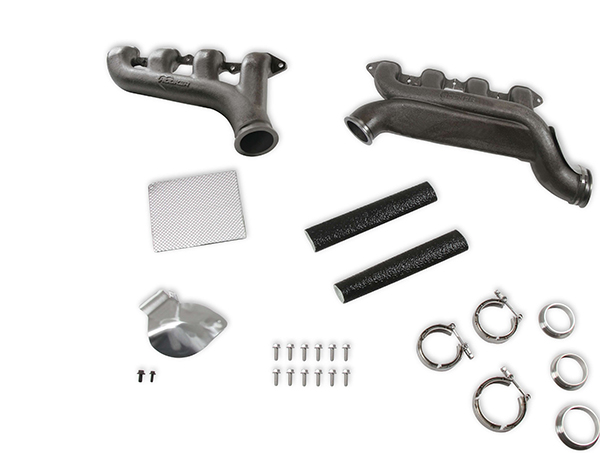

“We offer many cold air induction systems, intake manifolds, headers, and full exhaust systems that offer simple, effective, bolt-on power for a multitude of LS-equipped and LS-swapped vehicles,” Perkins says. “All of our intake and exhaust components are designed, and rigorously tested, to reduce restriction and improve flow. This introduces more air into the engine so more fuel can be added for more power. Our high-flow headers and exhausts more effectively evacuate combustion gasses, also improving power.”

The best part about a majority of these kinds of components is that they generally work well regardless of application or differences among the engine build itself.

“Many of our intake manifolds respond equally well to natural aspiration and power adders,” he says. “When it comes to forced induction, specifically the use of a turbocharger, we offer several products, such as our Hooker Blackheart LS turbo manifolds that make installation so much simpler. When you add boost, the power is going to be there, so quality, fitment and ease of installation become the more important parameters.”

When asked what one product every LS build could benefit from the most, Perkins was quick to point to EFI systems.

“Even with all of the fantastic bolt-on parts on our shelves, if I had to pick one product for an LS build, it would be one of our EFI systems,” he says. “They are so easy to tune, the interface is fantastically intuitive, and they have so many great features such as nitrous control, boost control, programmable inputs/outputs, and we have just about every plug-and-play wiring harness available on the shelf. If you want to build and tune an LS without drama, Holley EFI is it.”

and play control for most domestic

V8 engines.

The Cost of High Horsepower

Obviously, power adders such as turbochargers, superchargers and nitrous are clear choices for adding horsepower to any build, especially LS engines. However, opting to go with some of these power adders could mean big dollar bills as you’ll likely need to do work to the block, heads and some of the internal components to make the engine live at high horsepower.

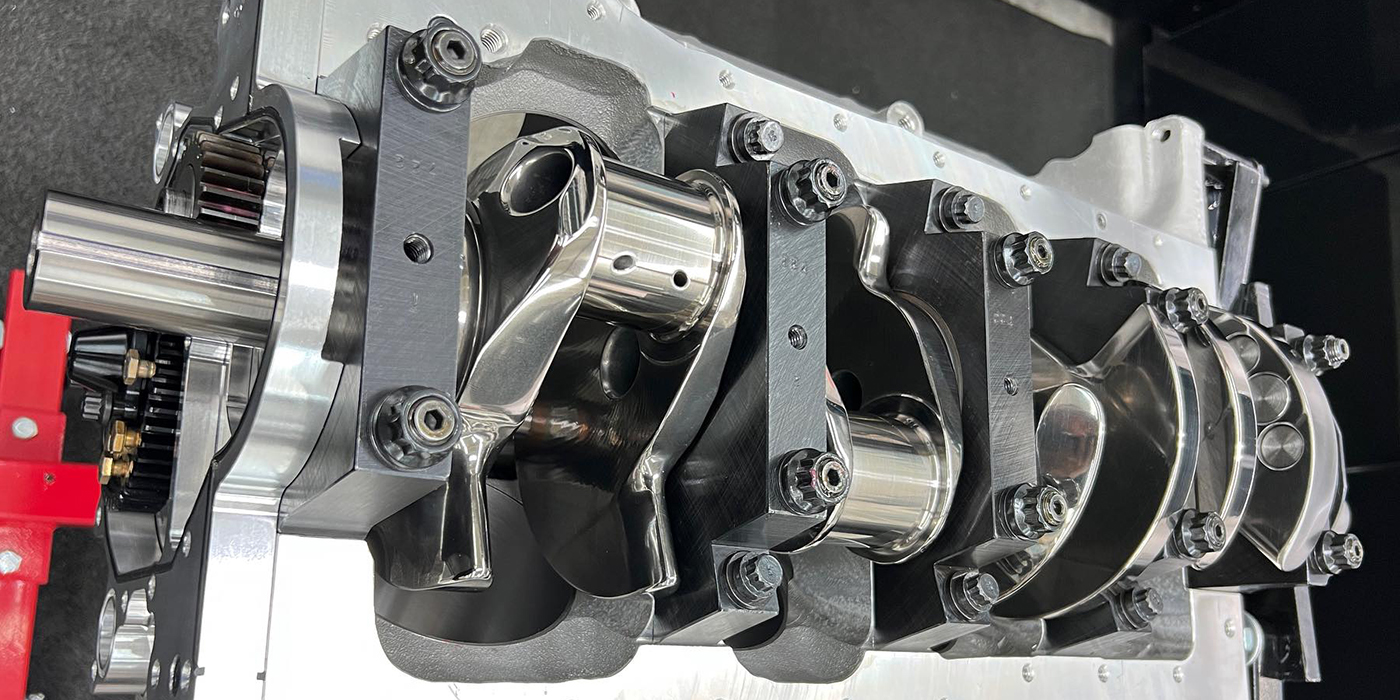

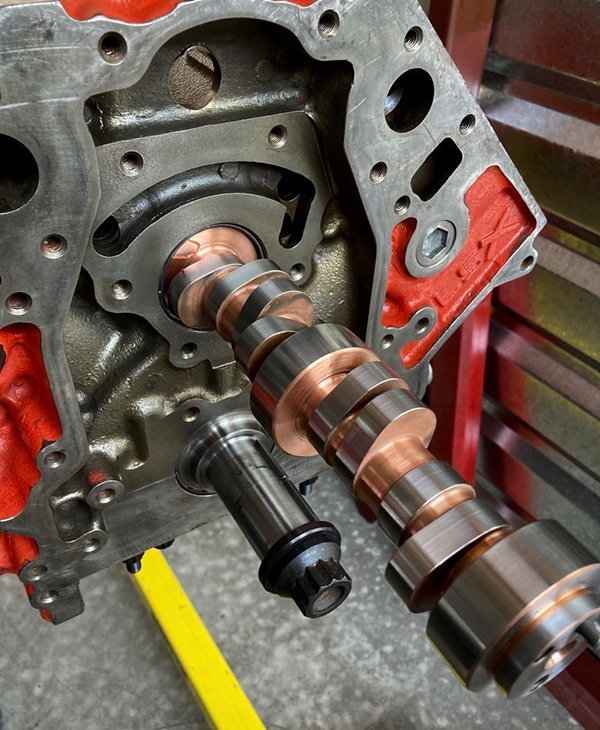

If you do get into a high-horsepower build, aside from the benefits certain bolt-ons can provide, you’ll need to look into upgrading those critical internal components. Nothing is off the table at that level. Crankshafts, camshafts, connecting rods, pistons and valvetrain components can all help achieve big horsepower and keep the engine happy.

The camshaft and valvetrain is where you can make the most impact. Stock LS engines have common camshafts for manufacturing simplicity and cost containment. This creates compromises in power production, but that’s good for performance enthusiasts as there is power available with just a cam swap.

Camshafts are the brains of the engine, so the cam choice you make will seriously affect the power production. If you go with a mild street cam, the idle quality and powerband will be smoother and more predictable. If you go with a more race-oriented cam, the idle will probably need to be higher and the powerband will be peakier, which means most of the gain in power will be at the upper end of the rpm band. Neither is necessarily better than the other, it depends on what you are looking for from the vehicle.

The true beauty of an LS engine is that it’s a really solid platform anywhere from 500 hp to almost 3,000 hp, depending on budget.

“We build quite a wide range of LS engines – anything from mild – just over stock – to turbocharged LS Next block engines that are making well over 1,500 hp to the tires,” Siebert says. “Our biggest market is the higher compression, naturally aspirated LS engines for bracket racing. For our 402 LS motor, we can go quite a ways with it using some very basic components. We’ll start with a brand new GM 6.0L block, a K1 Technologies 4˝ crank, H-beam rods, Wiseco domed pistons, GM Performance LS3 cylinder heads with their port work and their valves, some Brian Tooley dual springs, and a carburetor on gas, and we can make just over 700 horsepower with a hydraulic roller and 13:1 compression.

“Nothing exotic for the heads or block, but it far surpasses what you can do with a small block with similar parts. You’d have to try pretty hard and buy some nice stuff to make 700 horsepower with a small block.”

Again, there are countless options at your fingertips when looking to improve your LS engine. Just be sure you’re increasing horsepower with parts and components that can handle the increase, or you’ll be buying more than you bargained for. EB