Engine of the Week is presented by

We talk all the time about LS engines, small and big block Chevys, Fords, even Subaru, Honda, Mitsubishi, and Toyota engines. These are all great powerplants for a number of applications and are supported well by the aftermarket. But those engines we always cover are typically V8s, V6s and inline engines. Very seldom do we get to discuss the build of something completely different, such as a rotary engine. If you’re not familiar, a rotary engine is an entirely different animal.

When Scott Molitor contacted us and told us he was building a rotary engine for his 2000 Subaru Impreza, we had to know more about the decision to do it, and of course, we wanted to hear all about what it took to make the rotary engine a strong fit. Scott Molitor is the owner of Mofab, LLC in Parker, CO. The speed shop does all kinds of work on a number of different cars and engines, from tuning, engine builds, repair and service work for Subarus to Audis and everything in between.

“We pride ourselves in being able to work on anything that somebody wants to bring to us,” Molitor says. “We’ll take great care of it. We’ll study it if we don’t know it, and if it doesn’t seem like it’s something that we can deliver 100 percent on, we’ll turn it away and send them to somebody who we trust to give them that referral. We like to work on anything that goes fast. We will work on import stuff as well as domestic stuff. It seems to come in waves.”

Scott got into engine building during a time in his life that was a sort of crossroads, he says. In 2001-2002, he dabbled in motocross as a hobby and would build go-karts and weed eater-powered bicycles with his dad.

“That really got me into engines,” Molitor says. “As with anything, if you start to get a little more brave, you start taking more risks and you start getting hurt. I was breaking some bones doing motocross and working a construction job. My parents basically said, ‘You either need to find another hobby or move out of the house and get on with your life on your own.’ Because I had always appreciated cars and engines and stuff, I decided to sell my dirt bike and my truck and buy a car.

“I’ve always been into rally racing. It was something that I followed and I ended up getting a ‘91 Mitsubishi Galant VR4. That was kind of my first foray into the automotive scene and world, and I fell deep down the rabbit hole.”

Scott ended up going to trade school for automotive and worked for a couple of small mom and pop-type shops along the way before he started Mofab, LLC in 2010.

“I didn’t necessarily want to be a business owner growing up as a kid,” he says. “It wasn’t my lifelong dream to own my own business someday, I just wanted to do something with the aftermarket motorsport world. After finally getting my foot in the door with another company, learning the trade and picking up a really good skillset, I decided to go off on my own. Here we are 11 years later and I’ve got five or six guys working for me at any given time and I’ve really grown a passion into a career.”

What Scott loves the most about this industry is fabrication work and TIG welding. His shop can fabricate turbocharger setups, manifold setups, intercooler plumbing, exhaust work, air/oil separation systems, catch cans, tanks, and more. However, the shop, as mentioned, does more than just fab work these days.

“We’ve got four lifts, a Dynojet in-ground all-wheel-drive dyno, three techs, two office guys and a full-time tuner on staff,” Molitor says. “We tune and service anything from Subarus all the way up to Audis like the RS3, RS6 and RS7. There’s nobody at our altitude in the Colorado market currently, that’s doing the custom tuning for those. Our other niche has been the dyno tuning. We have enough dyno tuning work to keep a tuner on full-time and that’s all he does.”

Speaking of ways Mofab, LLC has grown over the years, so to has Scott’s own 2000 Subaru Impreza. The car started as his daily driver, then he did a turbo WRX swap into it, built a roll cage for it, started doing some NASA racing, then door-to-door NASA racing, got his competition license and even competed in the Pike’s Peak Hill Climb. However, that’s when Scott knew he wanted to go in a new direction.

“We built a pretty wild Subaru track car that currently is powered by a twin-turbo 13B Mazda rotary engine that is matted to an AWD 6spd sequential transmission,” he says. The road to get to that point wasn’t an easy one!

“I played with multiple things with the car and what worked or what didn’t work, and we got to a limit with the Subaru powerplant being horizontally opposed,” he says. “The oil doesn’t like to drain from the heads when you’re stuck in a high-load corner. The next step naturally for this car was going to be a dry sump. I was always looking for ways to try to get around the issue, but having done a couple of those setups on some customer cars already, I knew what it was going to take and how much the costs were going to be.

“Even doing the work myself, it was still going to be a significant amount of money. That’s when I started to explore potentially doing a different powerplant, so I wasn’t going to be fighting an oil issue and over complicating things. That’s when I started looking at different engine choices, and with the handling and wanting to keep the front end stock and not move my radiator to the back of the car or do anything too extensive, I decided to try my hand at the rotary powerplant. I always appreciated RX7s and the FD was always a prized car… so I got a rotary engine from a customer of ours to throw in there as a mockup to see if it was going to look right.

“When I sized it up and laid it in there with the cherry picker, a light bulb went off and I thought this was it. I could still keep it all wheel drive. I just needed to find someone to make an adapter plate for the transmission to bolt up to this engine and we’re going full steam ahead.”

Lo and behold, Scott found a company called Subaru Gears in Australia, which makes adaptor plates for basically any engine to mate to a Subaru transmission. One of the more popular adapter plates was for the 13B Mazda rotary.

“I worked with Exedy to come up with some components to make the twin-disc that I already had work clutch-wise,” Molitor says. “A big challenge was getting the starter to work properly because it’s not an adapted flywheel. It is a 13B flywheel, but the tooth pitch and everything was the same for the flywheel as the Subaru, so I just had to basically bump the diameter of where the starter sat in the bell housing further out and was able to use my Subaru starter. That was the most challenging part, honestly, was just making sure I could get that to bolt up.

“I knew someday I was probably going to do a sequential transmission and I wanted to make sure that I wasn’t investing a bunch of time and money into something that was just going to limit me. In hindsight, I probably should have just used Subaru Gears’ flywheel because I could have just put everything together and I wouldn’t have had to deal with the rotational speed difference because of the larger diameter. This actually cranks pretty slow as opposed to the smaller gear, which turns the rotary over a lot faster and they start easier. One thing that is a little tough, especially with a ported engine, is the fire up. But with a solid battery, it kicks over every time.”

Like many folks, Scott didn’t know anything about rotary engines at the time, other than they were simple, but somewhat complicated devices.

“I had heard that it’s black magic and if you screw something up, you’ll spit the apex seals out, which is a real common issue,” he says. “We actually hired a company out of Washington initially to build the first engine for the race car. I thought I’d get these guys to build it and then I’ll maintain it, and when it comes time to tear this apart, then I’ll get with those guys and we’ll go over the ins and outs of doing it and we’ll be able to take the reins.

“It didn’t really work out that way. We spent about $8,000 on the build of the keg, which is what they call the short block for rotary engines. We got it back and got it in the car. All the fab work had already been done, the engine harness was done, and the build was really together just how I wanted it. Everything I had envisioned was really panning out.

“We got it on the rollers, got it fired up and broke the motor in. We were on the phone with the builder the whole time talking about how the tuning was going. This was supposed to be about a 700-horsepower capable two rotor, and it basically let go right at 600 horsepower. Of course, it spit an apex seal out and smoked one of my turbos. I was on the phone with the builder right away and told him what was going on. I could tell he knew he had screwed up, but was hoping it was going to stay together.”

Scott, being a fair guy and a fellow business owner, gave the guy an opportunity to make it right. Scott offered to fly him out so he could tear the engine down with Mofab and see what got messed up or point out why it failed.

“He didn’t want to work with us at all,” Molitor says. “So I grabbed one of my buddies who knew a little bit about rotary engines, turned on YouTube and we got to it ourselves. We tore it down and filmed the whole procedure so I had record of everything, and lo and behold, we found out that he had put the motor together with a bunch of used stuff, which is super common with the rotaries, but there was zero balancing indications, and the biggest issue was the port shapes were completely off. He even braised detonation dents onto the rotors and smoothed them back out.

“I sent pictures to a bunch of well-known rotary guys and they all agreed that was the most ridiculous thing they’d ever seen. I contacted the builder again and told him what was going on and I was able to get my money back for the build. That’s when I built this latest rotary motor myself.”

After recollecting his money and his mind to try the build a second time, the right way, Scott got a brand-new stock keg from a Mazda dealer. They turned the power down to about 400 horsepower and finished out the current season by running a few events.

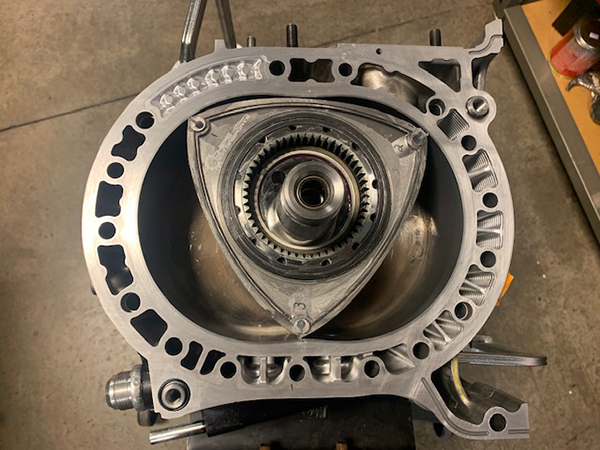

“Motor-wise, it was proving to be reliable,” he says. “The tune was real conservative, but everything was great. That winter we built the rotary engine ourselves. This motor is based off of the factory one that we got from Mazda. We disassembled everything, sent the rotors out to a company out of Michigan called Chips Motorsports to lighten and balance the rotor assembly. He got the rotors along with the eccentric shaft and the rotor housings.

“After the balancing was completed, we did CNC’d exhaust port inserts and port matched those to the rotor housings. It also has a semi peripheral port, which is put into the side of the rotor housing for the intake port. When doing so you have to figure out a way to get that port back to the intake manifold. We hogged out the lower portion of the intake manifold and had these scalloped CNC’d aluminum inserts made and welded those onto the intake manifold. It merges back into one of the intake ports on the manifold itself.

“This is supposed to allow the engine to fire right up and give you plenty of torque down low, but then on the top end it’s supposed to be like hitting the power band on a two-stroke. This engine should pull all the way to 9,500 rpm to 10,000 rpm.”

One of the upgrades Mofab considered was going to a billet block, but the price tag was going to eat into the transmission budget for the build.

“We wanted to go sequential, but knowing the cost of that, we decided to sacrifice a little bit, knowing that people are still having great, reliable setups into the 600, 700 and 800-horsepower range with stock Mazda components,” he says. “Instead, we studded the motor. There’s like 15 of these things that go all the way around the outside of the keg. We’re using ARP studs to hold it together. We also have solid dowels, which is an upgrade that we did to aid in the strength of the block and keep it from twisting itself to pieces.

“For the apex seals, there’s a million different companies that make exotic materials, but a lot of people like the tried and true factory stuff. We went with a company called I-Rotary for the apex seals, which in the rotary world is like your piston rings. These are supposed to not shatter and take out a turbine wheel if they let go. They’re supposed to warp and you lose compression and not be too harsh on the housings and chew the motor up from the inside. If something like this lets go from a detonation event or something like that, it’s supposed to be a soft event. You pull the seals out, replace them and you put it back together, but you’re not destroying a bunch of components in the process. Those seals are a pretty exotic part of the build that we did a lot of research on.”

Scott’s goal was to build an engine he could get two or three seasons out of before having to touch it again.

“Maybe a rotary wasn’t the best choice for that, but I’m trying to prove to people that it’s not the engine’s fault – it’s how it was put together and who’s doing it,” he says. “You have to take the time, measure the clearances, set all the side seal end gaps correctly and set the end play right on the eccentric shaft, etc. All that stuff is what really determines whether or not you have a successful build with a rotary engine.

“You’ve got three side seals per face of each rotor, so you’ve got a lot of seals that you’re filing down to get just right. If you go too far, you’re screwed. You’re doing a lot of checking with a feeler gauge over and over and over again.

“This was a learning experience for me. I had no idea if this was going to work right. Honestly, there’s so few moving components, it’s mainly measuring, clearancing and making sure that you put sealant where it needs to go as it comes together. When you put the apex seals in, they’re two pieces, and you’ve got all these little springs and things – it feels like you’re building a watch. It’s simple, yet it’s tedious and careful.”

When Mofab fired the engine up for the first time a few weeks ago, Scott said it was very satisfying to hear it roar to life.

“This rotary engine is a 1.3L, but it’s a power cycle every time that rotor goes past the exhaust port,” he says. “I wanted a small package that could still fit the front side of the car because the transmission in a Subaru is so far forward. The front axles are driven out of the bell housing, basically, so you’re limited to how much head space you have. The rotary engine is very short like a Subaru engine, so I thought this would probably be a good fit. And the sound that they make is incredible. It’s like nothing else.”

Helping the engine make those sweet sounds are twin Garrett G25-660 turbos. The new G series had just released while Mofab was building this engine.

“I went back and forth with doing a single turbo or twin turbos,” Molitor says. “With a single, it’s simple, lighter and there’s less chance of things burning up because rotaries always run hot. If I spit out a seal, I’m only smoking one turbo, not two. However, if I’m going to do this, I wanted to keep the wild factor going. I thought it would be really cool to do twin turbos, but stagger them like it was an inline motor, so we built a steel dual runner manifold that partitions off to a single, 60mm wastegate.

“Not knowing what we were going to have to do for boost control, I went way overboard on a gate, but I wanted to run one single gate to keep things simple and not run a lot of vacuum lines and stuff. I knew everything was going to have to be hard lined. All the stainless lines for water, oil and coolant on the turbo side of things are all handmade in-house to protect it from the heat.

“The turbos are merged into a single, 3.5˝ stainless steel downpipe that I had ATP out in California do their Inconel wrap on. The downpipe and the manifold are all Inconel wrapped because the rotaries EGTs are so crazy. There’s no valve there to break up the pulses to allow things to cool down. It’s just hot air going out the whole time. That downpipe mates to a titanium exhaust that we built that goes out the back of the car.”

According to Scott, when this twin-turbo rotary engine fires up, you can hear how much air the engine moves. Even at idle, you can hear the ported shrouds on the turbos starting to whine and Scott says, “It just sounds awesome. Hearing them kind of surge back and forth as it starts building boost and as they come online is so cool.”

With the rotary engine in its final stages of being put into the Subaru Impreza, Scott says the engine should make between 600-700 horsepower, and the race car will see track day and time attack events this season.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].