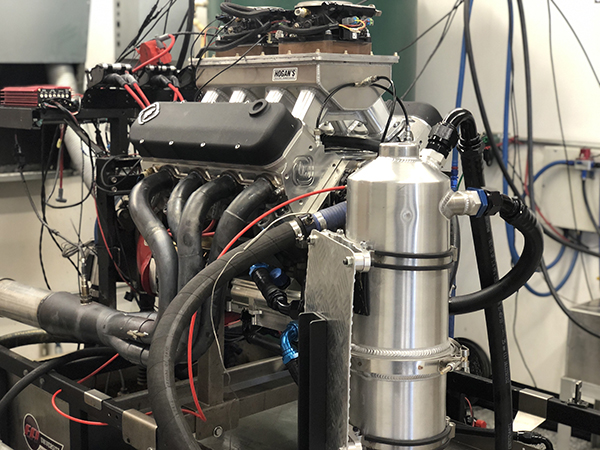

We’re all very well aware of the popularity of the LS engine platform across a number of different applications. However, some of you may be asking why. The answer involves a number of reasons such as the many cars and trucks running LS engines under the hood and the availability of parts, but one of the biggest reasons is the LS engine’s robust valvetrain and the cylinder heads’ ability to harness horsepower.

If you can’t get air in and out of the engine, you have nothing but a hunk of metal. The LS engine does this better than most, and frankly, a stock GM LS casting can be pretty magical if tuned properly. However, sticking to the stock casting has never been good enough for the engine builders and racers of the world.

There’s a million ways to alter cylinder heads for better power, so we spoke with a few cylinder head manufacturers about their LS offerings in the market, why LS heads are so hungry for horsepower and ways you can maximize their efficiency and power potential.

two years in R&D to make sure it was absolutely ready for market.

What’s New?

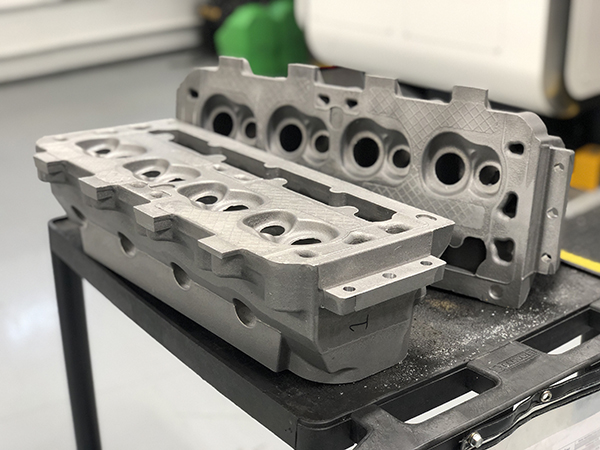

Just as the rest of the aftermarket has embraced components and parts for LS engines, so too have cylinder head manufacturers looking to take advantage of the platform’s horsepower potential and ability to be competitive in almost any application. One such manufacturer is All Pro Cylinder Heads out of Johnstown, OH.

“We got into the LS world because it looked like it was going to be a challenging business and it has been,” says All Pro’s Bob Williams. “We’ve learned a lot over the years. We specialize in hardcore racing cylinder head design, whether it’s naturally aspirated or turbocharged, supercharged, or heavy nitrous. All Pro also has LS heads for dirt modified, late model and sprint car packages.

“We do everything from cathedrals to our own 12-5 series heads, which are an extremely high flowing, large port, small combustion chamber design. Then, we have everything in between. We’ve got LS3-style replacements. We’ve got a retro series for the LS3 and the LS7, which is a direct bolt-on replacement for those applications, and then we go into the LSW-12-1, 12-3 and 12-4. Some of those heads will exceed 3,000 horsepower. Our best-selling cylinder head is the LSW-12-1. There’s probably close to 10 different port configurations that go into that casting.”

Williams admits the All Pro offerings are at the higher end of the spectrum in terms of price, so for the budget conscious out there, EngineQuest says it offers three different LS heads for street/strip applications.

“We offer three LS heads either bare or assembled,” says EngineQuest’s Stephen Richards. “They are optimal for street/strip applications and for people who are looking to get a little more power out of their motor without spending a few thousand dollars. LS heads are capable of making big power because of the way the head is designed in terms of port angle and the chamber makes for better air and fuel mixture.”

One of the newer head manufacturers on the scene is Frankenstein Engine Dynamics. The Weatherford, TX-based company caters to folks looking for all levels of horsepower potential out of their LS engines.

“Our highest volume movers are most certainly our F series cylinder heads,” says Frankenstein’s Mike Shabareck. “They are an aftermarket casting that we developed and designed in-house made out of aluminum. We offer 10-degree versions as well as a 15-degree version in a cathedral LS3 and an LS7 port location and shape. That’s the highest end as far as what we offer for the LS. We also go all the way down to porting sets of GM heads. We also have our M311 head, which is very affordable and becoming one of our most popular heads. It’s an 11-degree LS3 head and is right in the middle of the road for the guy wanting to do an OEM porting service and the guy wanting to get a set of bad boy F series heads. They make great power.”

Making a Better Head

As mentioned earlier, GM’s stock castings for LS engines can make impressive power when tuned well. However, that doesn’t mean the head is without its flaws or areas that could benefit from some improvement.

“A couple of the weak points on heads like the LS7 casting, the LS9 casting and the LT4 casting is in the guides and the valve materials,” Shabareck says. “The guides on those three heads are powdered metal and very strong, but what happens on those powdered-metal guides is they don’t really heat very well into the casting and then into the water jacket. That leads to valve drops down the road.”

The first thing Frankenstein opts to do is put CHE bronze guides in and replace the exhaust valves with an aftermarket one.

“The 821 castings don’t have as much seat press as the 823s or LSAs,” he says. “They’re the ones that have most of the issues dropping seats. That’s been one I’ve tried to steer some guys away from using if they’re going to try to make real big power. If they’re going to do something naturally aspirated it would probably be okay.”

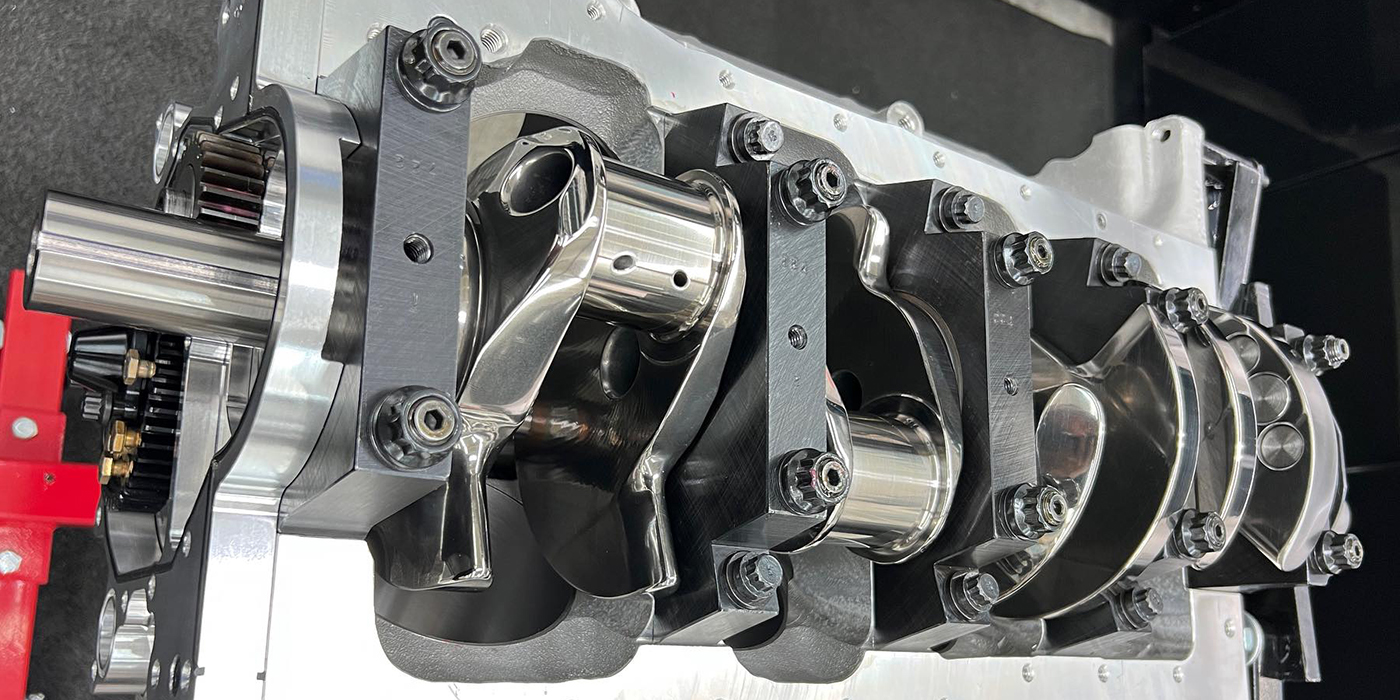

Williams agrees that you need a strong casting to start with and from there you can make significant improvements.

“You need a very strong casting, then port development for both intake and exhaust and then chamber design comes next,” Williams says. “We also do chamber softening, especially for the motors running nitrous, turbochargers and anything that runs e85 or methanol. That’s where the chamber softening becomes real critical because it tends to compress everything towards the center of the cylinder rather than having pockets in the back to collect fuel. From there you need good cylinder head design people.”

The sky is the limit if you have folks in place who know how to manipulate aspects of the LS head to maximize its full potential.

“Because the valvetrain is better in an LS, you can spin it higher, which means you can make more power,” Shabareck says. “You can get away with a lot more mistakes on one of these than you can on something like a regular small block Chevy or a big block or something along those lines because you have that crutch of the great valvetrain.

“The difference is the guys who can take advantage of it by having really good quality air. Those are the dudes who make stuff that really fricking runs because they’re taking advantage of that great valvetrain. You’re allowed to be more aggressive because the rest of the platform can support it.”

Key Areas of Focus

Starting with a strong cylinder head is one thing, but getting quality airflow still has to be the end goal. It’s an enormous factor and a differentiator among variations in LS cylinder heads. Shabareck was kind enough to give us an analogy for proper cylinder head airflow.

“You have to be in control of your air,” he says. “Imagine the air and fuel as a dude white water rafting. The canyon walls get narrower and wider, they make turns and you’re just trying to get to the safe bay. The more turns and the sharper the turns, the harder you’re going to hit the walls. If we’re going to have to hit a wall, let’s try not to hit it as hard as possible.

“The idea is not to fight it. It’s more about the quality and less about trying to hang a big number up there, and what I mean by that is not having turbulent air. You want to have an equal airspeed around the entire area of the port, as much as possible.”

Cylinder head guys gain experience over the years and learn tips and tricks for better airflow, but it’s crucial to become better at the basics and hit the combination of shape, taper, throat size, height – everything together.

“Just like an engine is with a camshaft, a cylinder head, a manifold, the carburetor, crankshaft, etc. – it’s the same way with the cylinder head,” Shabareck says. “We try to assess the whole situation as far as what is going on and it’s part of our name – dynamics – everything that happens inside of an engine is a dynamic situation. There’s thermal dynamics and there’s harmonics, there’s all sorts of different things that are happening here. We have several different pressure differentials inside of one area and we’re trying to maximize all of it to make power. We keep that in mind.

“We don’t exactly get hung up on the flow number. We do a lot more listening to our flow bench than writing down numbers on it. The flow number is like checking your homework at the end. It will certainly tell you if you’ve got something that’ll be a runner or not. But at the end of the day, we focus a lot more on getting quality air charge in and all of the burnt gases out much more than trying to hang a number on a flow bench.”

Of course, manufacturers such as All Pro also refine the intake and exhaust ports for better airflow, but All Pro also puts its cylinder heads through a HIP (hot isostatic pressing) process to add strength.

“All of our castings are made of a premium ingot, and all of our cylinder heads are HIP’d, which densifies the casting similar to a forging,” Williams says. “It comes out better than a billet piece would be, unless you took a billet piece and HIP’d it. It does cost more than a head that’s not HIP’d, but in the long run, it saves the end-user a whole lot of money because the part is going to last. It changes the whole structure of our cylinder head casting and adds strength.

“In addition, we have many different things we can do such as copper seats for the high thermal developers, such as nitrous and turbocharging where we prefer to do a copper seat combination. We also have reversed cooling, maximum weight removal programs and down nozzles for direct port injection. There’s lots of different things we can do to make things better, stronger and faster.”

Something EngineQuest has seen guys do, aside from port work, is change up the springs and utilize bigger seats.

“To get better performance, any builder can upgrade to an aftermarket dual spring or single beehive spring from the OEM spring,” Richards says. “Some people even machine bigger intake and exhaust seats, going from 2˝ intake to a 2.020˝ intake and a 1.55˝ exhaust to a 1.57˝.”

While there are certainly a couple areas of key importance, most cylinder head manufacturers ensure they take a complete, in-depth approach, and even a methodical approach, to what and why an engine or a cylinder head may want what it wants. In other words – they follow the power. EB