In many machine shops across the country, it’s the story of “haves” and “have-nots” when it comes to CNC. While some shops have multiple CNCs and are looking to add more, others are still toiling away with older manual mills and lathes. Those who already have a CNC, and want more, know the value of their machines. They are, in essence, a business in a box, with the only limitations being your imagination. But where do you start?

Let’s say you’re in the market for a new CNC; what features would you want? What are your expectations of this equipment? There are sometimes more questions than answers, so we tried to answer a few of them with our CNC experts’ help.

When CNC started to gain a foothold in engine building shops, many people were skeptical and a little tepid to the idea of a computer-controlled machining tool. The concept of letting go of your hard-earned skill to the controls of a computer was scary. Today, you need an open mind and a willingness to take bigger risks in order to take your engine business to the next level.

When we visited D&J Precision Machine last month and talked to owner Drew Pumphrey, he said they’ve invested heavily in CNC machines to make parts they had trouble getting delivered on time and to the quality they needed. Drew showed us his monster DMG-Mori CNC machine center that looked like it was out of a Marvel movie with a massive 120 magazine tool changer. The day we were there, they were running through connecting rods, which was quite impressive. The fixturing alone to make the rods was unique in that it went through three stages of production to mill them out of a thick block of aluminum. D&J uses the rods in their own builds and sells them to other diesel shops, and they aren’t cheap. Drew says they retail for $3,200 for a set of six. And, as material prices fluctuate, you can’t match the speed and precision of a CNC. He said forged rods aren’t strong enough for the engines he builds, which are in the neighborhood of 2,000 hp.

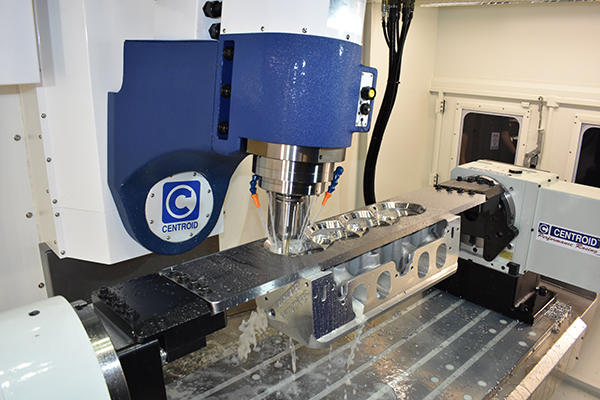

Chris Wright of ProCar Associates in Akron, OH, is a relatively new convert to CNC machining. They recently purchased a Centroid A560 machine to make a production run on cylinder heads they are building for various engine projects, including a multi-valve head that his late father, Chuck Wright, invented years ago and received a patent on. Wright says the 5-axis porting ability of the Centroid is what they needed to reproduce their custom heads and allows them to replicate designs that were hand ported and flowed.

Matt Napolitano of RMC says that many of their customers have come back to purchase another CNC after buying their first machine. He says they also get a lot of shop owners who are unsure of what they need and want as they upgrade from older equipment.

“They know it’s time to upgrade, but it’s a huge process for them to decide because all equipment is more expensive these days, not just CNCs.”

Napolitano says that with the CNC purchase comes a lot of support from RMC in how they can be used to make money. “We know what we can offer with the machine, so we can help them along in making their decision.”

John Cowher of Centroid says from his perspective, what engine builders want today is quite simple. “Certainly, the usual dedicated or specialized machinery, the honing machines, cylinder and line boring, and seat and guide machines, are all staples of the automotive machine shop. We see engine builders buying CNC porting and engine block machines separately or as a combination port and block machine. Now more than ever, there’s a need for the precision and speed of a CNC in three-, four- and five-axis configurations as well as lathes.”

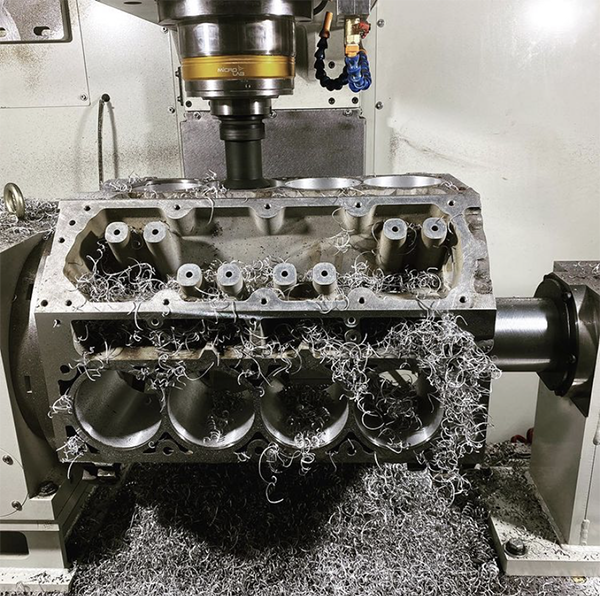

Cowher explains that the features that engine builders really want are not on the front of the menu or brochure. You may need to dig a little deeper. “The features I believe engine builders are interested in are features that make their job easier and the processes easier. A user-friendly interface is a huge requirement, but also, it’s all about precision and consistency. We have features such as coolant thru spindle (CTS) because when you start doing billet work, where you have deep hole drilling operations, having high pressure cooling through the spindle is a great feature to evacuate the chips. If they’re not properly evacuated, it’s going to take you more time. You’re going to recut the chips. You’re going to shorten the tool life and get less than desirable finishes. You can achieve the same results eventually by using ‘peck drilling’ cycles, but it’s going to take longer.”

Another important feature that many shops want is software that helps design and implement parts. Cowher says that the ability to model a part in CAD and then make a tool path from the model is the easiest way to tackle billet parts – especially billet cylinder heads and blocks. “If a shop is just making widgets all day, they could probably get by with the conversational software on the control, but the CAD/Cam system gives you the ability to model the part in CAD and then make a tool path from the model. It eliminates the need for a paper blueprint.

Cowher acknowledges that there are times that it’s faster to program parts conversationally with conversational software on the control. However, he believes that you should be working from models to make tool paths.

Adding to the wishlist of desired features includes a wash-down cycle that keeps the chips flowing away and into a chip auger and out of the way, and an oil skimmer to keep the oil in the swarf skimmed off the coolant, so the coolant isn’t contaminated. Cowher notes that a chip auger or chip conveyor is a must to keep the chips evacuated from the machine, so you don’t have to shovel chips all the time, and there’s less chance of build-up under the way covers, etc.

However, when it comes to spindles, you need to make sure what you’re getting is powerful enough to take care of the operations you do the most. “Everybody looks at the horsepower, but they’re not looking at the torque rating,” says Cowher. “You need torque capability at specific spindle speeds to be able to ‘hog out’ a lot of material in low spindle speed applications, such as for boring out sleeves.” It’s also applicable for high material removal in roughing passes and rigid tapping.

Cowher says Centroid offers a spindle upgrade for a steady diet of billet machining of heads and blocks, or really tough boring and machining applications that will triple the torque. “It’s specific rpms, which is very important on the low end, down around from zero to maybe let’s say 600-800 rpm. Make the range 400-800 rpm if you’re doing big boring operations, or rigid tapping, you have to have lots of torque down there. You don’t need as much torque when you’re 6,000-8,000 rpms and above. Be sure you have a big enough spindle with enough torque to take care of the machining operations you want to do.

Cowher says you don’t need the same amount of torque to skim ports as you do to hog out aluminum with a multipurpose machining center. “Engraving requires almost no torque at all at 16,000-20,000 rpm, so when you buy a machine, it’s important to make sure that the spindle has a suitable torque curve for the applications you do today or plan to do in the future.”

All of these features, Cowher says, except for CTS and the spindle upgrade, are standard in Centroid’s 5-Axis CNC Cylinder Head Porting / Engine Block combination turnkey systems. Other equipment suppliers have many similar features for their machining centers as well. No matter which equipment supplier you work with, it is essential in today’s machine shop to achieve high efficiency while producing precision parts/products. CNC machines with the essential features you need will put you more in control. No more waiting for subcontract work or lost trade secrets from outsourcing.

Rottler’s Ed Kiebler says they have all the fixturing and tooling available to do the standard block and head machining. It is very quick and easy to switch or change between blocks or different operations with their equipment. “Shop owners realize the spindle must be turning to make money, so they think if they buy a bigger machine or a combination machine like a porting/block machining center that they can better justify the cost.

“What I find is that at least 95% of the time customers will buy the combination machine and never use one aspect of the machine and end up purchasing a second specific machine for either porting or block machining. I can’t tell you how many customers have block tooling or fixturing laying around that has never been used because they have so much port work they can’t find time to change the setup, or vice versa where they are so busy machining blocks they have no time for cylinder head porting. They would be much better off buying a combo-machine and concentrating on porting or block machining, and then if they need more work, purchase the tooling and fixturing to accommodate the other operation.”

One thing we know for sure, if you don’t own a CNC machine and are planning to stay in business for years to come, it’s better to be one of the “haves” than the “have-nots.” EB