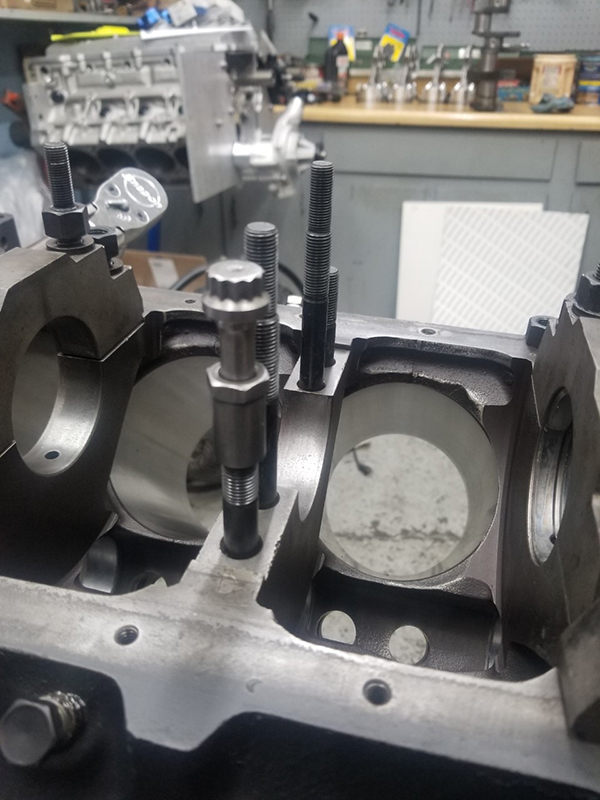

CAP MILLING

I like to mill my main caps instead of grinding them, when possible. The milling process gets them very flat with accurate stock removal. This “vice adjuster” makes it quick to set tilt and I use a precision level along with an indicator to dial-in side to side and tilt before completely tightening the vice. This also works great for setting up other jobs.

Randy Torvinen, Torvinen’s Machine, Manahga, MN

STUD INSTALLER

We use an old roller rocker arm adjuster nut and put a used rod bolt in place of the Allen jam bolt. I use this assembly to install main and head studs when they do not have a hex in them.

Terry Dowker, Dowker Engines, Charlotte, MI

CRANK BALANCE SOCKET

If your shop has a particular crankshaft design you tend to balance on a regular basis, we recommend using a crankshaft snout socket as a locator on your magnetic attachment for rpm and position on your balancer. This allows you to quickly remove cranks and install the transducer very close to center every time.

Adam Cofer, Salina Engine, Salina, KS

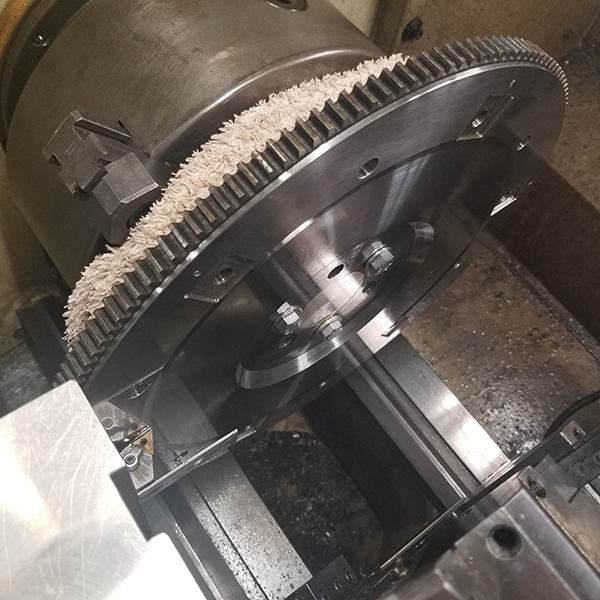

ANTI-VIBRATION TOWEL

When machining or lightening a flywheel on a lathe, vibration and chattering will often cause a poor surface finish. To dampen the vibrations and achieve a nice smooth finish, soak a bath towel in water, wring it out and wrap the damp towel tightly between the lathe chuck and backside of the flywheel. Secure it tightly with a couple bands of safety wire or other suitable method (large plastic zip-ties, shipping strapping, etc). I turned the 14˝ diameter 4140 flywheel shown at 650 rpm resulting in a glass smooth, chatter-free finish, as evidenced by the reflection of the tool insert.

Tom Nichols, Automotive Machine & Supply, Inc, Cleburne, TX

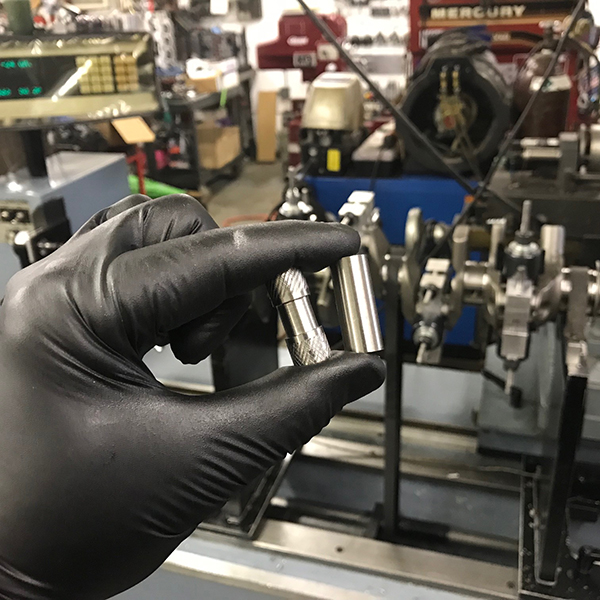

HEAVY METAL

When adding heavy metal to crankshafts, you always want a nice clean installation. I start with a slightly heavier slug than required and machine the center of the tungsten like a barbell to bring the crank into balance, instead of running it short in the hole or drilling the counterweight. This works great to facilitate a “no hole in the bobweight” balance job, if requested. On some pieces, I’ll add some knurling to help hold retaining compound and provide more interference and greater press with the reduced area.

Ron Flood, Cedar Machine, North Branch, MN

MAKE IT BIGGER

Some engines are harder to increase the compression ratio on than others. Sometimes we are limited in cylinder head chamber size and sometimes higher compression pistons are not available or effective for certain engines. Increasing the crankshaft stroke is an often overlooked, but very effective, way to increase the compression ratio and you get a bonus – a displacement increase.

Dave Matton, D and D Auto Machine, Bloomington, MN