Engine of the Week is presented by

Brian Hafliger is a fourth-generation engine builder and owner of IMM Engines in Indio, CA. The 2,200 sq.-ft. engine shop was founded in 1955 by Brian’s great grandfather in the very same building the shop still calls home today. Brian’s great uncle owned IMM Engines next, until Brian’s dad Fred Hafliger took over. Most recently, in 2007, Brian himself took the reins of IMM Engines and operates the shop today along with his dad and a part-time employee.

Of course, Brian’s early engine building influences were aided by his dad Fred and his older family members, but Brian also loved drag racing, motocross and dirt bikes as well.

“I’ve always been around stuff like that,” Hafliger says. “I’m proud to be the fourth generation here. We’re distinctly Mopar, but we do a lot of American V8 stuff. We do big block and small block Chevys, Olds, Fords, cylinder head pointing for import applications as well as side-by-sides – we do a little bit of everything.”

In order to do a ‘little bit of everything’ when it comes to engine work, IMM Engines employs plenty of machine equipment to do as much work in-house as it can, but doesn’t currently have CNC capabilities. Some of those more intricate, specialty jobs get sent out.

“We’re a pretty complete shop,” Hafliger says. “We can do pretty much anything here except crank grinding. We don’t just do race engines either. We do a lot of hobby stuff. A lot of it is street/strip-type stuff, some dirt track, jet boat stuff, marine stuff. It’s all over the board.”

While the family owned and operated shop has been in the same location for 66 years, Brian says they are getting ready to expand into the building next door for additional space.

“The shop is about 2,200 sq.-ft. right now,” he says. “We’re in the process of acquiring the shop next to us and we’re going to split that space, so it’ll be closer to 3,000 sq.-ft. by the end of the year.”

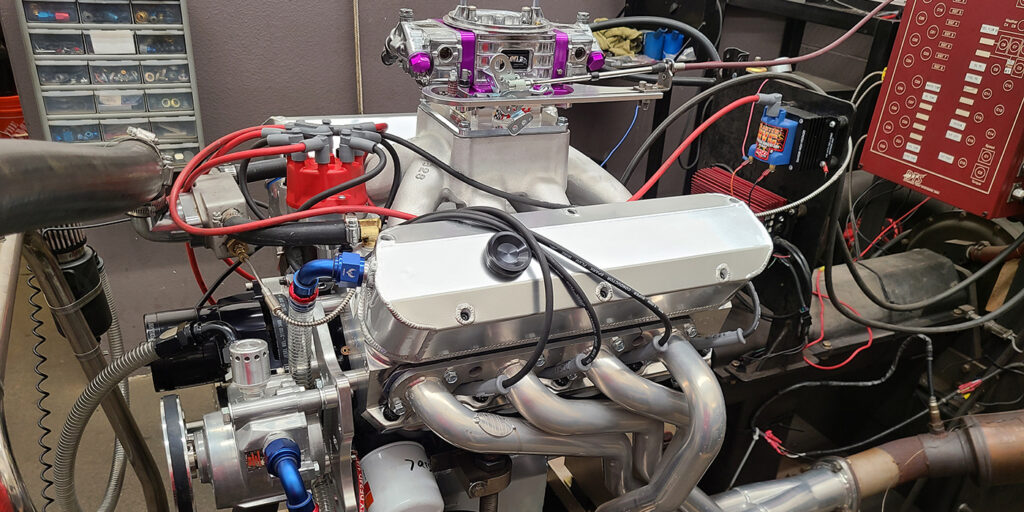

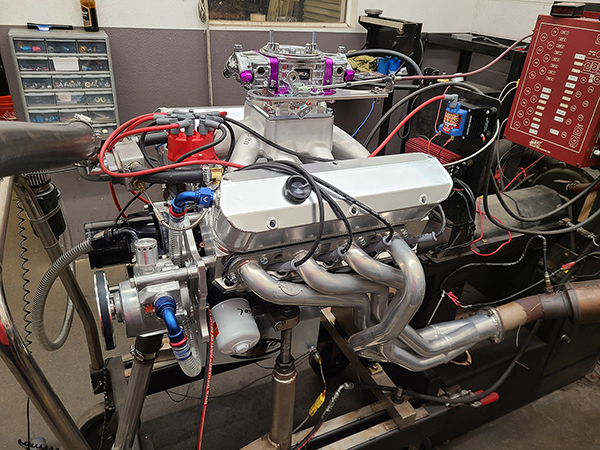

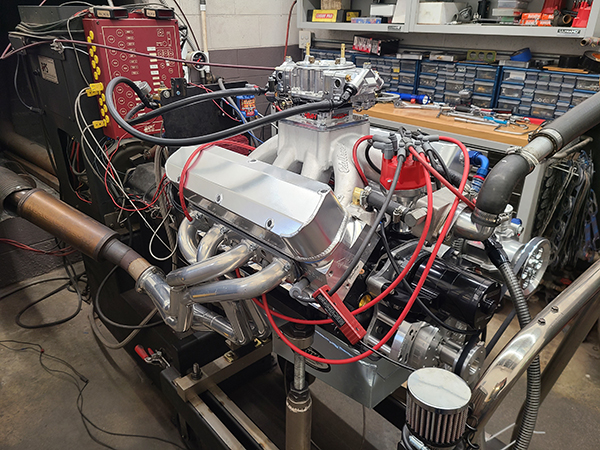

One piece of equipment Brian is especially proud of is the shop’s 2,500-horsepower capable DTS Powermark engine dyno, which he purchased around the time he became owner. It has proved to be a valuable addition.

“We do our own in-house dyno testing and dyno sessions,” he says. “We dyno every engine that we build and sell, and we can pretty much run just about anything on it, within reason. Ninety percent of our engines are anywhere from 400 horsepower to 1,200 horsepower.”

A perfect example of an engine that fits those parameters is a build IMM Engines just finished for a customer with a ‘65 Ford Falcon bracket car. The customer wanted to run 5-second 1/8th-mile times and was adamant about using 1.750˝ headers he already had. With this in mind, Brian got to work building a 427 small block Ford nitrous engine.

“The customer had a little bracket car and frequents Irwindale and Barona race tracks,” Hafliger says. “We were asked to make 650 horsepower, but one obstacle of the build was we had to work around existing headers. The guy was insistent that he wasn’t having headers made. It was kind of a small 1.750˝ header that was built for his ‘65 Falcon. It’s a real, real tight engine compartment, so we basically built the engine around the header, which I do not like to do, but the customer is always right. They’re the ones with the money.”

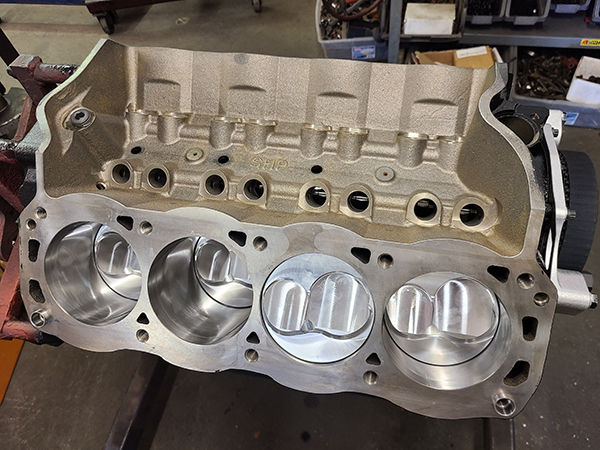

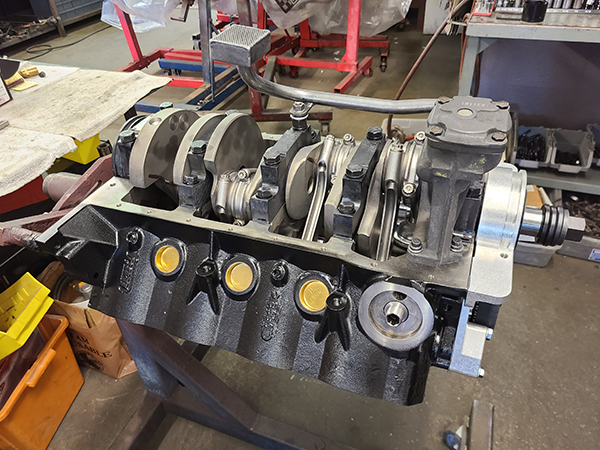

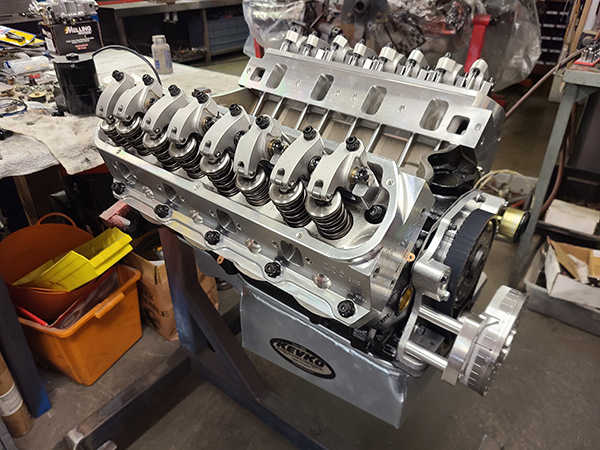

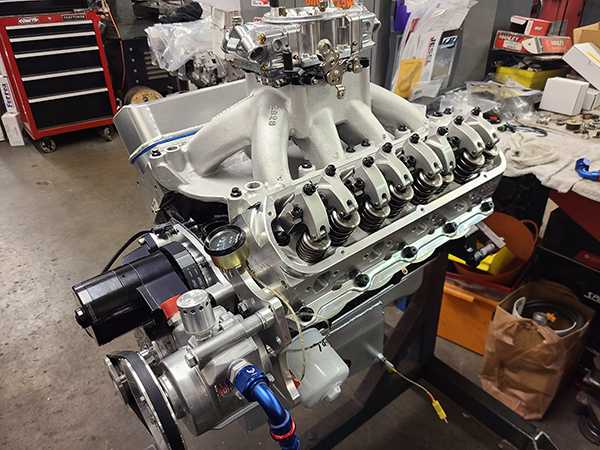

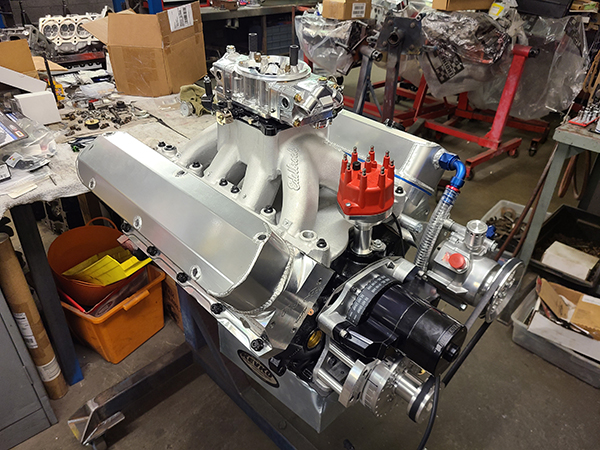

Despite the handcuff created by the small headers, the build features quality components. It started with a Dart SHP block built out to 427 cubic inches, Scat internals, CP pistons, and Trick Flow cylinder heads.

“We built it 427 cubes and I kept the compression down because there’s only four bolts per cylinder on the Fords,” he says. “We used a Scat 4340 crank with a 4.000˝ stroke that was internally balanced, as well as Scat H-beam rods with ARP 2000 bolts. Most of the Scat stuff will handle 1,200 horsepower and we’re below that. I’ve used their stuff a lot and I’ve never had a problem with it.

“The custom CP piston was their full concave piston for the nitrous because it softens it up. There are different approaches to that. I know chamber softening is kind of a big hit nowadays, but honestly, if you’re designing the piston, you can do a full dish and get the same effect if you’re not looking for every ounce of power. It saves money and a bunch of time.”

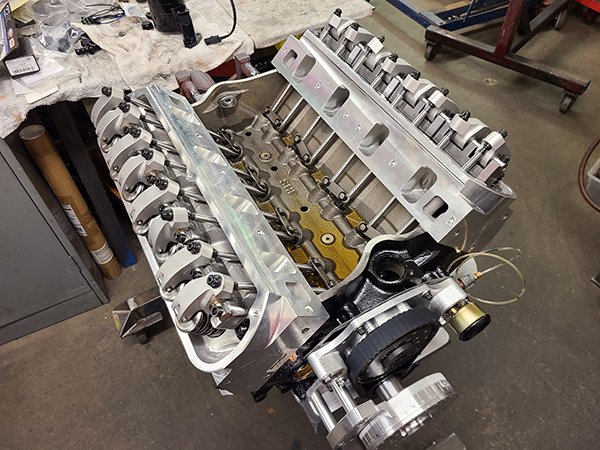

Brian opted for Trick Flow’s 11R 205 cylinder head because it puts the exhaust port location in the stock location, and this engine originally was built around a stock 351 Windsor with Edelbrock heads, so he kept that theme.

“We had to modify these heads because they don’t come with 11/32nds valves,” Hafliger says. “They come with 8mm and nobody really makes a long 8mm valve. We ended up having to change the guides out and go 11/32nds on the exhaust and 5/16ths on the intake to get the length that we needed for the Ferrea valves.

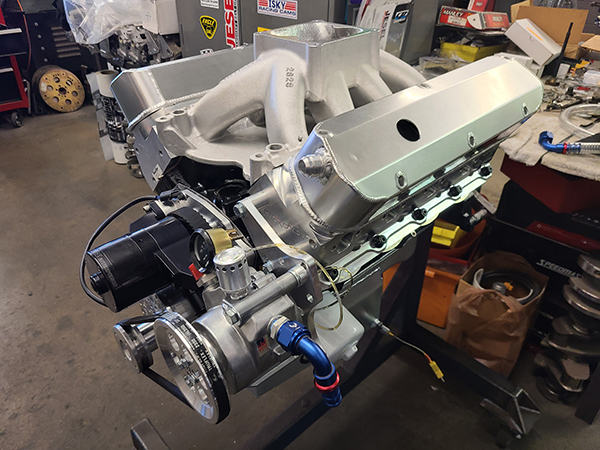

“We also used a Jesel belt drive on it and Jesel rockers for these heads. After we changed the guides, we touched up the valve job, but we didn’t do any performance porting or anything like that on the heads. They were run pretty much as they come. We didn’t get too trick and custom with head gaskets and o-rings and stuff like that, either. We just used an MLS-style gasket and let the nitrous do the work.”

For camshafts, IMM Engines uses custom grinds either by COMP Cams or Isky. This particular grind came from COMP. It’s one of their new, low-shock lobe families that Billy Godbold designed.

“We did that set up to keep it smooth and friendly,” he says. “We went solid roller basically because the low-shock stuff and the BAM bushed lifters will go forever if you lash them once in a while. The set up was built for .700˝ lift. We used a 1.7 rocker ratio.

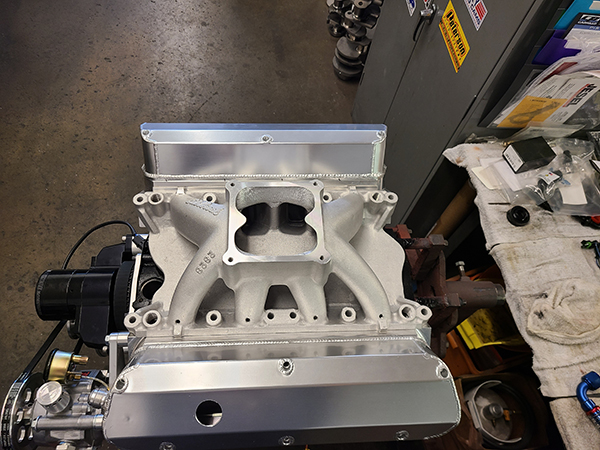

“The intake was an Edelbrock 2828, which is their NASCAR-style intake. We went with that solely to get more plenum volume. Even though it’s a direct port nitrous setup, I still wanted more plenum volume because everything still gets blown up into the plenum, so the bigger the plenum generally the better the fuel distribution, even with direct port, so we went with that intake. We also went with a Mark Whitener full billet 4150 carburetor that’s 1050 cfm.”

The small block Ford also got equipped with King bearings, coated cam bearings, a Melling Select oil pump, and a custom KEVKO oil pan.

“This engine wasn’t anything real, real crazy, but we made almost 700 horsepower N/A with just 13:1 compression and a small solid roller cam,” Hafliger says. “It was a pretty cool piece. The customer is going to put about 350 to 400 horse of nitrous to it, so it’ll be roughly a 1,000-horsepower engine. I was happy with the power.”

With the engine finished up, the customer is finalizing the car’s wiring and hopefully he’ll be getting the Falcon and it’s new small block Ford engine to the track very soon.

“Being a ‘65 Falcon, it should be pretty light, so we expect it’ll be capable of 6.20s or better on the motor,” Hafliger says. “With the nitrous, he should be well into the 5s, maybe low 5s.”

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].