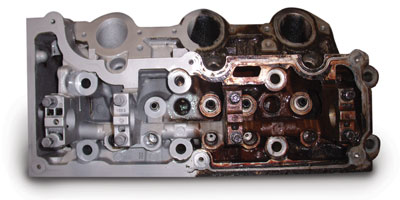

Polymer coatings in the engine performance industry have become extremely popular in the past 5 years. The usage of polymer coatings has been widespread, not only in engine bearings, but also in pistons, cylinder heads, bolts, and other engine parts operating in heated and pressured environments.

King Engine Bearings has been at the forefront of polymer coating technology, with research and development efforts led by Dr. Dmitri Kopeliovich to expand its range of polymer-coated materials. The result was creating various solutions for different types of challenges, each tailored to suit unique engine characteristics.

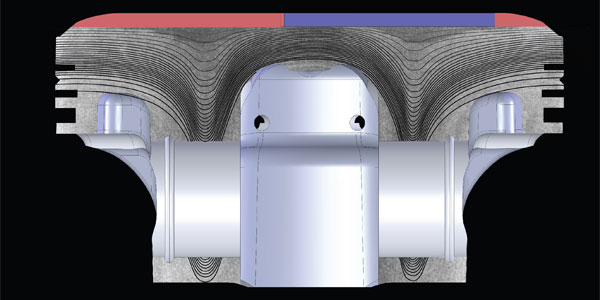

Polymer coatings were developed to protect bearings from seizure caused by oil starvation and metal-to-metal contact. Various friction and wear conditions dictate the need for different approaches. MC Bearings were developed to deal with metal-to metal contact in Start/Stop engines. Those require a wear resistant coating that will stand up to the conditions due to the nature of the operation in such an engine. MC engine bearings are an example of a polymer coating invented to address this specific problem. The MC polymer coating was designed specifically to be applied over bi-metal strengthened aluminum as part of the bearing manufacturing process and serves as the extra protection layer.

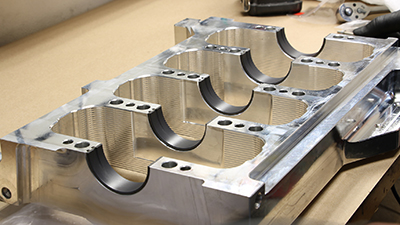

In the racing and high-performance world, there are many engines with vigorous demands that develop loads above 15,000 psi. King established the GPC series bearings to address this kind of extreme load. GPC bearings are made for Sprint Car, Diesel Performance and various European engines, such as BMW’s S65, S85, S63 and other applications. It consists of lead-bronze layer over steel, a silver matrix overlay containing solid lubricant particles, and coated with a polymer coating.

King’s prominent and biggest range leader is the XPC series with pMaxKote™ polymer composite. It has become the industry leader and desired by performance engine builders and race enthusiasts. pMaxKote is specially designed to be applied over the XP series tri-metal structure without changing the bearing’s original wall thickness. You can find XPC in almost all of King’s range.

King has just recently introduced its newest polymer coated bearings called the TFC series. The TFC series bearings are suited for top fuel and pro mod drag racing applications where horsepower ranges from 3,000 to 10,000. The polymer coating helps bearings survive when extreme loading squeezes out the oil film.

All polymer coatings developed by King are factory applied and are formulated to be applied over various existing bearing materials such as MC Aluminum, XPC Babbitt, GPC Silver matrix and TFC Babbitt bearings.

This ongoing R&D and manufacturing effort at King Bearings continues to yield more reliable engine bearings for all types of applications, resulting in reduced wear and longer life.

This article was sponsored by King Engine Bearings. To learn more, please visit our website at www.kingracebearings.com.