Engine of the Week is presented by

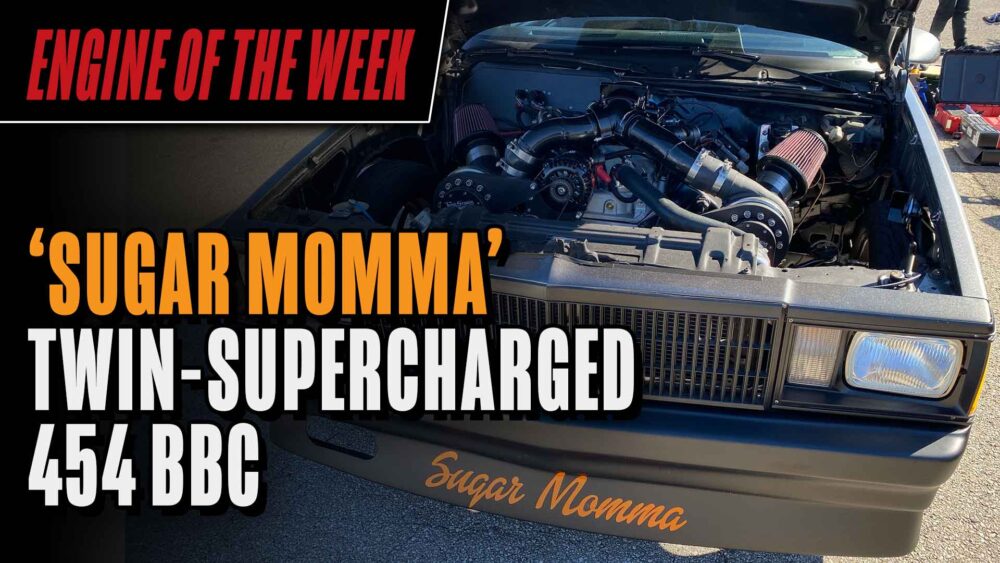

One thing we missed about not having a live PRI Show in 2020 was seeing the engine build for the annual Sunnen Charity Engine Sweepstakes. As a way of reminiscing, we’re going to give you a glimpse at the 2017 Sunnen Charity Engine Sweepstakes build – a 454 cubic inch ProCharged LSX engine done by Patterson-Elite Performance. It’s our latest Engine of the Week.

This 454 cubic inch ProCharged LSX engine was the second time Sunnen called on Patterson-Elite Performance, located in Augusta, KS, to build an engine for PRI. The proceeds from all ticket sales have benefited Victory Junction, a charity that makes a difference in the lives of children with serious illness.

In 2016, Patterson-Elite’s engine build brought in more than $40,000. They wanted to build an engine that would top that number.

Midway through the design process, the idea to put a supercharger on the LSX engine came about. Procharger, located in Lenexa, KS, is just 100 miles from Patterson-Elite’s shop, so it was a no brainer for them to help out.

Other parts of the LSX build include: ARP bolts and fasteners; an ATI harmonic damper and flexplate; CP-Carrillo pistons; Clevite rod and main bearings; a COMP Cams camshaft, timing chain and front cover; a Holley intake manifold, ECU, injectors and throttle body; Jesel valvetrain, rocker arms and roller lifters; Manley spring locators; a Melling oil pump; a Mezere water pump; a Moroso oil pan; PAC retainers and locks; Pertronix coils and wires; a Procharger F1-X supercharger kit; PSI valve springs; Trend pushrods; and a billet crankshaft.

All the help was much appreciated, but that didn’t mean the build went without a few issues needing to be resolved. Here’s shop foreman Cory Mattson to tell you more.

“One of the issues that we’ve seen with the supercharged engines on our COPO program is the need for a Torrington thrust bearing. That’s one of the things we did that’s not a common deal for everybody else. We put a Torrington thrust bearing on the front of the crankshaft to alleviate the stress on the babbit bearing, and we had to do the same thing on this motor to alleviate or try to nip any problems that might arise in the bud before they actually became a problem.”

With the 4.125˝ stroke, the shop also had to adjust clearances to make sure they cleared the rod bolts and that the skirts of the pistons cleared the counterweights of the crankshaft.

“One of the other things we did with the Jesel rocker arm system, since we changed from a pedestal mount rocker arm to a shaft mount rocker arm, it required some machining on the cylinder head,” he says. “We basically removed the stock pedestals and created a flat surface for the Jesel rocker bar to mount to and then bolted that and machined all that to adapt the rocker bar to the LSX head.”

The block had work done to it as well. Patterson-Elite bored it to 4.185˝, squared the decks to a height of 9.240˝ and honed it on a Sunnen SV-20 Diamond hone.

“We used ARP main studs and ARP fasteners in it. We flat milled the heads to get the compression ratio to the point that we wanted it at about 10.5:1. We also had to do some minor pushrod clearancing on the cylinder heads.”

Once all the work was done, the LSX got put on the dyno before being shipped to Indianapolis for display.

“When we put it on there we were very surprised. We were hoping for around 1,200 horsepower at around 7,000 rpm. On the first pull it made 1,322 horsepower and 1,050 ft.-lbs. of torque at 6,500 rpm. That put a halt to the RPM that I could dyno the thing to. I couldn’t go to 7,200 rpm because we were making 22 lbs. of boost at 6,500 rpm and the combination wasn’t built for 22 lbs. of boost. So what I had to do was back the RPM down and get the tune-up as good as I could.”

Mattson also said that the shop plans to change the pulley so that it will have about 16 to 17 lbs. of boost at 7,000 rpm, and is adding an intercooler to the system to help it make even more power.

What made this engine really special, however, was the F1-X supercharger kit from ProCharger. It was the first time Patterson-Elite Performance used one on one of its engines.

“We’re really impressed with the Procharger. Our supercharger experience is basically with the COPOs and the Whipple that they have on those. The Procharger has tremendous capabilities and we’re excited to do something else in the future as far as building another Procharged motor for drag racing in NHRA.”

Since this 454 cid Procharged LSX wasn’t built for a specific class, the engine could be used for a number of applications. It could even be a 1,300 hp street engine.

“We just wanted to build a cool combination that helped us learn some new technologies at the same time. The idea was to help out a great cause and think outside the box a little bit for our program. Everybody in here is pretty much a naturally aspirated guy working on NHRA, Stock and Super Stock, Comp Eliminator and some Circle Track stuff. This engine let us play around with some technology that we don’t get to see very often.”

At the end of the 2017 PRI Show, Sunnen’s Charity Engine Sweepstakes once again raised tens of thousands of dollars for Victory Junction. The lucky name drawn from the ticket barrel was Ryan Anderson of Monster Jam fame. When the dust settled, this build raised $50,000 for Victory Junction.

“Every one of us here at the shop has kids. It means a lot to us to be able to help out a charity that helps kids in a time of need. That’s something we’re all on board with here.”

And all of us at Engine Builder couldn’t agree more.

Engine of the Week is sponsored by PennGrade, Scat Crankshafts and Elring. If you have an engine you’d like to see featured, please email Editor Greg Jones at [email protected]. Thanks for watching!