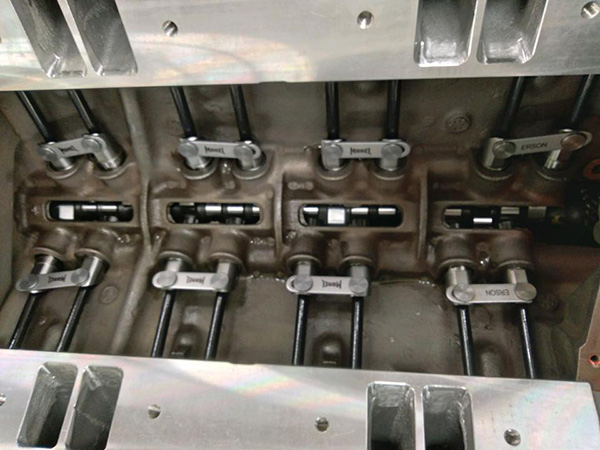

PRIME WITHOUT THE INTAKE MANIFOLD ON

I always prime all of my engines with the intake manifold off and the valley open. You can see oil escaping around lifters and cam bearings. You can see if you have the wrong base circle camshaft on SB Ford hydraulic roller cams and if the lifter bands are poking out of the block. You can see rotating lifters or if they are sticking. This has saved me several times. It has saved many cams, saved lots of hours in dyno time, saved me from removing and reinstalling manifolds, and in comebacks.

Randy Quam, Competition Engines, Eagan, MN

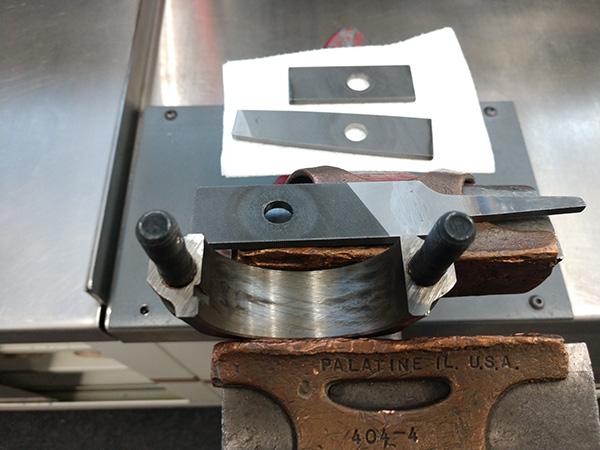

BROACHING THE SUBJECT

When broaching a keyway in a relatively thin part, such as this modified gear cut from a Chevy camshaft or a narrow pulley, I use an aluminum spacer to hold the broach guide bushing up and out of the work piece. This will help hold the broach straighter as it enters the work piece.

Tom Nichols, Automotive Machine & Supply, Inc, Cleburne, TX

EASY ROD DEBURR

I have an easy way to deburr a connecting rod with the bolt still in and even performance rods with the dowels in. I had some file pieces drilled by my buddy at a tool shop. He drilled them about .005˝ over with carbide drills. I have 3/8˝, 7/16˝ and 1/2˝ sizes done, and that will cover most rods. I just give them a few twists to knock off the dings and high spots.

Randy Torvinen, Torvinen’s Machine Shop, Menahga, MN

SUCK IT UP

When performing volume checks, this cuts down on the mess to clean up afterwards. Once finished pouring the volume, we use this syringe and a piece of tubing to suck the fluid out of the cylinder or chamber before removing the plate. The syringes can be found at most farm stores, as they are commonly used by veterinarians.

Adam Cofer, Salina Engine, Salina, KS

SEAT REPAIRS THAT DON’T LEAK

When installing valve seats, you sometimes run across porosity that leads into water at the base of the counterbore. I like to pressure test after the counterbores are machined to be sure, if there is a question.

If you have a seat that you’re trying to seal up, you can make a positive chemical bond barrier by machining the O.D. of the seat for a small groove. This allows the retaining compound or sealer of your choice to have a positive contact all the way around the diameter above the leak. Just coat the seat and make sure that when you drive it in that it is liberally coated around the O.D. As a bonus sealing measure on a seat with porosity in the counterbore, I’ll drill and tap a hole in the backside of the head directly above the compromised area as an access hole. Then, I get in and media blast the area, lay down some fluid weld or epoxy and let it dry. You can air dry, heat gun or oven cure. I plug the hole with a pipe plug. I’ve never had one leak after this repair.

Ron Flood, Cedar Machine, North Branch, MN