While some people seem to think internal combustion engines (ICE) are losing favor to electric powertrains, that’s far from reality. The ICE is alive and well, especially in view of many new developments underway. As a prime example, Speed of Air (SOA) Engine Technologies has found a way to optimize combustion that delivers several startling performance benefits. A significant increase in power is just one among many. In addition, SOA treatments reduce emissions and fuel consumption, along with increasing engine life and fewer service intervals.

Normally, even one of these improvements would be welcome, but integrating all of them together is a remarkable achievement. Notably, SOA’s technology applies to virtually every type of consumer and industrial engine—and all types of fuel.

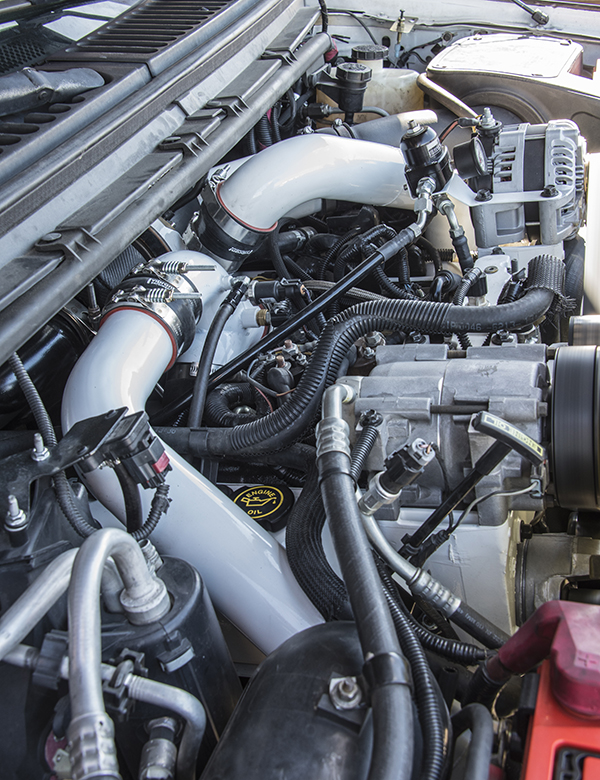

As examples, we’ll be focusing on diesel engines in particular, as we were able to test a couple different domestic pickups equipped with SOA engine technologies. At first glance, SOA’s patented technology appears to consist of solely a textured or dimpled surface on the piston head. This treatment can be applied as well to the intake manifold and turbocharger compressor blades (if so equipped). Similar to those found on a golf ball for improved aerodynamics, these indentations are both complex and varied in size and shape.

Even though a dimpled golf ball has less drag than a smooth one, on a piston head the effect is somewhat different. It actually creates a slight adhesion for the flame front, slowing it for a longer burn time. Another benefit is to even out the rough, jagged edge of the flame front that is otherwise unstable and extinguishes too early. The reason for doing so is a key element of how SOA technology enhances an ICE.

“This instability contributes to elevated emissions, higher fuel consumption and less power,” explains Joe Malfa, technical director for Speed of Air. “With SOA’s technology, the flame front can stay uniform and active for a longer period, allowing for improvement in the combustion process.”

In addition, SOA’s technology includes a proprietary combination of specialized metal coatings. These coatings are used to control combustion chamber temperatures that enhance flame-front travel. Why so?

“The purpose of the thermal control benefits is to limit the thermal growth of the piston and retain heat in the combustion chamber,” Malfa says. “Heat is power, and when it is absorbed into the heads, block and piston, that power is not being harnessed from the engine.”

Taken all together, these SOA treatments create a boundary layer that greatly enhances the flow of the air-fuel mixture and flame front within the combustion chamber walls. As a result, this layer becomes thinner and more turbulent, with the flame front moving closer to the walls. The result is markedly better combustion and far fewer carbon (soot) deposits, minimizing a common problem for diesels in particular. All told, the differences from a conventional ICE are dramatic.

Putting them in perspective, Chris Parkhurst, SOA’s managing director, characterizes the overall significance of these performance gains this way: “We have developed a disruptive and peerless engine technology that enables internal combustion engines to operate with better fuel efficiency, better performance and with substantially reduced emissions.”

As proof, a dyno test on an ’02 Ford with a 7.3L Powerstroke revealed some startling numbers. In stock form, this engine with a manual transmission typically delivers a peak rating of 275 hp at 2,800 rpm and 525 lb./ft. of torque at 1,600 rpm.

While 7.3L are known more for long-term reliability than high-performance potential, this engine is capable of far more power when treated with SOA technology. The power maxed out at more than 565 hp and 1,304 lb./ft. of torque.

Testing was performed on a SuperFlow chassis dyno at the Truckee Meadows Technology Center in Reno, NV by Tim Anderson of T&A Performance. He had recently completed a two-year restoration of the truck, which included stripping the engine block clean for a rebuild. The cylinder heads were reconditioned by Robert Rubalcava of DEMT (Diesel Engine Machine Technologies) in Belgrade, MT, to stock specifications.

In addition to installing SOA-modified pistons, Anderson used a mild camshaft, and a single Garrett T4 turbocharger with a turbine speed sensor and Turbosmart HyperGate45 wastegate. He also upgraded the injectors from 120 to 238cc, single-shot, 80%-over nozzles. The exhaust manifolds and turbine housings were modified and coated with a thermal barrier and heat dispersants from SOA as well.

Anderson notes that similar power numbers can be achieved with changes to the cam and increasing the injector size, but not without generating significant amounts of black smoke. This is obviously undesirable, since it not only increases exhaust opacity, but also represents unburnt fuel and lost power.

In contrast, SOA’s treatments achieve these numbers without this obvious drawback. Malfa notes that, “The test results show the engine runs very clean with an opacity average of 4.41 percent, oxygen average of 16.77 and CO2 average of 2.42 percent. NOx average is 360.33 ppm.”

These numbers were accomplished without the use of any emission equipment, such as EGR, DPF, DOC, and the exhaust from the tailpipe was not scrubbed by any after gas treatment. The truck was also tested for opacity and averaged 12 percent under heavily loaded conditions and less than 5 percent under normal highway speeds. These opacity results would pass California’s requirements for a 2007-or-later truck equipped with after-gas devices.

Anderson points out, too, that these improvements come without having to fly-cut or “de-lip” the bowl in the piston head, which can result in cracking. Engine noise is also noticeably reduced.

How about fuel consumption? Note that the truck was fitted with a five-stage tuner in order to see the difference in the engine response when adding fuel, and to test the impact of the SOA technology on emissions and tailpipe opacity. The tuner was dialed up after each three-minute engine load test on the dyno, along with the emissions and tailpipe opacity calibration.

The purpose of this test was aimed at simulating pulling a 30,000-lb. trailer load at 50 mph instead of the more common test with maximum hp or torque. The chassis dynamometer was set up to hold the vehicle at 50 mph, wide-open throttle at full load. The engine revs were limited to 2,500 rpm. In order to avoid damage to the dyno, the engine was not run at full power during the full sequence of tests, which lasted for almost one hour.

Extensive testing indicates that on average, an F250 Ford Super Duty typically gets a combined fuel consumption (both street and highway) of 13 mpg. Anderson’s truck achieved 22 to 24 mpg at freeway speeds. A Ford F350, also fitted with SOA components and coatings, reported as much as 24 mpg or even more.

While fuel savings from SOA technology will vary with engine type and application, consumption has been reduced in general by as much as 30 percent in constant-speed conditions. Clearly, in commercial applications, SOA can help businesses not only reduce fuel expenses, but also avoid costly EPA fines and the extra expense of meeting emission requirements with after-gas modifications or re-powering.

As for improved engine life and reduced service intervals, Anderson’s newly built truck will need time to validate these benefits, but other SOA engines indicate surprisingly cleaner components after many miles of service. For example, in a CAT 3516 mine haul truck engine, oil-change intervals could be extended by nearly double that of a conventional engine. Based on oil samples from the SOA engine versus the stock engine, SOA reduced the soot levels in the oil by 55 percent over a period of 27 months.

The economic impact of this aspect alone saved nearly $250K in operating expenses over 18,000 hours of service life. That figure is based solely on labor and materials for oil changes, not including maintenance or repairs due to engine wear, or lost production due to service down time.

While SOA’s innovations are relatively new to the engine market, they have been in development for a couple decades. Initially applied to V-Twin motorcycle engines, this patented technology is now benefiting much larger and more complex powerplants, backed by years of independent testing. All told, SOA has a proven technology with real-world, cost-effective benefits. It shows that the internal combustion engine can still be a viable, long-term option in a rapidly changing world.