Whether it’s an OEM engine or a performance-built engine, the use of power adders continues to be a popular choice. Turbocharging, supercharging and nitrous are the primary options for adding power to your engine, and in a majority of builds and applications, turbochargers and superchargers are what people rely on most. You might be wondering why go with one over the other and what makes them different?.

Both superchargers and turbochargers serve as a replacement for displacement and help force more air into the engine. With a turbo, you’re using the heat energy from the engine’s exhaust. A supercharger is driven off the engine’s crankshaft. Turbochargers capitalize on ‘free’ energy that would otherwise be lost through the exhaust.

Driving the turbo does increase exhaust backpressure, which puts some load on the engine, but the net loss tends to be less when compared to the direct mechanical load that driving a supercharger involves. What most people notice is that superchargers can provide their boost almost instantly, whereas turbochargers typically suffer some lag to build pressure.

Obviously, in certain applications, wasting valuable time waiting for exhaust pressure to build isn’t an option, so a supercharger is employed. In other instances, folks can’t afford to lose horsepower, so a turbo is a better option.

No matter how you choose to add boost to your engine, both superchargers and turbochargers can be great options depending on your engine and application, but we want to spend some time talking superchargers.

Supercharger Styles

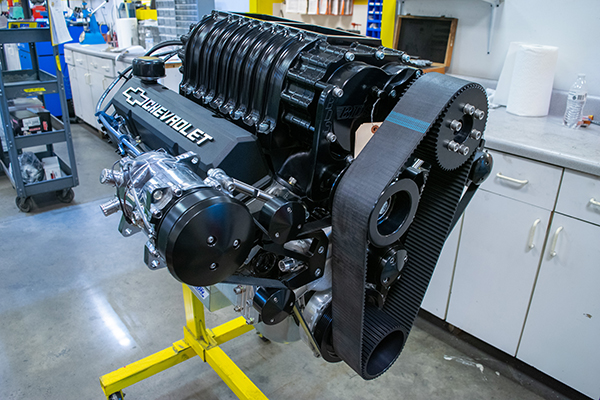

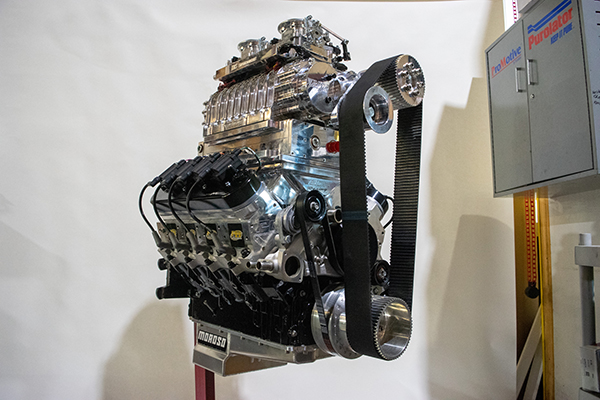

Superchargers have been in the market for a long time and there is a large variety to choose from to suit every need, car and budget. Your basic Roots supercharger is usually installed right where the intake manifold is. It uses spinning mesh lobes that throw air from one end to the other and the pressure builds up inside the intake manifold, letting in a gush of air in bursts.

A twin-screw supercharger whirls and draws in the air in a corkscrew fashion. The air is compressed and then forced into the engine this way.

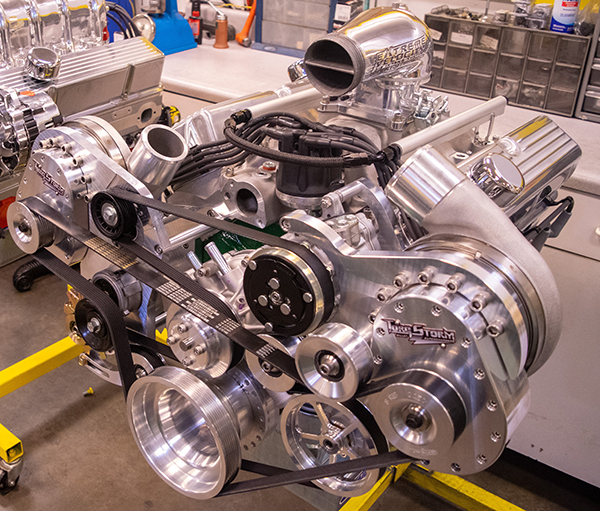

Then, you have centrifugal superchargers that use an impeller that distributes air by a strong centrifugal force where a diffuser turns the air into high pressure. Brands such as ProCharger, Vortech and TorqStorm are examples of this style of supercharger. Centrifugal superchargers force air into the engine in a consistent stream rather than bursts.

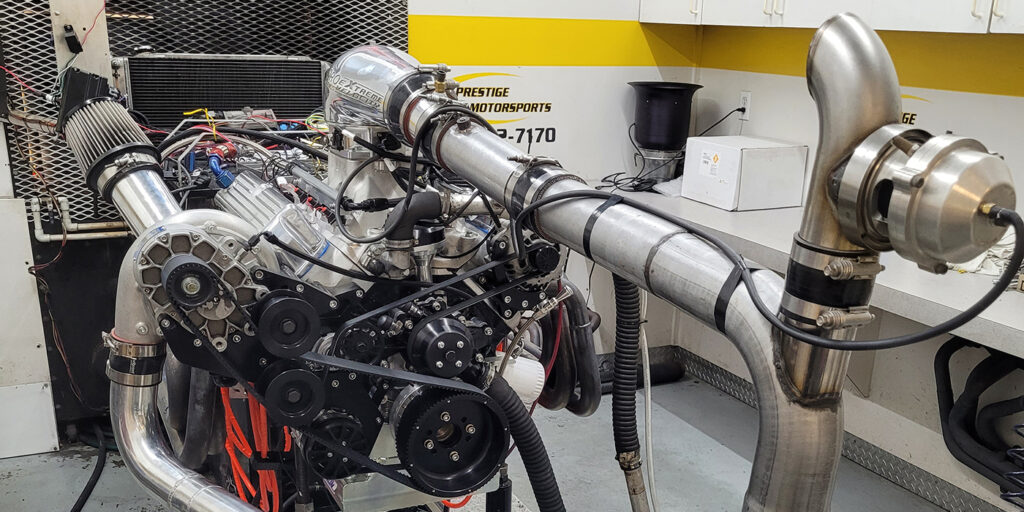

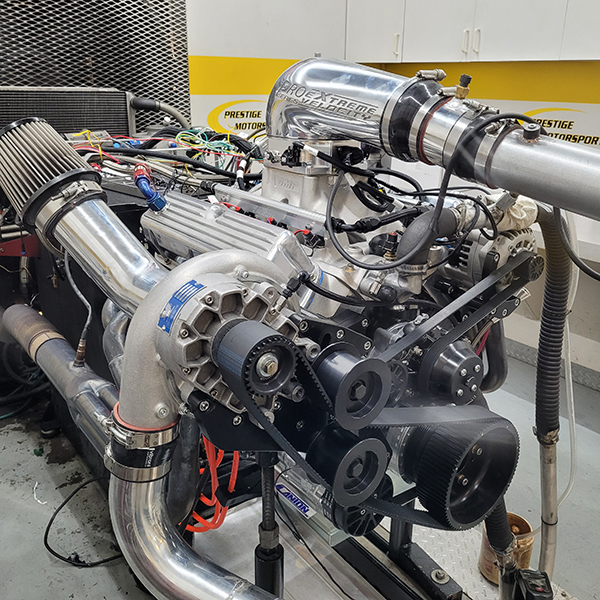

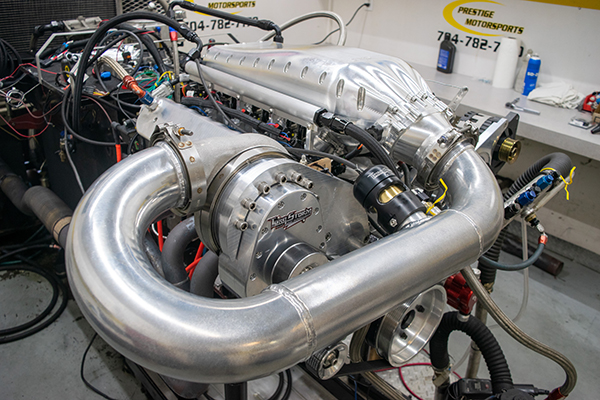

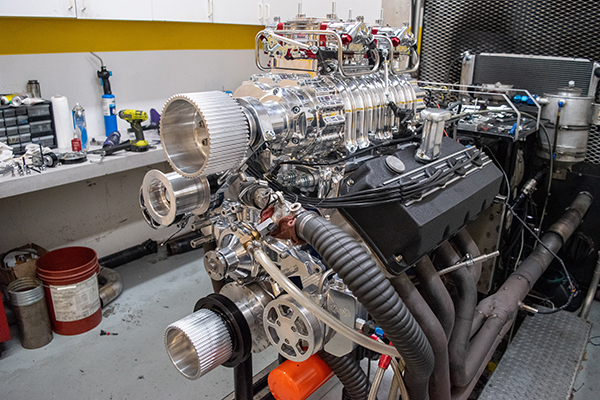

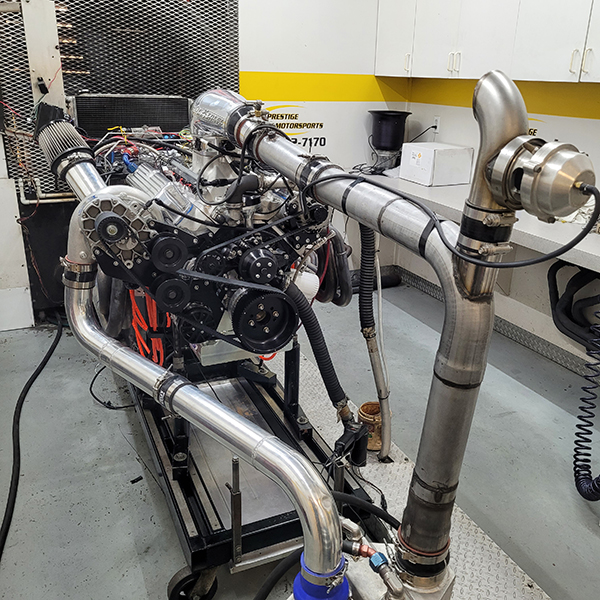

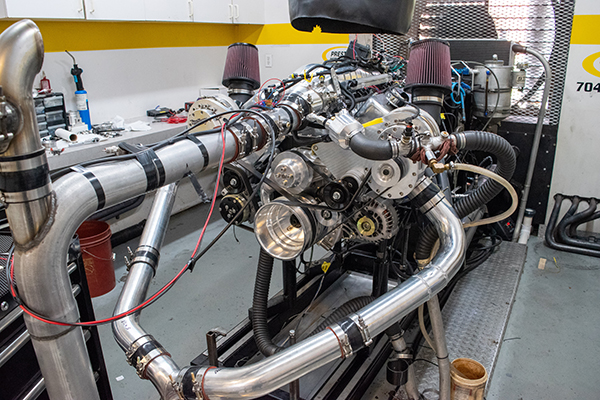

“We’ve worked with all kinds of supercharger brands and companies,” says Doug Aitken, owner of Prestige Motorsports in Concord, NC. “We use a lot of side slingers or your centrifugal superchargers such as TorqStorm, Vortech and ProCharger. We’ve also dibbled and dabbled with your screw-style superchargers such as Magnuson, Whipple and Kenne Bell, as well as your older Roots-style like Blower Shop or BDS.”

Pros and Cons of Superchargers

When it comes to superchargers, clearly there are a lot of options. These days, the customer usually has a desire to use a certain style of supercharger or might have a brand loyalty.

“If a customer asks me, what should I use? It just comes down to what the expectations are,” Aitken says. “We focus on accessory drives. Are they running AC or power steering? Do they want the power right now or to come in gradually depending on how the rest of the car is built? Or, is it a drag piece? Those are the main things, but a lot of times I think it’s just the customer saying what he wants and we give him pros and cons depending on what the rest of the car entails.”

As with anything to do with engine building, the pros and cons depends on the customer and their expectations and application.

“With a turbo, you’ve got all this plumbing,” Aitken says. “You’ve got your hot side and cold side and a lot of stuff going on, which not only costs money, but adds complexity to the system. Whereas with a supercharger, it’s going to retain all the accessories as well and you just bolt the blower on. It doesn’t really disturb too much and you don’t have a whole bunch of extra piping complexity.

“But, when you get into certain combinations like an F3 ProCharger, which is a drag race deal, and maybe the customer is going to street drive it and wants AC, there’s really nothing out there for a front drive system. You have to make that stuff. A lot of customers want to be able to have their cake and eat it too, and it depends on what they’re doing and what their budget is. The reason we do so many different superchargers is mainly based on consumer demand.”

One downside to superchargers is in order to increase or decrease the amount of boost and power output going to the engine, you have to mechanically change pulley options.

“The nice thing with turbochargers over any supercharger is you’re using a wastegate to control your boost.” he says. “That’s nice because you don’t have to mechanically work on changing pulley options and stuff like that. That’s a drawback to superchargers.

“However, if it was strictly a drag piece, I would go with a crank-driven ProCharger or a TorqStorm. Not only does it come with the entire front accessory drive system, but if you want 1,000 horsepower or so, TorqStorm has dual superchargers. That has less load on the crank and they’re running serpentine belts, so you don’t chunk belts all the time.

“The problem you run into with a lot of your side slinger stuff, whether it be a Vortech or a ProCharger, is in order to make that same power on a single blower, generally speaking, you’re running a cog belt, which just don’t last. If it’s a street car, it’s not conducive to high durability over a long period of time.”

However, there are crank drives available with gear sets where you’re not even running a belt, so that takes the durability factor away. You don’t have to worry about that with the gear drives and you very rarely see them fail.

“If it’s an F3 or F4 for a full race application that’s crank driven with a quick-change gear set, that’s definitely the ticket,” Aitken says. “And Vortech also has an offering for that kind of application.”

In the street market, twin-screw superchargers and Roots blowers are great options depending on what the customer wants, if it fits under the hood and if he wants his power right now versus one that builds boost with rpm.

“With the Whipple superchargers there’s a lot of front drive accessories designed around those, so all of your accessories are included,” he says. “The Whipples are nice for the guy who wants the power right now, and maybe they like that Whipple whine. There is a drawback based on trying to keep it under the hood, depending on what it’s going in. That’s also where ProCharger, Vortech and TorqStorm really shine because you’re able to keep those superchargers underneath the hood. They’re smaller and lightweight and are attached to the engine as opposed to the intake manifold.

“In comparing superchargers, the screw style has lobes and rotors that are heavy. The heavier that stuff is the more drag on the motor. You obviously aren’t going to net as much as if it was turbocharged. A lot of people get hung up on the fact that superchargers cost you horsepower.”

The fact is, every supercharger company has excellent offerings and sometimes it just comes down to favoring one brand over another. However, the application, the budget and the space available under the hood, should be the driving factors for your supercharger decision.

Horsepower Gains

When it comes to boost and supercharging, there’s a huge misconception nobody really talks about. When you hang a blower on the side of an engine, the limitation of the motor making power, assuming it’s got all good parts, is all reliant on the blower itself. It is the primary air pump and it can only move so much air.

“A YSI blower can move X amount of air, so if I put that on a 427 or I put it on a 363, the peak power will be the same,” Aitken says. “No matter what camshaft you’ve got in there, it will be the same. The only difference is at what level of boost it makes that power at. The 427 is a larger motor, so that gobbles up the air and might make 1,100 hp at 12-lbs. of boost. Whereas the 363 would make the same power at 16-lbs. The boost is a measurement of restriction. Some may argue that you need to spin the blower harder. Well, if you’re already at max blower speed, you’re done. We’ve proven that over and over.

“It’s a little different in your turbocharged world, but in superchargers, you’re limited by the size of the blower itself. We’ve done quite a bit of work with TorqStorm and their twin superchargers on three totally different engines. We had a 540 big block, a 427 Ford and a 427 LS. Those engines are totally different architectures, valve angles, valve sizes, manifold arrangement – everything is different. They all made within 1% of power of each other.”

There’s a lot of stuff surrounding power adders such as superchargers and turbochargers that people don’t fully understand. One of the biggest examples is that bigger is not always better.

“Sometimes technology exceeds the bigger is better theory,” Aitken says. “What I mean by that is Whipple has a 4L and a 4.5L supercharger that will net you somewhere in the 1,100 horsepower range. They’ve also got a brand new 3L and it’ll make 1,100 hp. You have to ask the question, why would I buy a 4.5L blower when a 3L will make the same power? It may be an application thing.

“The 4L is a rear feed, so in a sand car, the motor is turned around and they’re sucking air from the front of the vehicle. They don’t want to be sucking up the sand. That would be a reason why you would use that blower. But, if it’s in any kind of street car, I’d be using the 3L or their new 3.8L over any 4L or 4.5L, because they make more power.

“There’s new technology in there – the rotor design, rotor material and air entry is all different. The technology has surpassed the supercharger just being larger. We can make just as much power in a smaller blower. I think all of these companies are constantly trying to push that envelope.”

While you may be able to make similar horsepower with smaller superchargers as you can with something larger, Jason Saris of Saris Racing Engines, says that depends on application.

“Supercharger sizes are different from the perspective of street and drag racing installations versus the marine world, which is quite different,” Saris says. “A 3 or 3.3 may be ok making 1,100 hp for a 10-second blast down a drag strip or even a 30-second blast down a boulevard. It would not be the right choice for an offshore marine engine producing 1,100 hp for an hour or more at a time. The 4 or 4.5 liter blower would be a far better choice as it would produce the boost needed to achieve 1,100 hp with a much slower rotor speed and way less heat. With the smaller supercharger, the high rotor speeds would cause the intake temps to climb as the heat builds. It’s ok for short durations, but unacceptable for the long haul.”

When it comes to TorqStorm’s offerings, they have one blower and that’s it. They’re all the same size, so it’s a matter of either running one or two.

“In our testing on a single, we were able to build an engine in the 750-horsepower range and it only robbed 40 horsepower from the engine,” he says. “You can generally see a 200 horsepower increase in most cases on a single supercharger from them. If you hang the duals on there, obviously you can make over 1,000 horsepower.

“When you get into ProCharger and Vortech, there’s a lot of different compressor sizes and styles. On the low end, using a single serpentine belt you can make 700-800 horsepower. If a guy wants over 1,000 horsepower, then you’re going to step up to a YSI or an F1R for ProCharger and something like a V-30 for Vortech.”

Key Component Upgrades

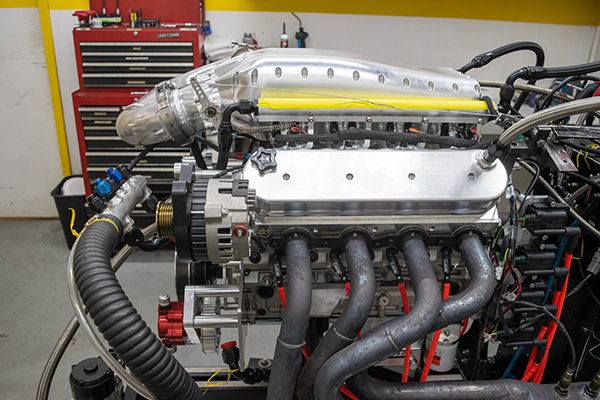

Keep in mind that running a supercharger means more stress on the engine and higher engine heat, so make sure your components can handle it to ensure longevity.

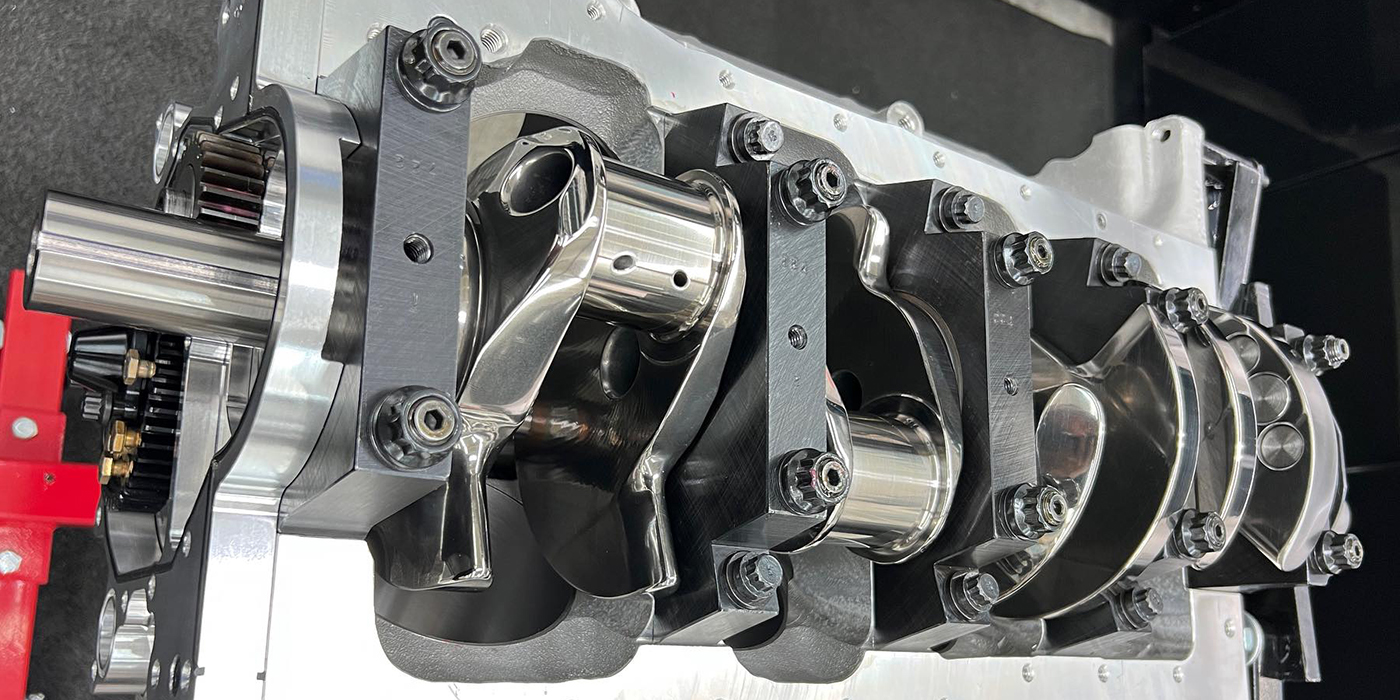

“When you’re supercharging an engine, you need good internals,” Aitken says. “We like using forged cranks, H-beam rods, ARP 2000 or better bolts, and forged 2816 pistons with a severe-duty heavy wall pin. Outside of that, depending on the engine itself, would be the head gasket area.

“Engines like the LS are very similar to the Ford in that they don’t have many bolt holes per cylinder, until you go to the aftermarket block and cylinder head options. Depending on what we have for clamp load, we might introduce a fire ring instead of just a traditional MLS gasket to have some peace of mind. We always know that people are going to push the engine harder, especially if they change the pulley out, and now they’re making 1,100 horsepower and we’ve got a head gasket issue if we didn’t do the upgrade.”

Lastly, because superchargers generate heat, you’ll want to make sure you’re using an intercooler to help cool the air coming into the engine from your supercharger. Superchargers with higher boost will create a hotter discharge, so as you increase your boost, the effects of the intercooler become more and more noticeable. No supercharger alone will ever begin to match the efficiency of an intercooled supercharger.

The bottom line is that intercooled boost is substantially more powerful and safe for your engine than hot, non-intercooled boost. Intercooling reduces intake temperature, provides full timing, allows for more low-end boost and horsepower, an expanded power band, and did we mention more boost? EB