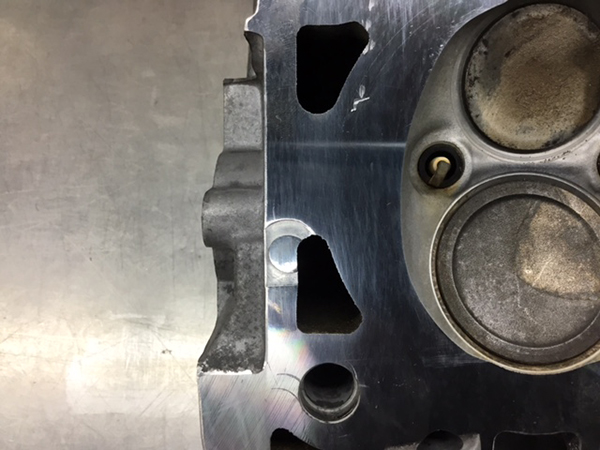

WATCH FOR THE GROUND STRAP

This happens far too often. After servicing late Chrysler Hemi heads, they’re back within a day or two. If the installer is not careful, they get the ground strap between the head and the gasket during installation. Once they are torqued down, the damage happens and leaks will appear at start up. The head will be back for repair. I try to warn the customers to be aware when they pick up their heads the first time.

Tom Prodahl, Cylinder Head Service, Minneapolis, MN

LS SPRING HEIGHT

Measuring installed height on LS or any other engine with beehive or small OD retainers can be tricky without a special height mic. But if you take your standard height mic and flip it upside down, it will work. You will likely have to take a measurement without the locator installed, so just subtract the locator thickness from your reading.

Nick Jones, Automotive Machine, Fraser, MI

QUICK T-NUTS

Start with a carriage bolt with a head diameter 1/4˝ larger than the bottom of the T-slot. Be sure the bolt’s square shank fits easily into the T-slot. Chuck the bolt in the lathe, drill and tap through the head to a depth just beyond the end of the square shank. (If the bolt has a little run-out, it won’t matter.)

The distance from under the bolt’s head to the top of the head cannot be greater than the clearance gap of the T-slot. Faceoff the bolt head as needed. Part off just past the square shank, so the distance from under the head is less than the thickness of the upper portion of the T-slot. Finish by grinding two parallel “flats” on the bolt head until it fits easily in the T-slot. This can be done quickly and easily by eye. I often need a few extra T-nuts, or I need a T-nut with a smaller imperial thread or a metric thread than what comes with clamping kits.

Tom Nichols, Automotive Machine & Supply, Inc, Cleburne, TX

THRUST WATCH

As engine builders we always make sure the crankshaft thrust is proper before assembling the rest of the engine. I believe we should also be measuring it again when it is in the vehicle, because there are so many possible flywheel/clutch, torque converter and transmission combinations that it is important to verify components that are coupled to the engine are not causing problems. I believe that it would be a good idea to add to the customers engine check-off list if you are not performing the install.

Dave Matton, D and D Auto Machine, Bloomington, MN

BLUE BE GONE

Metal parts that are exposed to too much heat will turn a shade of blue. I found that brushing white vinegar on the eye of the connecting rod, after heating to install pistons, removes the blue. Put vinegar in a plastic container for dipping small parts and it works quickly. A couple minutes then a rinse and dry gets the blue out. The blue finish may not hurt anything, but it’s one less thing for some customers to question.

Randy Torvinen, Torvinen’s Machine, Menahga, MN

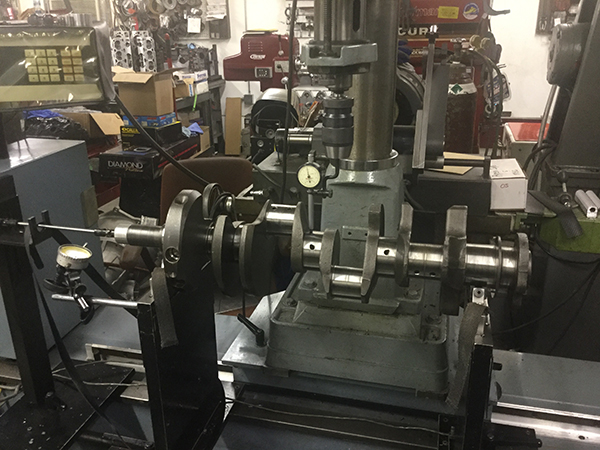

GET IT STRAIGHT

When balancing crankshafts, I feel it is imperative that the crank straightness be checked and corrected before any balance work is done to ensure accuracy. I have an offset indicator that I’ve come up with that mounts right in the mill drill on the machine. If I need to straighten a crank, I do so and verify before setting up for balance.

Ron Flood, Cedar Machine, North Branch, MN