It is often true that “the squeaky wheel gets the oil,” both literally and figuratively. In the past, this maintenance activity had to be done with a petroleum-based lubricant. Fortunately, in answer to today’s emphasis on greater environmental responsibility, Cortec® has made it possible to give the squeaky wheel the biobased oil in the form of EcoLine® ELP all-purpose lubricant.

EcoLine ELP is a high-performance biodegradable soy-based lubricant and penetrant for general purpose use. It is formulated from natural seed oils and select additives that offer lubricity and performance superior to conventional lubricants. Its performance, biobased nature and low environmental impact make EcoLine ELP a desirable option for the environmentally conscious.

EcoLine ELP contains 95% USDA-certified biobased content, surpassing minimum biobased content requirements for products falling into the BioPreferred category of multifunctional lubricants. In addition to being biobased, EcoLine ELP is biodegradable, chlorine-free and not toxic to plants—a much friendlier environmental prospect than petroleum-based products in case of the incidental leak or spill.

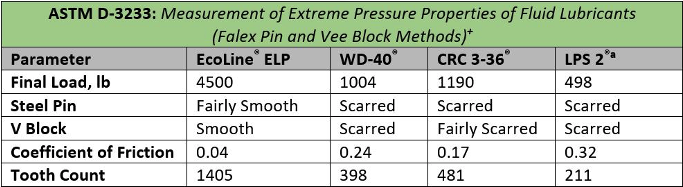

When tested according to the ASTM D-3233 Falex Pin and Vee Block Test, which demonstrates the extreme pressure properties of lubricants, EcoLine ELP was able to hold up under a much heavier load than the other lubricants while avoiding scarring. Compared to WD-40 and CRC 3-36, it was able to withstand nearly four times the load; compared to LPS 2, it was able to withstand nearly 10 times the load. Coefficient of friction for EcoLine ELP was also significantly lower than the competition.

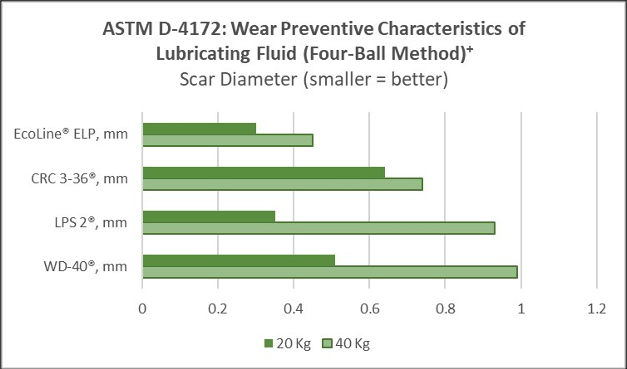

When tested according to ASTM D-4172 Wear Preventive Characteristics of Lubricating Fluid (Four-Ball Method), EcoLine ELP showed a much smaller scar diameter than the three other products.

EcoLine ELP and the three other products were tested by applying them to rusty nuts and bolts and leaving them to sit for 15 minutes. Then they were unscrewed, and the torque was measured. EcoLine ELP fell into close range with the performance of the competition. Also, although corrosion protection is not the main purpose of EcoLine ELP, parts treated with it passed more than 3,000 hours corrosion-free in 100% humidity at 50 °C (122 °F) (ASTM D-1748), comparable to the competition.

There are many possible uses for EcoLine ELP around the shop. Chain and gear systems need frequent lubrication and are often out in the open at risk for outdoor leaks and spills where a biodegradable product would be preferred. Nuts and bolts that need to be easily removed for equipment access and fans, wheels, and hinges are other common moving parts where biobased EcoLine ELP can be introduced.