Engine of the Week is presented by

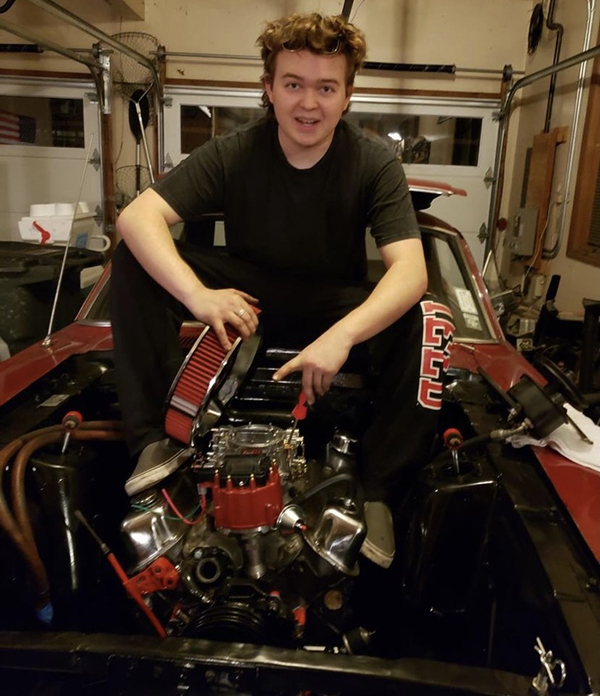

Daniel Mishustin is a unique sort of engine builder. He’s young, self-taught and has a fairly large social media presence where he documents all of his progress. He’s not a professional engine builder, yet. In fact, Mishustin’s current project is his first major build, and it’s quite the undertaking for someone new to the industry.

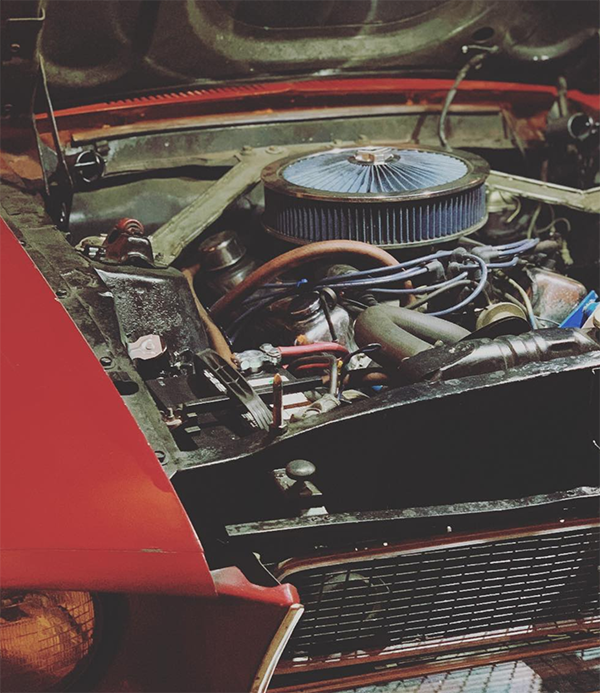

Mishustin made it his goal to completely rebuild a crimson red 1968 Mustang, which he aptly named Ruby upon purchase.

“I really don’t have a super interesting story about how I got into the automotive industry,” Daniel Mishustin admits. “I’ve just always been super fascinated with cars since I was a kid and how these giant machines with thousands of individual parts are part of our everyday lives. I’ve thought about starting a project like this for a long time.”

YouTube serves as an asset for many aspiring mechanics and engine builders to learn something new from different channels and personalities. In fact, Mishustin’s roots in the automotive world stem from tutorials he watched on ChrisFix, a popular YouTube channel that publishes general step-by-step tutorials on how to fix and maintain a car.

At only 15, Mishustin used what money he had to buy a 1979 Chevrolet Silverado and fixed it up using what he had learned from YouTube. Today, Daniel is 21, and he’s nearly finished up bringing Ruby back to life.

He originally bought the ’68 Mustang in upstate New York off of Facebook Marketplace in 2018. He ended up arriving and buying the car in the dead of night, so he was unable to fully diagnose the car’s condition, but he still decided to trailer the car back home to Old Tappan, NJ.

“It was pretty horrible when I bought it in terms of the overall condition,” Mishustin says. “It was completely rusted and the chassis was rotted out. It had a 302 Windsor V8. It ran and drove, but it would barely start and you’d have to put it on your calendar as to when you’d actually come to a stop.”

Daniel first attempted to rebuild the original 302 in 2019, but after spending countless hours on the project, he was defeated by a severe case of rod knock (the wrong connecting rod bearings were used). He decided a full, ground-up rebuild was the only option.

“It was pretty disappointing, and obviously the whole thing was a huge learning curve for me,” he says. “I really learned the intricacies of building an engine along the way, and I decided the second time I’d do it the right way.”

In 2020, Mishustin took the engine out once again to start from scratch. This is when he began documenting his build on social media, where he garnered tens of thousands of likes per video.

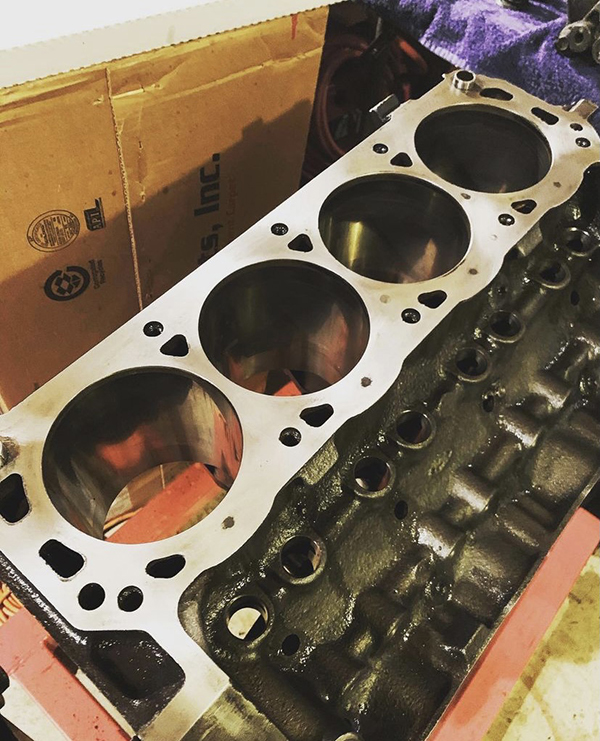

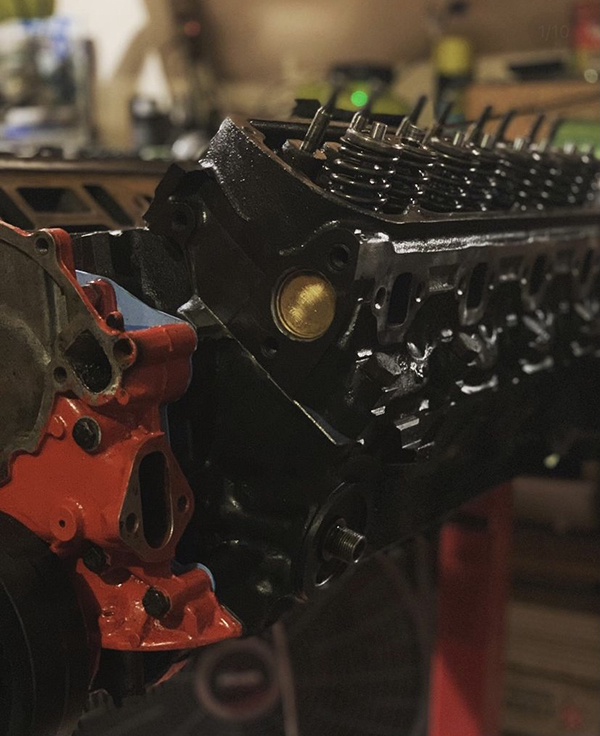

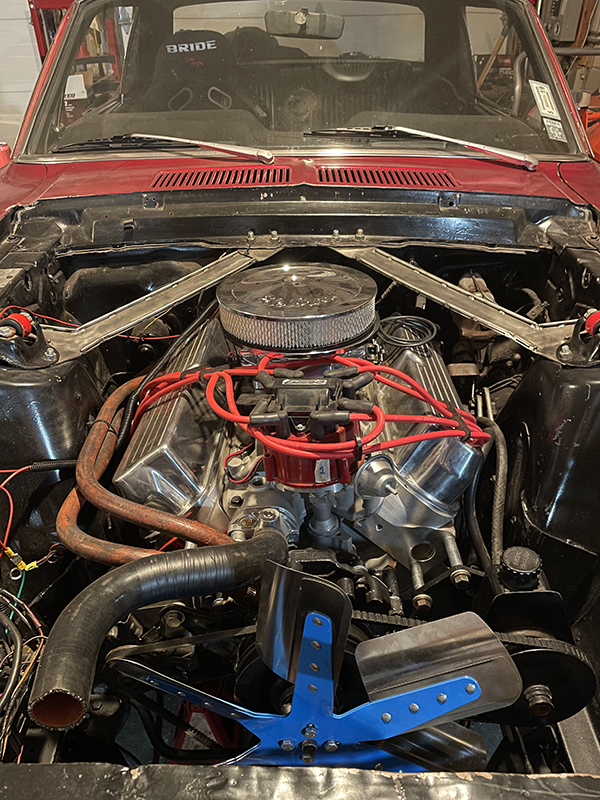

Everything on the 302 was replaced except the block, which Mishustin cleaned up and had machined.

“After I got all that done, I was like, ‘A 5.0L really is a great motor, I can make good power with that, but a 347 sounds way cooler and I’d rather have a 5.7L for the bigger displacement.’”

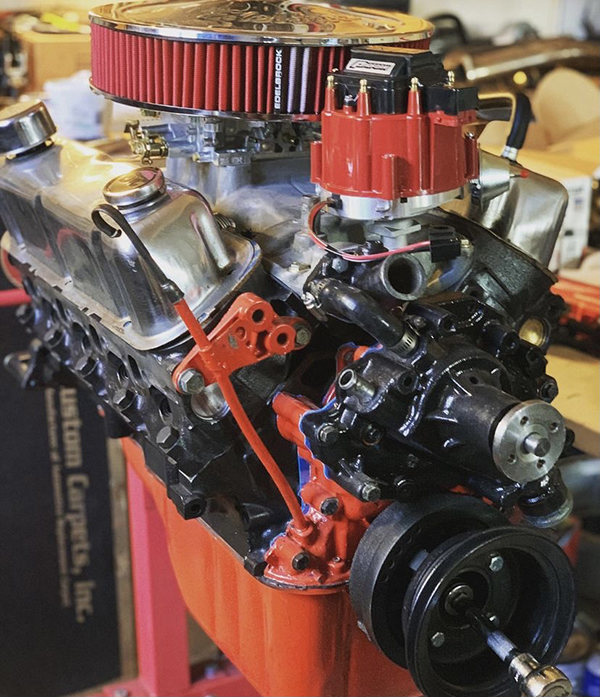

As such, he got a forged 347 stroker crankshaft for the new build. He also chose to use DSS SX series forged pistons, which were CNC machined for valve reliefs. And, he went with a set of Speedmaster aluminum cylinder heads, which got decked.

Besides added horsepower, Mishustin’s next goal was reliability. He didn’t want to have to rebuild the engine a third time. He installed forged connecting rods, which have a rod cap that’s forged separately so the grain flow runs perpendicular to the load force for added strength. The rods also include high amounts of nickel and chrome, which increases strength and fatigue life.

Mishustin went with a Ford Performance camshaft to aid in the racing application he plans to use Ruby for in the future. The lifters and the valve springs Mishustin chose will also help improve performance at higher rpms and higher oil temperatures.

To top it all off, Daniel used a Holley Sniper EFI kit to help provide consistent performance and greater fuel efficiency. He’ll finally be able to start the engine up once he receives the rest of the fuel system parts shortly.

Although it hasn’t become a reality yet, Mishustin’s vision is to eventually fit twin turbos on the 347. For now, the compression ratio on the naturally aspirated engine isn’t super high, but Mishustin went for a larger combustion chamber than he needed to make it safer for him to boost it later on.

“I wanted to build it naturally aspirated first just so I know the engine is solid as a main platform,” Mishustin says. “Once I have it to where I like it, I’ll start looking into twin-turbo setup opportunities.”

With the 347 Ford nearly finished up, Mishustin expects Ruby to get around 500 horsepower, which is more than enough to get him around the track.

“Even though it’s an old car with crappy suspension, one day it’s going to be at a racing level,” he says. “It’ll have a good, healthy motor that not only I can take around turns, but I could throw it down with someone going down the highway.”

With 500 horsepower on tap already and a twin-turbo setup planned for the future, this 347 stroker will definitely be ready to throw down.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].