Dirt Late Model racing was originally a grassroots division that sported old Ford coupes with Flathead Ford V8 engines and home-built race cars that were VERY unsafe. These racers risked life and limb for a trophy.

The division has now become professional in every way possible. Multi-million-dollar purpose-built dirt racing facilities that hold thousands of spectators are now the norm. Major sanctioning bodies that promote over 100 races per year paying millions of dollars in prize money AND a trophy. The race cars are $100,000 purpose-built factory race cars with engines that can hook-up 900 horsepower on dirt. Dirt Late Model racing has come a long way in 70 years or so.

There are two major sanctioning bodies in Dirt Late Model racing – the Lucas Oil Dirt Late Model Series and the World of Outlaws Late Model Series. Both of these sanctioning bodies promote 50-60 races per year each with prize money varying from $10,000 to $100,000 to win every race. Both series pay their season champion $125,000 – $150,000. Both sanction bodies have races on TV, and some of them are live. As you can see, Dirt Late Model racing is BIG business.

The business side of Dirt Late Model racing is one thing, but the main reason for this article is to discuss the engines involved in Dirt Late Model racing. Nearly all, about 99% of the engines used in this type of racing, are either small block Chevrolet or small block Fords.

The small blocks are preferred over the big blocks because of their lighter weight for better handling through the turns. In this type of racing, the way your car drives through the corners is way more important than horsepower down the straights.

One thing to remember about these engines and this style of racing is that it is truly a ‘run what you brung’ and ‘hope you brung enough’ division. The rules are very minimal. Two valve per cylinder pushrod V8 with one carburetor on gas. That’s it!

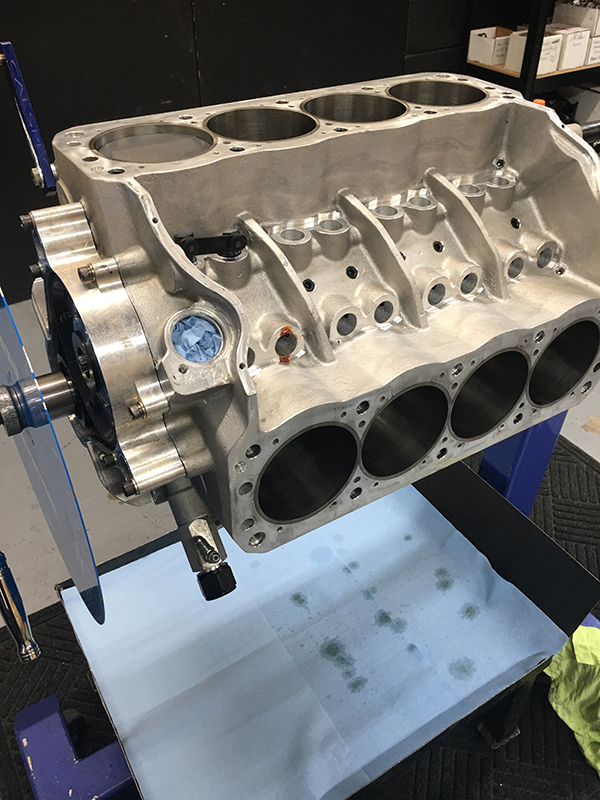

The small block Chevrolet that is used in Dirt Late Model racing has evolved from the original 1955 265 cubic inch V8 small block. The blocks these days are made from aluminum with steel main caps and the bore centers have been widened from the original 4.400˝ to 4.500˝. This allows you to run a much larger bore.

The crankshafts and connecting rods are both billet steel and are paired with a forged or billet aluminum piston with low tension rings for less drag on the cylinder walls. Roller cam bearings are used in conjunction with 55-60mm camshaft journals for less camshaft deflection. Camshaft belt drives are used for less valvetrain harmonics. Large diameter roller lifters are used for better valvetrain stability.

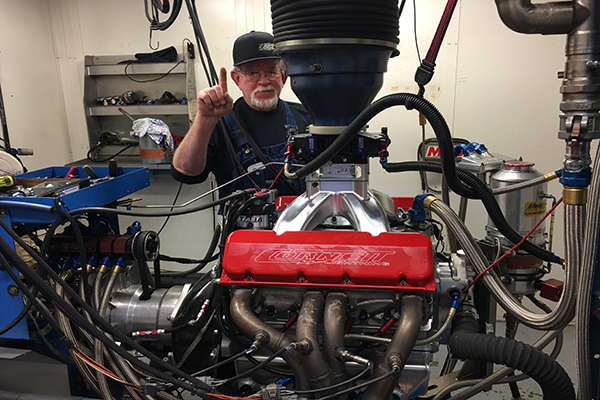

On the oiling side of things, aluminum dry sump oil pans are utilized with up to four pick-ups inside the pan for better oil scavenging. The aluminum cylinder heads used will vary from engine builder to engine builder, but anything goes, so each builder has their own design that hopefully will give them an advantage over the competition.

When it comes to cylinder head selection, you’ll typically find 10- and 11-degree valve angle heads along with SB2-type cylinder heads as well. Titanium valves will be used exclusively with the latest trend in valve springs, which is a very small diameter spring with low seat pressure. The rocker shaft system will utilize steel rockers bolted to a very rigid steel stand along with large diameter, thick wall pushrods. This keeps the valvetrain stable for 9,000+ rpm.

Up top, the intake manifold choice also varies between the different engine builders as everyone has their own secrets. You will see anything from a cast, hand-ported manifold to an exotic, CNC-ported, billet manifold.

In addition, most engine builders will look for added performance through the use of different types of coatings on different parts of the engine. Bearings, pistons, piston pins and valves are popular areas where applied coatings can help the engine parts live longer.

The small block Ford that is used in Dirt Late Model racing has evolved from the 1968 351 cubic inch V8 Windsor engine. The Ford is built in exactly the same way as the Chevrolet engine. The most popular cylinder head for the Ford engine is the D3 Yates head. This cylinder head was originally developed for Outlaw type engines and then was used by Ford in NASCAR until the introduction of the current FR9 program.

The two engine packages (Ford and Chevy) make about the same peak torque and horsepower numbers, but the big difference is in how they drive on the race track. Generally, the Ford has more power above peak horsepower and the Chevrolet has more power below peak torque. Each driver is an individual who wants his engine package to perform in a certain way, so inherently some drivers prefer Chevys and some prefer Fords.

The stresses involved in a Dirt Late Model engine are incredible. I personally think these engines are more stressed than any other type of oval track racing engines. Dirt Late Model engines are making 700+ lb.-ft. of torque and over 900 horsepower! They have a very high compression ratio and the rpm varies from 2,500 to 9,000+!

Pistons are one of the more highly stressed components due to exposure of speeds of almost 6,000 fpm! These engines also have to run 600+ miles before a rebuild, typically. Valve springs are changed at the 300-mile mark as these components are also prone to premature failure. One big issue is keeping them cool. Since the noses of the race cars are scraping the ground, no air gets under the nose. In fact, you can’t have any grill opening on the cars because you will pack your radiator full of dirt!

In short, building a competitive Dirt Late Model engine is one of the most challenging endeavors a performance engine builder can do. If you find success, it can be a very rewarding market, and one in which racers will keep coming back for more. EB