Engine of the Week is presented by

Sammy Maloof is a man of many talents, and as such, he’s lived a fairly storied life thus far. He is also a man who credits God for helping him live the life he has, because it wasn’t always on the straight and narrow.

Sammy grew up involved in a number of different “hobbies,” making a living early in his life three ways – illegally street racing, arm wrestling and bare-knuckle barn fighting, and engine building. It was God who told Sammy he needed to follow a slightly different path to unlock his true potential.

“I’m a big time Christian,” Sammy Maloof says. “I’ve got to give credit where it goes. On my way to a street race for $2,000 at a place called Kevin’s Burgers in Canoga Park, CA, God said if I quit street racing, he’d give me a race car. That night, I quit… Two months later, God gave me a race car and I’ve raced that car for 36 years.”

Maloof was a pretty prolific street racer in his day. He used to earn $2K-$5K a week at it. Obviously, he never quit racing, but he quit using his talents in nefarious ways. There were plenty of other callings his talents would be well-suited for.

“God never told me to quit racing,” Maloof says. “He told me to quit illegally street racing. He never told me to quit fighting. He told me to quit fist fighting. He never told me to quit arm wrestling. He told me to quit arm wrestling for money. I took all my gifts and talents and I used them in the movie industry as a Hollywood stunt man for over 25 years. And, I’ve had my race car shop for 37 years.”

Sammy’s 25 years as a stunt man has been chalk full of fights, falls and fire, but his specialty is vehicular stunts. His IMDB page features tons of movies and TV shows such as Rush Hour, Wild Wild West, Enemy of the State, Three Kings, Gone in 60 Seconds, The Fugitive, Swordfish, 2 Fast 2 Furious, The Fast and the Furious: Tokyo Drift, Mission Impossible Ghost Protocol, Burn Notice, Charlie’s Angels, and Transporter 2 – to name only a few. “God has given me a gift in driving,” he says.

Two of Sammy’s standout driving stunts were one from 2 Fast 2 Furious and one from the TV show Ice Road Truckers – both of which require serious skill due to the danger involved.

“In the movie 2 Fast 2 Furious, I was the cat driving the convertible Corvette that was never supposed to flip,” he says. “When the 18-wheeler ran over the Mustang in front of me and I hit it driving the Corvette, it went straight up in the air, flipped and crushed the convertible roof to the ground. There was no roll cage in that car, but I didn’t rule out God. He told me what to do before the stunt took place. Not one hair on my head was touched.

“However, one of the biggest puckering stunts for me was doing Ice Road Truckers. They hired me to drive an 18-wheeler 11,000 feet up in the Beartooth mountains and in reverse, back up at about 40 mph, jack knife it, and flip the trailer over without going over the cliff. You have no control in the snow. You’ve got to just go for the ride.”

While danger is never very far away when performing stunts of that caliber, it’s further from your doorstep as an engine builder, but it’s no less exhilarating to build some of the fastest engine and car combinations around. Sammy has been doing it since he was just 13 years old!

“My whole life I’ve been building engines,” he says. “My first small block Chevrolet I was 13 years old. It was a 283 I put together. I had mentors and people who were machinists who would give me clues on what to do. I learned tips from them. Then at 16, I built my truck, which was a small block Chevrolet – a 12.5:1 compression, 355 cubic inch Chevrolet engine with a Tunnel Ram on it. I started street racing that truck all over when I was in high school and I was making serious money in a ‘64 Chevy pickup.

“Then, when I was about 18 or 19, I got my ‘68 Z28 Camaro. The first engine I built for that was a 310 cubic inch engine. I had a Super T10 with Liberty gears. That’s when I started really making some big money. I would trailer my Camaro to street races and unhook my truck. I would tell people if they could beat my truck, I’ll pull my Camaro off. We would put up $3,000, $4,000, $5,000 and I would take their money.”

His success on the street led to a necessity of building better engines, and others wanted Sammy to build engines as well, so he left his parents’ house for his race shop, Maloof Racing Engines, which he opened in 1984 in San Gabriel, CA.

“I’ve been here for 37 years,” Maloof says. “I started out working on everything, but I specialized in high performance. I quickly transitioned from stock stuff right into racing stuff – road racing, drag racing, Winston Cup motors – big cubic inch Chevy or Fords. I did that for not only customers all over, but I did it for the movie industry and my own family. Today, I only build engines that are Detroit iron – Chevy, Ford, Chrysler, Pontiac, Buick, and Oldsmobile. I build them for people all over the United States.”

Maloof Racing Engines is an 11,600 sq.-ft. facility with a two-bedroom house and a recording studio upstairs, and the shop space downstairs. Sammy’s wife, Jennifer, and his three daughters, Hannah, Meghan and Kaitlyn, each work in the shop, as well as Sammy’s adopted son Trevor and nephew Joshua. It’s a family business.

“I raised three daughters at my race car shop, homeschooling them,” Maloof says. “Today, my daughters race cars and they build engines and they do stunts. Jennifer runs the office and Trevor and Joshua help builds cars too.”

Any of the shop’s serious machine work gets done by a select few that Sammy has gotten to know over the years. Maloof uses Larry Mollicone, Blair’s Speed Shop, Steve Schmidt and TEAM C Performance for machine work and parts.

“I’m detailed when it comes to building engines,” he says. “I want things done exactly the way Sammy Maloof wants them. Not the way anybody else wants it. For transmissions, I get them from one place and one place only – from a guy by the name of Marco Abruzzi of Abruzzi Racing Transmissions in Ohio.”

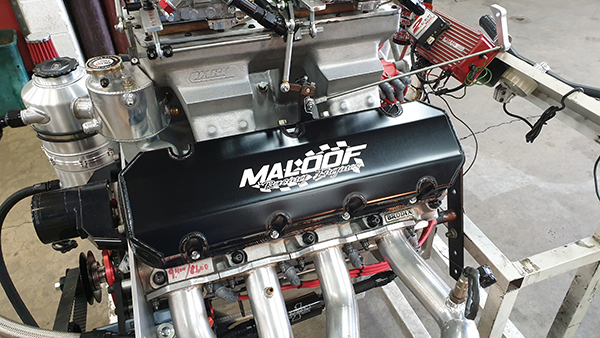

One of those Detroit iron, big cubic inch engines that Sammy recently completed was a 635 cid, all-aluminum, big block Chevy for a drag racer named John Kitterman, who drives a ‘68 Nova.

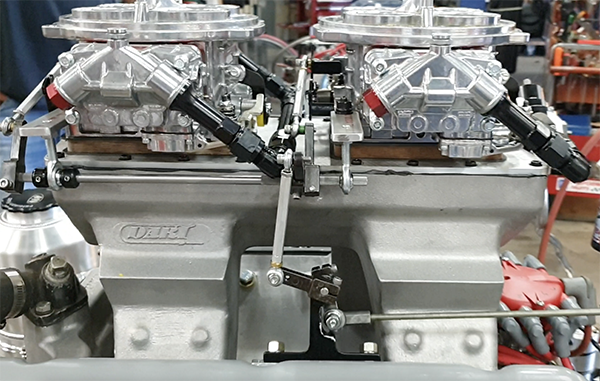

“It’s 16:1 compression and it’s normally aspirated,” he says. “It has a billet crank, Carrillo rods, JE pistons, a Brodix block and Brodix heads. It also has a Dart dual quad intake manifold with two Quick Fuel 1050 carbs on it. Isky Cams made the camshaft to the numbers that I wanted.”

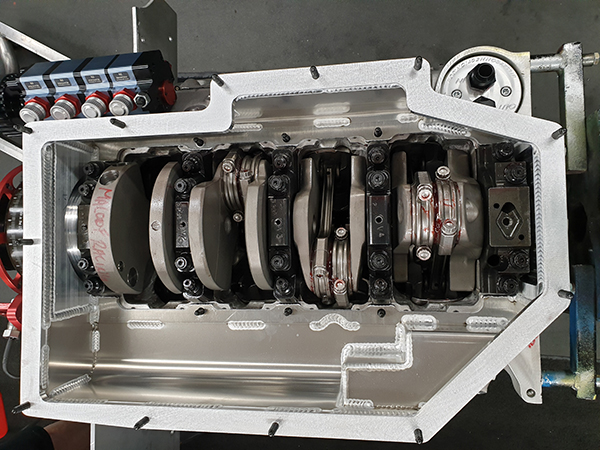

According to Sammy, the 635 BBC has a 4.610˝ bore and 4.500˝ stroke. The engine has a 55mm cam journal and it’s all roller bearing. It also has a Jesel belt drive set up, T&D shaft mount rockers, Manton pushrods, and Isky Red Zone EZ Roll lifters. The engine runs on a Weaver Brothers four-stage dry sump oiling system with a Moroso custom-built, two-piece oil pan underneath.

To make his big cubic inch engines really perform at their peak, Sammy says there are two things he ensures with every build – oil specifications and the camshaft design.

“After 30-some years of building racing engines, nothing is better than a conventional motor oil with a lot of zinc,” Maloof says. “I don’t run multi grades. I run straight grades. I don’t believe in restricting motor oil to the top end of the engine. A lot of people do, but I think you’re just running yourself into a problem. If your can is being emptied on oil, you need to have a better drain system. Don’t restrict the top end of these engines because valve springs need to have cooling. The way you do it is you oil them. To keep all the valvetrain components running good, you cool it.

“When it comes to designing camshafts, I’m a big believer on big cubic inch engines, unless they’re on alcohol, I do not widen my cam lobes. There’s a certain lobe separation I use. I know a lot of the big dogs like to widen them way up. My theory is if you’re going to put the air and the fuel in, why are you taking it out before you build cylinder wall pressure? A lot of guys widen these lobe centers up so much that you’re not building enough cylinder wall pressure and they’re depending on the cubic inches of the engine to move the car.

“We like to run these big cubic inch engines somewhere between 7,000-8,500 rpm, depending on the cylinder head. My biggest thing is this – I need to generate torque. Torque is what moves the car. Torque is accelerating horsepower. If I’m going to run a huge camshaft, I start an engine at 16:1 compression. You need to get the right cylinder head that works with that engine too. I build a lot of engines off of torque.”

This particular 635 cid big block Chevy engine produces 1,450-1,470 horsepower normally aspirated, which gives customer John Kitterman a mid-to-high 4-second, 1/8th-mile ‘68 Nova. He races the car in the Summit series as well as for bracket races.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and Scat Crankshafts. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor, Greg Jones at [email protected].