Building racing engines and race engine components is something I have been doing for as long as I can remember. I was blessed to be born and grow up in Southern California, which is where many would argue the hot rod racing industry started.

For a large part of my career, I made engine parts such as crankshafts, connecting rods, engine blocks, and pistons. All of the parts I was involved in making were manufactured for racing applications such as NASCAR, NHRA, USAC, Dirt Late Model, Sprint Car, Offshore Boat Racing, and IndyCar. You could say that I had access to the top engine builders across the country in most every single aspect of racing.

Having the ability to travel and visit individual shops, you get a quick education on what it takes to be at the top of the game. Obviously, as you go along, many of your customers become some of your close personal friends as well. At times, I might even consider this to be an unfair advantage. Being able to simply pick up the phone and call for advice or input on a build I am doing, or ask if another builder across the country were having similar parts related issues that we may be having is priceless.

About five years ago, I had a customer contact me about building an engine for an off-road racing team, and that’s how my shop, Jeff Ginter Racing Engines (JGRE) was born. It wasn’t that I had a premeditated idea of going back into the racing industry, it organically just happened and then the next phone call came and the next phone call came and so on. Within a short period of time, we became the ones that everybody wanted to take to the prom, so to speak. That’s how it’s gone and that’s how it’s continued to go and to grow today.

Our shop is located in Artesia, CA, and our performance engines are built for desert racing, marine and four-wheel-drive applications.

If you were to go back roughly 10-15 years ago, and if you were to ask anyone what would be one of the toughest, most demanding engines to build? Almost without a doubt it would be offshore boat. Massive catamaran and cigarette boat hulls with multiple engines running for extended periods of wide open throttle (WOT) at near peak torque combined with leaping in and out of the water with the massive outdrives and propellers is extremely brutal on an engine. It’s like being hooked up to a high-load dyno on steroids nonstop. These engines were strained beyond belief and were truly the test bed for most hardcore parts manufactures.

As the off-road racing community and technology grew, so did the vehicle speeds and related suspension components. Today, these are without a doubt one of the most highly strained engines in motorsports – bar none. Depending on the class, you are talking about 750–1,000 horsepower and 675-800 lb.-ft. of torque moving these vehicles through the desert at speeds nearing 170 mph.

What sets these engines apart is the never-ending loading and unloading of the drivetrain. The tire and wheel combinations are now over 150-lbs. or heavier. These vehicles run in and out of peak torque, sometimes in excess of 10 hours at a time, and it beats up the entire drivetrain in terms of loading and unloading. If you are not running the best of the best in terms of engine components (and every single component on these trucks) you will without a doubt have a catastrophic engine or part failure.

These vehicles send shock loads so harsh and so severe that we will see the end results of the harmonic and transient frequencies clear up in the valvetrain. Standard aluminum shaft mount rocker arms will no longer live in these engines – they must be made from high-quality steel and have several other component changes made to them in order to live.

Titanium retainers will no longer live in this environment either. They must be made from tool steel. The camshafts are now having to be made from tool steel as well in order to withstand the never-ending loading and unloading these engines take.

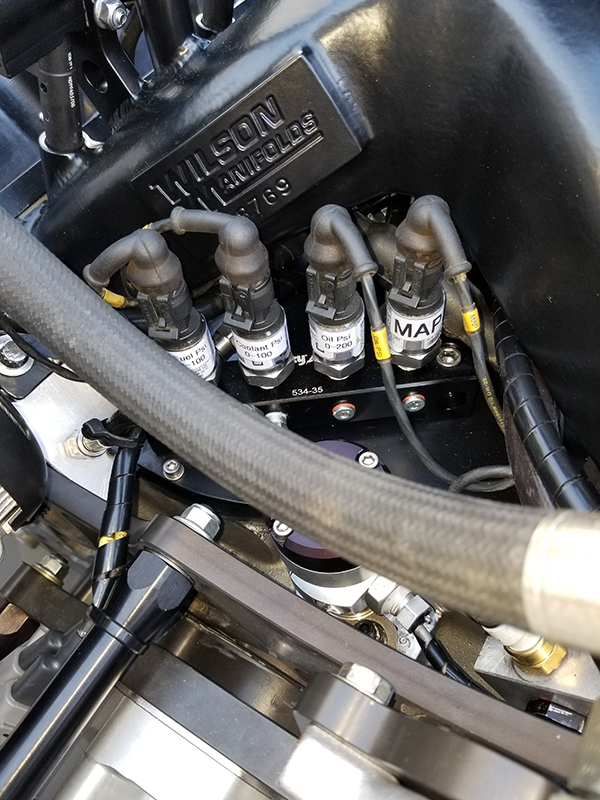

Carburetors in this engine application are a thing of the past due to the pounding they take and the constant issue of flooding over. We now run very sophisticated EFI systems. Most of these engines now run a redundant sensor system, meaning that they run two throttle position sensors, two crank sensors, two cam sensors, two MAP sensors, two oil pressure sensors, two fuel pressure sensors, two coolant pressure sensors, two knock sensors, two fuel pumps, etc.

In the case of a primary sensor failure, the secondary sensor automatically and seamlessly is moved into place without notice. This is the level of sophistication these vehicles and engines are now running at. A simple sensor could have taken you out of a race in the past, so now we have a complete redundant system.

With many of these off-road races lasting 500 or even 1,000 miles, you might think the margins of victory are very spread out. However, that’s not even remotely the case. Often times, these races are decided by mere seconds and minutes, so a component failure is not an option.

The life span of the higher end engines now range between 1,000–1,200 miles before racers will need to bring them in for a complete 100% tear down and rebuild. There are also mileage or life span cycles on certain components like cranks, rods, pistons, and valvetrain parts – at a certain point they are simply retired and replaced.

Until you actually go to one of these races and experience it live or firsthand, it is hard to wrap your head around the concept of how much abuse these engines and vehicles take. Simply stated, if you can build an engine to live and survive in this kind of environment, you are doing something right. This style of racing is not for the faint of heart.

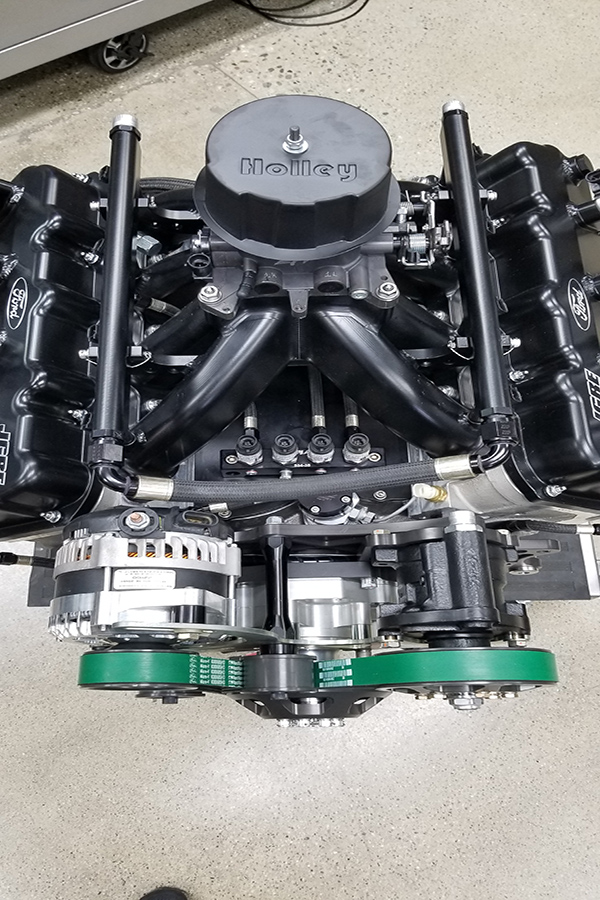

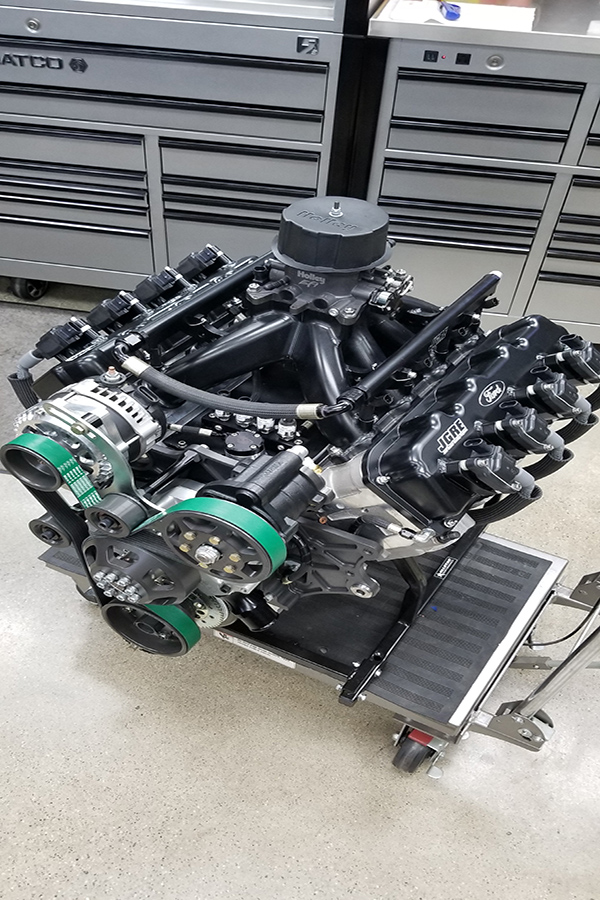

Here at Jeff Ginter Racing Engines, we are both very proud and honored that in 2021 we built the Ford off-road race winning engines for Vaughn Gittin Jr., who has successfully transitioned from a championship Formula Drift driver to one of the top contenders in the Ultra4 Off-Road series. Vaughn and his teammate Loren Healy are running several of our small block Ford EFI “D3” based engines in their new “Bronco” race trucks.

Just keep in mind, the next time you’re looking to build an engine for off-road racing, or if you’re planning to be behind the wheel, make sure you have the best components involved. If you don’t, you’ll be watching the race from the sidelines or fixing a lot of engine issues. EB