At Moran Motorsports, the engine development shop focuses on high-horsepower performance engines, and specifically, stuff that most other shops can’t do thanks to their custom design work. If you want stuff off the shelf, obviously, there’s lots of shops that will do it. But, if you want something that nobody else has, Moran Motorsports owner, Mike Moran, usually gets the phone call.

“We do a good deal of Outlaw Pro Mod engines,” Moran says. “We don’t do a lot of “legal” NHRA engines, but there isn’t that much difference between that and illegal ones – maybe .020˝ difference in terms of the valves and port volume might be 10cc different – but they’re basically the same engines. It all comes down to induction, camshaft, compression, ring packages, etc. We build them for pretty much anybody that wants one and wants the elite package.”

The biggest difference between Outlaw Pro Mod engines and what you might see in NHRA competition is the limitation on valve size and the CCs on runner volume.

“That architecture doesn’t allow for a lot more, but there’s a little more there,” Moran notes. “You can open them up about .020˝ one way or the other. The compression is also going to be different because in NHRA they have a boost number that they allow – currently 33 lbs. Due to that, you have to put a lot more compression in them, so the volumetric efficiency goes down with a dome. We go the other way. We go with a little less compression and we look for volumetric efficiency to be higher and more efficient. Then, we get the rest in the ring pack and piston design and stuff like that.”

It’s not really a secret that big domes aren’t very efficient. The key is finding out how to keep compression with less dome and that’s all done through the camshaft. You want to try and target something with the best volumetric efficiency without jamming a bunch of dome in there and trying to band-aid it.

“If you get the smallest dome possible and try and fix the rest of it with camshaft to keep compression trapped in there, and then lobe separation to keep the overlap down, those are the guys who are really trying hard,” he says.

Since some drag race engine builders are limited by rules, it can be really hard to build spec motors. Regardless of the engine builder doing the work, the engines all seem to be about the same.

“When you’re allowed to have a broad canvas and you can do stuff outside of rule restrictions, that’s when you can get a really nice piece and it’s a little bit better than what anybody else can do,” he says. “Right now, everybody’s hooked on the ProCharger stuff and it’s definitely easier to go faster with a ProCharger. I think it’s all about power management. You have to be a pretty astute tuner to make a turbocharged car work as good as a ProCharged car, so everybody is on that kick right now.”

When it comes to the foundation of drag race engines these days, a majority of builders are into the Hemi and the 481X platform.

“I think in terms of the engine combination, pretty much everybody is into the Hemi,” Moran says. “However, the 481X is pretty good. It’s debatable, but the 481X seems like it might be a better target for 1/8th mile racing. But, I keep seeing more and more guys using Hemis now. It’s a really good architecture for boosted motors.

“If you were going to do an NA motor, [a Hemi] engine would not be the right thing to do – you’d want a wedge and a lot of quench area and something that can speed up the burn. With a forced induction deal, you want the hemispherical design because it’s just better to get the air in and out.”

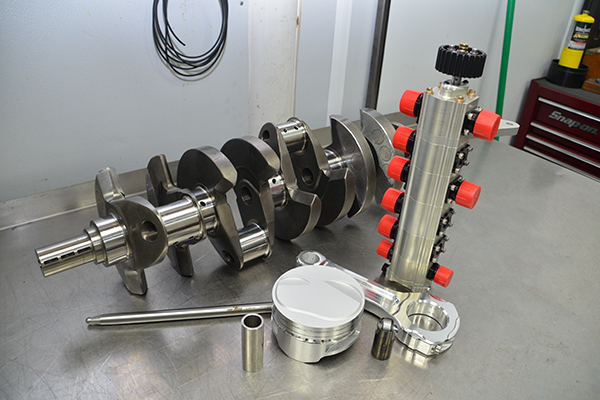

Once you’ve chosen your base, the internals for your drag race build are just as critical these days. Since most drag race engines are using power adders, Moran says his shop uses aluminum rods and billet pistons.

“We go with the aluminum rods because they’re forgiving,” he says. “In that type of atmosphere, there’s lots of really bad harmonics and frequencies and the aluminum is the only thing that absorbs it and gets rid of it. Whereas, in Pro Stock and other normally aspirated stuff, they use steel rods because they’re so dialed in and they’re trying to get to every ounce of energy and power out of their combination, so they go with really lightweight steel rods. However, those would never hold up for what we do. We need shock absorbers, for lack of a better word, and that’s what the aluminum rods are about.”

While the rod material can still vary depending on your class, the pistons used in drag race engines today are pretty much all billet aluminum now. The ring packs are also changing in that they are getting smaller, which serves an important purpose.

“A lot of technology has come along in the last five years in regards to frictional losses and stuff like that,” Moran points out. “What it really comes down to is people are starting to spend more time on development now instead of just throwing parts at stuff. They’re starting to pay attention to what the parts weigh. They’re starting to pay attention to how much frictional drag they have. They’re paying more attention to lubricants. The application is starting to actually get refined in the last five years.

“That’s really good that they’re going that direction because that’s somewhere I’ve always focused from day one and all those items add up. It seems like everybody else is starting to take notice now and starting to actually pay attention.”

Case in point, the crankshafts for these engines are all billet for added strength and lighter weight. Moran says Bryant and Winberg are two of the brands most builders chose for this application.

When you get into the top end stuff, in the higher rpm motors, if you’re going to spin up over 9,000 rpm, Moran says he likes going with rifle drilled valves to get rid of an extra 10 or 15 grams of weight. However, for any engine staying under 9,000 rpm, it’s not worth the weight savings to drill the valves and get the weight out.

“For the springs, there always seems to be a trick of the week, but if you really sit down and focus on it, some springs give better life than others and it’s all in the engine,” he says. “If you change one little thing in the engine and you change the frequency, then the springs aren’t happy anymore. You’ve got to find what spring matches everything else that you have in the engine. Whether it be the pushrod or the retainer or the weight of the valve – when you start changing one or more things, all of a sudden those springs don’t work anymore. You’ve got to try and find the springs that are more suitable and conducive to what you’re doing. That seems to always be an evolution from week to week and month to month depending on what you’re changing in the valvetrain.”

Another new thing Moran has seen is more engine builders moving to steel rockers, which is also lighter weight than in the past.

“It’s always been one of those things where nobody wanted to go with those because of the cost, and the rocker manufacturer didn’t want to make them because they were steel,” he says. “There was more cost in making them, but since they’ve raised the prices and the racers always seem to find the money to do it, you’re going to see a lot more lightweight steel rockers in engines today instead of the aluminum.”

As for the camshaft, where all these valvetrain components come together, it seems again that the industry is catching up on better ways to build these engines using a six-bolt cam.

“Everything we designed back in 2009, we designed with a six-bolt cam,” Moran says. “At the time, everything else out there had either a three-bolt or a one-bolt cam with three dowels. They also didn’t have raised cams. They just had standard location cams. It’s kind of hilarious because here we are 12 years later now ordering cams for some of these newer Hemis in the last year or two, and they’re all changing to six-bolt cams and they’re all raised cams now to get the lifter angle more horizontal and get shorter pushrods.

“People were ignoring a 55-year-old design flaw, and they were stuck on that until just the last two years. Now all of a sudden, they’re starting to wake up and they’re starting to actually put a little bit more technology into these engines, which is really good to see.”

Again, that change in mentality when it comes to this application can be seen in the oils being used in many of these engines – they’re going with lighter oils and they’re tightening up their clearances. Before, it was big clearances and thick oil and just throwing stuff at these engines. It wasn’t really refined, but it’s getting to go the other way now.

And while the engine builds are getting more refined, the horsepower levels and the abuse these engines take still causes certain issues and areas builders need to constantly be checking.

“The biggest thing you want to keep an eye on is valve springs because we’re trying to twist these things higher and higher,” Moran says. “The more rules they put on somebody, the easiest way out is trying to get the engine to spin higher. Until they put an rpm limit on something – if they add weight to you or say you can only have this much boost – the way out is to try and spin more rpm. It seems to me like the biggest attrition is in the valve springs.

“There’s always new ways to try and get the springs to live longer because it’s not uncommon to have to put springs in after three to five runs. You might not change them all, but you might change two or three every three or four runs.”

A lot of drag race engines are spinning 9,500-9,600 rpm. Some engines will spin over 10,000, but it’s a hard task to get it to go there.

“It takes a lot of focus on the small details to get it to want to be there,” Moran says. “As people find ways to get them to spin higher, they find that their performance increases, but then if you’re not paying real close attention, that’s when your longevity goes away on some of your parts. That’s the key.” EB