Diesel of the Week is presented by

Engine building is definitely an expensive industry. Most of the engines we feature in our Diesel of the Week series range from $20,000 all the way up to $80,000 or even $100,000, depending on how high tech and powerful the engine is. Because of this, it might seem impossible for the average person to get started on building a high-performance diesel for racing purposes.

There are ways to build a racing machine on a budget though, and Darcy Hanlan can prove it. Over the course of a few years, Hanlan crafted an “extreme budget race car” for around only $4,300. The car most recently made a 10.6-second pass in the quarter mile at 135 mph. Plans for that time do drop even lower are in the near future.

Although Hanlan does not work directly in the automotive industry, his experience in heavy machine maintenance and family ties to the NHRA instilled a great automotive interest in him. Hanlan’s grandfather was none other than Jim Ronaghan, who owned a famous NHRA Super Stock racing car in the late ’60s called ‘Old Trapper. Ronaghan’s car, driven by Albert Branham, was the only Canadian car to qualify for the 1968 Super Stock World Finals in Tusla, OK. His 1967 Plymouth GTX SS/B turned heads on the track and set records at the time.

“My grandpa was a great man and that’s how I grew up, seeing a 426 Hemi Dart being fired up in the garage,” Darcy Hanlan says. “Hearing wide open header, Super Stock drag cars was the norm.”

Around 15 years ago, Hanlan began building his own vehicles in his 24×28-ft. garage in Sherwood Park, Alberta, Canada. In 2008, he began working on a diesel Mustang build that he ditched after pursuing another project. Nearly 10 years later in 2018, he purchased another Mustang he had big plans for.

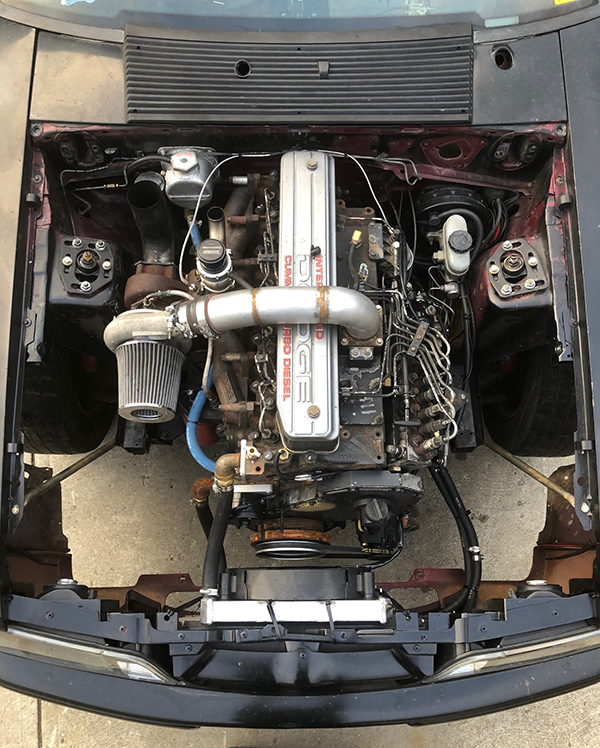

This time, Hanlan completed the project from start to finish, dropping a 12-valve 5.9L Cummins out of an old Dodge into his newly purchased ‘88 Mustang. Without the resources and money of larger diesel shops and race teams, and only his ingenuity, a six-inch angle grinder and some hand tools, he knew he would have to get creative in order to produce a competitive drag car.

“I really wanted to do something interesting,” Hanlan says. “I knew back then in 2018 that I couldn’t really compete with the boys going super-fast anymore. The money was so big and I couldn’t afford the kind of stuff they were doing. But, I thought if I could make the lightest car possible and make it go fast on some junkyard parts that people scoff at, it might just draw some attention.”

Draw attention it did. Hanlan has documented his entire build process with his race car nicknamed ‘Coalstang’ from the beginning on his Instagram page, with coverage on Facebook and YouTube as well. Virtually every part and new addition has been documented, even the weight of excess components on the engine that were removed for weight reduction.

As Coalstang continued to grow on social media channels, it attracted some larger industry names like Power Driven Diesel and Team Z Motorsports, both of which sponsor Hanlan and his diesel Mustang.

“Those guys have been amazing,” he says. “If I could go back four years and pick two sponsors, they would be the ones.”

Hanlan’s goal from the beginning was weight reduction with the frame and engine to compensate for a lack of high-end performance parts. The car weighs just under 3,000 lbs., and is actually lighter on the front axle than it was from the factory – even with a diesel engine in it. In total, Hanlan deleted 110 lbs. off the Cummins. Now, the Mustang weighs less than some cars Hanlan has raced with LS engines.

Much of the engine was left stock, including the block with 14mm main studs, the camshaft, connecting rods and pistons. The factory head gasket and head bolts were torqued to a higher specification and the mechanical lift pump was upgraded “with a few tricks.” The engine hasn’t yet been opened and the head hasn’t been off.

Many of the added components were used parts obtained from Power Driven Diesel (PDD), aiding him in his cost-efficient endeavor. PDD 5×0.018 injectors and a 215 injection pump off a ‘98 Dodge truck work to send fuel into the combustion chamber. The engine still has stock delivery valves, but Hanlan plans to upgrade to 7mm soon.

“The one upgrade you need when you’re spinning high rpms is to control the valves,” he says. “I have Power Driven Diesel conical valve springs and their upgraded locks and retainers. That’s an important one.”

Hanlan also added a Turbosmart wastegate, a JEGS electric water pump and a Fluidampr. As for the turbo system, he opted for a single JM Turbo wastegated HX40 with a 60mm compressor and 64mm turbine. The turbo has a 18cm exhaust housing, which Hanlan admits is large, but spools perfectly with a small volume and short-charge tubing length.

“With the amount of nitrous I’m blowing through it, I need to have enough wastegate capability to handle all that extra exhaust gas that the HX40 can’t handle,” Hanlan says. “I have an ATS exhaust manifold with an external gate pedestal and that works pretty well.

“The HX40 is happy in its little zone of around 40 to 50 PSI, and then all the extra air comes from nitrous. The cool thing about that is the nitrous oxide is basically my intercooling system. I’m not using just a little bit, I’m using so much nitrous that it’s where I’m getting my air from, but also cooling my incoming air charge.”

For his 10.60 quarter-mile time, the engine produced 57-lbs. of boost from a 200 shot of nitrous. The Coalstang currently makes around 625-hp to the tires. Next year, with some further upgrades, Hanlan hopes to get the engine to around 800-850 horsepower in order to get into 8-second quarter-mile times at his race weight.

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].