Since I was a little kid, I’ve been into the muscle cars of the ‘60s and early ‘70s. Of course, in my day, they were already long gone off the showroom floor and Detroit was comparatively in a performance slump, which only added to muscle car popularity.

In those days, it seemed easy to know all the different engines, and anything from Chevrolet was no exception. There were only two engine groups that mattered if it had a bowtie on the front – the Gen I small block or an MKIV big block. The next important piece was the RPO (Regular Production Option) code that determined exactly which version of the engine went into which car.

Everyone knew the “original” RPO LT1, the hot Gen I small block 350 that was an option in the 1970-‘72 Corvette and Camaro. You also knew RPO L78 as one of the ground-pounding 396 big blocks from 1965-‘70. Then, there was the real monster, RPO LS6, the 454 cid beast first seen in the 1970 Chevelle. The cars were one thing, the engine was another, but it was the RPO code on the build sheet that determined what was sitting between the fenders.

Many years later, there was a hot new Chevy engine on the street – the now-famed LS. It caused some confusion at first, because everyone called it an LS, but it wasn’t an official engine designation by GM. What they are referring to is the Gen III Chevy small block produced from 1996 through 2007 and the Gen IV Chevy small block that was produced from 2005 through 2020.

The first one was the 5.7L Gen III small block in the 1997 Corvette. Its RPO code was LS1. For whatever reason, no one ever called it a small block Chevy, a 5.7L or a 350. Everyone latched on to the RPO code and every Gen III and Gen IV produced after was referred to as an LS. Only a handful of the Gen III and Gen IV engines actually have “LS” in their engine code.

Nonetheless, it is what it is, and the Gen III and Gen IV small block Chevy engine will forever be known as the LS. It’s easy to eliminate the confusion once you know where it stems from, and what tells the tale of how each of these LS engines is different and ultimately what modifications you can do to it starts with the RPO code.

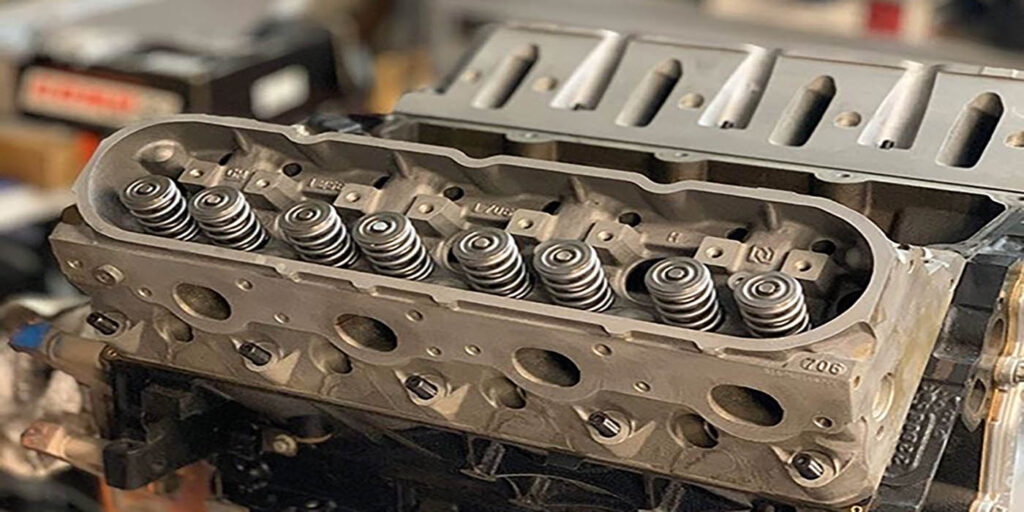

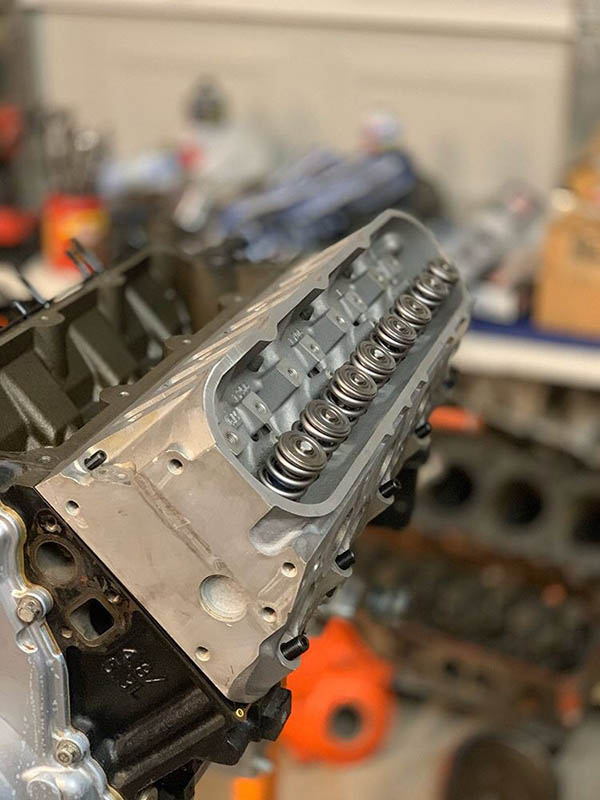

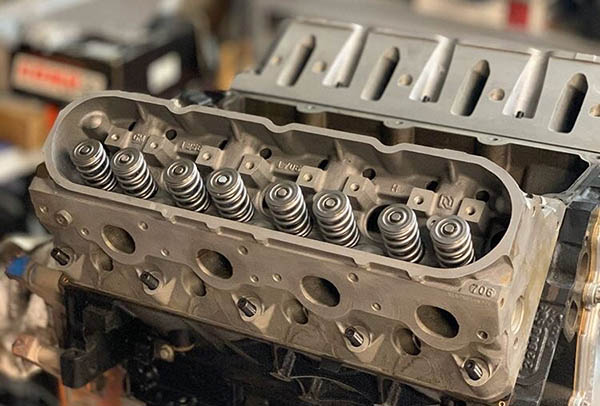

There were considerable differences between them over the years and since a majority of the modifications center around the cylinder heads, it’s nice to know what you’ve got to work with. We’ve pieced together a rundown on the basic setup of each different LS RPO as it came from the factory, but this is far from an end-all-be-all. There is much more involved in each of these engines when it comes to building one. Many of them, even with the same RPO code, came with different horsepower ratings. Even though the base engine was the same, different camshaft specs were frequently utilized depending on application, fuel systems varied, features such as Variable Valve Timing (VVT), and Active Fuel Management (AFM) were available on later engines, as well as LPG (Liquefied Petroleum Gas) and CNG (Compressed Natural Gas) fuel options.

What’s important here is that if you’re working on one, identifying the original engine will allow you to determine what you can or cannot do with it. That will yield the performance modifications you can do for any given engine, so you can set realistic expectations for the build and avoid unexpected difficulties.

RPO codes LR4, LM4, LM7 and L59 all utilized aluminum cylinder heads with 61cc combustion chambers, cathedral intake ports with 200cc runners, oval exhaust ports with 70cc runners, 1.890˝ intake valves, and 1.550˝ exhaust valves.

RPO L33, LS6 cylinder heads are aluminum with 65cc combustion chambers, cathedral intake ports with 210cc runners, D-Port exhaust with 75cc runners, 2.000˝ intake valves, and 1.550˝ exhaust valves.

RPO LS1 cylinder heads are aluminum with 67cc combustion chambers, cathedral intake ports with 200cc runners, oval exhaust ports with 70cc runners, 2.000˝ intake valves and 1.550˝ exhaust valves.

RPO LQ4 cylinder heads were iron (1999-2000) or aluminum (2001-2007) with 71cc combustion chambers, cathedral intake ports with 200cc runner (1999-2000) or 210cc runners (2001-2007), oval exhaust ports with 70cc runners (1999-2000), or D-port exhaust with 75cc runners (2001-2007), 2.000˝ intake valves and 1.550˝ exhaust valves.

RPO LQ9 cylinder heads are aluminum with 71cc combustion chambers, cathedral intake ports with 210cc runners, D-port exhaust with 75cc runners, 2.000˝ intake valves and 1.550˝ exhaust valves.

RPO codes L20, LY2, LY5, LC9, LH6, LH8, LH9, LMF, LMG, LS4, LS2, and LFA all featured aluminum cylinder heads with 65cc combustion chambers, cathedral intake ports with 210cc runners, D-port exhaust with 75cc runners, 2.000˝ intake valves and 1.575˝ exhaust valves.

For the head castings above, all of them can be CNC-ported to improve on flow and milled for higher compression. LS3 lightweight, hollow stem intake valves can be cut to fit the seats, and using the proper valves and better springs you can achieve a much higher rpm.

RPO codes L76, L77, L96, L98, LC8, LY6, L92, L94, and L9H utilized aluminum cylinder heads with 70cc combustion chambers, rectangle intake ports with 257cc runners, D-port exhaust with 87cc runners, 2.165˝ intake valves and 1.590˝ exhaust valves.

These heads can be CNC-ported to improve on flow and milled for higher compression as well, but the distinct advantage here is that the LS3 lightweight, hollow stem intake valves are the same size and will fit right in. Add better springs and you’re ready to go.

It’s also worthwhile to note that the LC8 and L9H cylinder heads were built with SIL-1 nitride intake valves and Brico 3010 valve seats. These engines were installed in trucks and vans that could run on e85, and some were optioned for LPG or CNG.

RPO LZ1 received AFM and VVT. The cylinder heads are aluminum with 65cc combustion chambers, cathedral intake ports with 210cc runners, D-port exhaust with 75cc runners, 2.000˝ intake valves and 1.575˝ exhaust valves.

LZ1 heads can be CNC-ported to improve on flow and milled for higher compression. LS3 lightweight, hollow stem intake valves can be cut to fit the seats, and better valve springs are a necessity for high RPM.

RPO L99 and LS3 cylinder heads are aluminum with 68cc combustion chambers, rectangle intake ports with 257cc runners, D-port exhaust with 87cc runners, 2.165˝ intake valves and 1.590˝ exhaust valves.

These heads can be CNC-ported to improve on flow and milled for higher compression. These heads are almost the same, but the L99 heads used a solid stem intake valve. The LS3 lightweight, hollow stem intake valves are the same size and will fit right in. Add better springs and you’re ready to go.

RPO LSA and LS9 cylinder heads are 356-T6 Rotocast aluminum with 69.8cc combustion chambers, rectangle intake ports with 259cc runners, D-port exhaust with 89cc runners, 2.165˝ intake valves and 1.590˝ exhaust valves.

LSA and LS9 heads were basically an improvent on the LS3 head, but for emissions and improved driveability they have a flow vane in the intake port. These heads can be CNC ported to remove the vane and improve airflow.

RPO LS7 cylinder heads are 356-T6 aluminum with 70cc CNC ported combustion chambers, raised square port, CNC ported intake ports with 259cc runners, D-port, CNC ported exhaust with 86cc runners, 2.205˝ intake valves and 1.610˝ exhaust valves.

Though they flow good in stock form, these heads can be milled and additional CNC porting can improve airflow. The valve guides also experience rapid wear, so it’s a good idea to replace them.

All LS cylinder heads have performance potential, but as with any aspect of engine building, the end goal determines the starting point. Aside from the material, combustion chamber size and port style, the valve size and weight can differ, and the valve angle is different on certain heads, as well as details such as valve cover bolt location. It just takes some digging to know your LS and stay a“head” of the game. EB