Whether you’re working on your own project car, or a customer’s vehicle, choosing the right engine is one of the most important decisions to make. By the end of this article, you’ll be armed with the knowledge to choose the right engine for you or help your customer to make the right decision for them.

What’s Trending?

It feels a bit cliché to say this, but it seems like the LS V8 engine family continues to reign supreme as “the king of engine swaps.” Spend more than 15 minutes at a car meet and you’ll probably see a few vehicles with an LS swap. It could be in anything from a classic muscle car to a modern import car, and everything in between. I myself have seen wild examples of LS swapped Porsche 993s, Honda S2000s, Toyota Supras, and some radical RWD converted Honda Civics.

Please forgive the analogy, but the LS could be thought of as “the Honda Civic of engine swaps.” How you ask? They’ve been around for a long time, they’re relatively inexpensive and there is an IMMENSE amount of aftermarket parts available for them. They come in various displacements and power levels, and you can find iron or aluminum blocks depending on the application. However, as technology continues to push forward, eventually this “king of engine swaps” will fall out of favor, right?

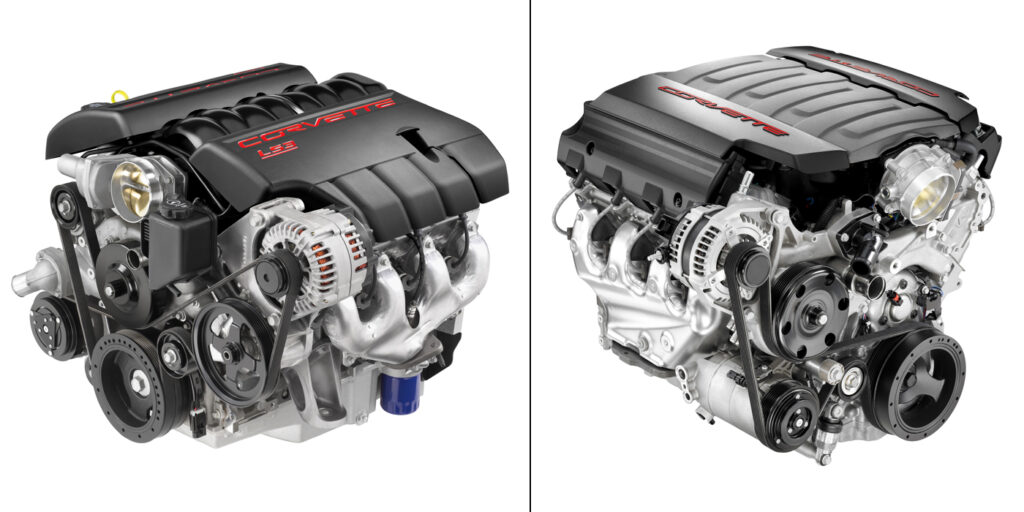

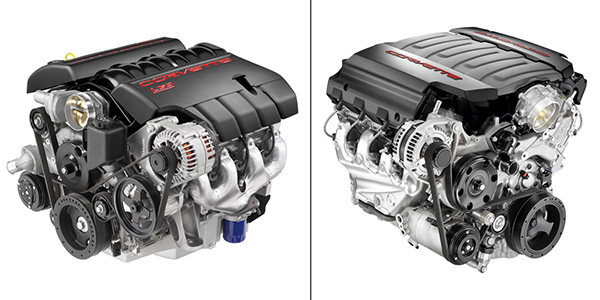

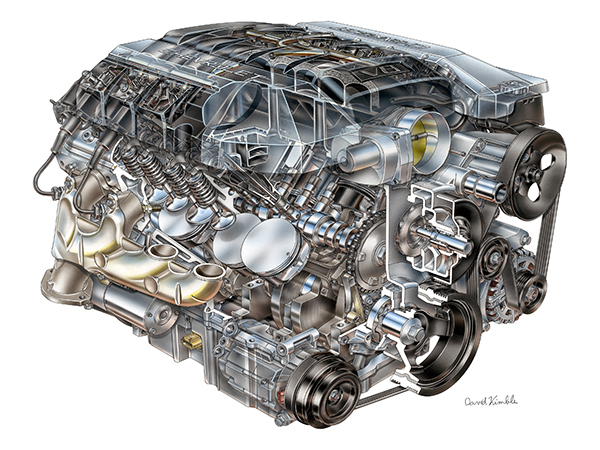

That remains to be seen, but the next logical successor to the LS would be the LT engine family. The LT was developed by GM to replace the LS in their cars and help the company meet ever-tightening emissions and fuel economy standards. These engines are newer, more advanced, and much more fuel efficient than their LS brethren, but this all comes with a cost – they’re more expensive.

Let’s dive into these two engine families, then we’ll discuss how to decide which is right for your (or your customers’) build.

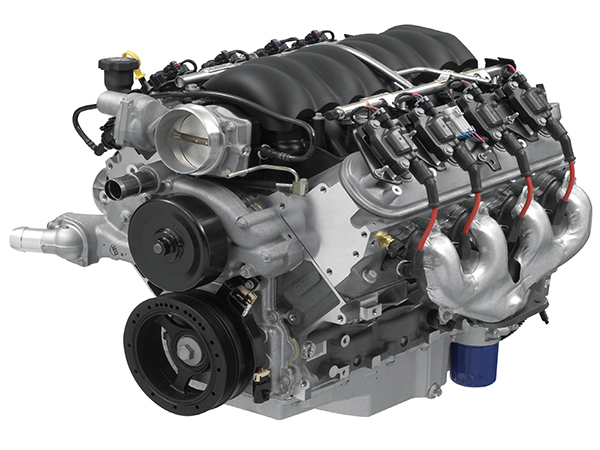

Long Live the King: The LS V8 Engine

Let’s look at some pros and cons for the LS engine family.

Pros:

- LS engines are plentiful and relatively inexpensive, both new and used

- Tremendous aftermarket parts support

- They utilize a rigid 6-bolt main cap design

- The skirted block design adds strength

- Port fuel injection isn’t prone to carbon buildup on the intake valves

- Engine blocks were constructed in aluminum and iron variants

Cons:

- The stock oil pump can cavitate above 6,000 rpm

- The skirted block design limits the ability to reduce windage in more conventional ways

- Port fuel injection isn’t as efficient as modern direct injection systems

- Fuel Management/Displacement on Demand systems aren’t known for their reliability or durability

- Variable valve timing systems were available, but offered limited camshaft adjustment range (typically around 20-degrees)

Bullet points aside, the market is simply saturated with LS engines and parts. The mighty LS has been at the top of the food chain for years now. It’s popularity, versatility and potential for big power has helped it rise above every other platform.

As such, there are companies which have started for the sole purpose of making stronger engine blocks to support huge horsepower figures, better flowing cylinder heads, intakes, and the list goes on and on. That popularity shows no signs of slowing down anytime soon.

“The LS is the king of swaps from here on out in my opinion,” says Mike Lough of Mike Lough Racing Engines in Oak Ridge, MO. “It has taken the role from the small block Chevy that the small block Chevy took when the Flathead Ford got pushed to the side.”

Mike isn’t alone in thinking this. Kyle Thompson of Thompson Motorsports also agreed.

“The LS is still, from our perspective, the most popular swap with the primary reasoning being the availability of the components and operating systems,” Thompson told us.

When asked to give us his top three reasons for choosing an LS over an LT, Lough said, “The aftermarket parts availability for the LS is heads and shoulders above the LT at this point as far as everything is concerned from intake to oil pan. The LS has been around longer, thus giving shops and enthusiasts an advantage of having more experience with them. For the end user, this gives them the chance to have more places to go to get their work done. Lastly, the LS is more available in OEM form (i.e., junkyards, replacement engines). There are probably millions of 5.3Ls and 6.0Ls out there in trucks because they have been in use since 1999.”

When asked to supply his top three reasons for an LS build over an LT, Thompson said, “The LS still has more widely available options and components from a broader group of suppliers. The knowledge base has grown with more install shops and tuners knowledgeable on the platform. And, it is a more widely recognized platform with a less complex feel and look, with more traditional appeal, and it fits the style of a wide range of platforms.”

So that’s it then, isn’t it? Case closed. The LS will reign supreme forever and nothing will ever top it? Not a chance. It’s had a long run, but technology moves fast in this world, so let’s take a look at the next GM engine – the LT.

Rising up the Ranks: The LT V8 Engine

Let’s begin again with some pros and cons for the LT engine family.

Pros:

- Rigid 6-bolt main cap design (similar to LS engines)

- Integrated PCV system and stop-start system

- Tremendous aftermarket parts support

- LT blocks are all-aluminum (except for 6.6L HD truck engines), which are more robust in design than the LS thanks to gusseted water jackets

- The engine block features eight oil sprayers which spray the bottom of the pistons (this allows for a cooler combustion process, higher compression, reduced friction, and more power)

- GM has addressed the LS windage problem and reduced the situation in the LT

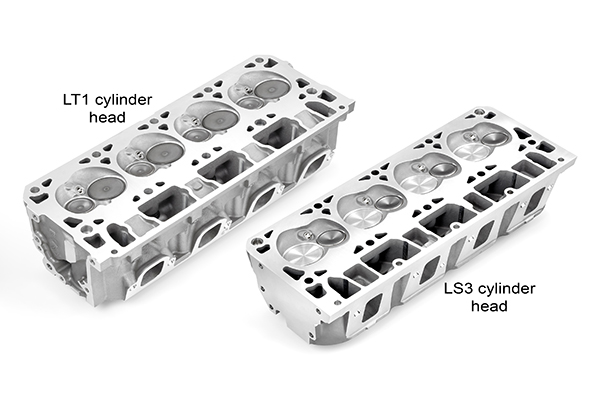

- Cylinder head bolt diameter increased from 11mm in the LS to 12mm in the LT

- Direct fuel injection offers improved efficiency and power

- Intake and exhaust valve position flipped from LS for optimum placement of direct injectors

- Variable valve timing system is improved and is always working, making timing changes for optimized performance/efficiency (camshaft adjustment range increased to 62-degrees)

- The newer Dynamic Fuel Management system is very progressive and hardly noticeable

Cons:

- LT engines tend to be more expensive than LS engines

- Aftermarket parts support lags behind the LS, though it is picking up

- Can be more challenging to install in some vehicles due to direct injection and lack of a belt-driven power steering pump

- Not flex-fuel capable “out of the box”

You may notice that the “pros” list is longer for the LT, that’s not by accident. This is simply the result of the more advanced engine design and technology. It’s the latest and greatest GM V8 on the market, and it’s improved over its predecessor. But – this all comes at an increased cost.

This may be the biggest limiting factor when it comes to this engine family – the added cost of parts and supporting mods. Many vehicles which were factory equipped with the LT also had electronic power steering, that could complicate the task of swapping that engine into a classic muscle car with hydraulic power steering. However, every problem has a solution.

When asked to give reasons for choosing an LT over an LS, Mike Lough said, “The short block components in an LT are stronger from the factory versus most LS. Many of them are 6.2L, which is a desirable size for the enthusiast to swap into a muscle car or an old truck restoration. The technology has advanced over the years with GM making improvements to the oiling, fueling and computer systems on the LT as well.”

Asking Kyle Thompson for his reasons for choosing an LT over an LS, he said, “The platform is capable of utilizing a lower grade fuel at a higher compression due to the efficiency of the direct injection system. In the sub-1,000 hp comparison, the power is generally smoother with more drivability. If the end user is looking for a more unique look that stands out from the crowd, the LT is still rare enough that it will draw the attention away from the now very commonly seen LS swap.”

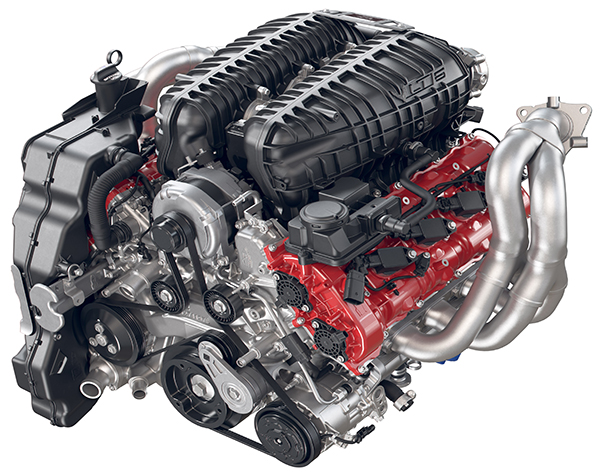

There’s one more thing that’s worth mentioning about the LT engine family – it’s still in development. GM will continue to develop and add more engines to the LT family, and that’s a very exciting thing! If you’ve looked at the spec sheet for the upcoming LT6 in the C8 Z06 you’ll see what I mean. This engine is a work of art, and the SOUND of that flat plane crank! One thing is for sure, the future looks bright for the LT engine family!

So, Who Wins?

The moment of truth arrives. How do you choose between the LS and the LT? That’s for you, or your customer, to decide. Look at all of the strengths and weaknesses of each engine, then weigh those against your power goals, the amount of aftermarket parts support, and ultimately, the budget.

Sure, the LT block might be stronger than the LS thanks to its gusseted water jackets, but that could be solved with an aftermarket LS block. The LT offers better fuel efficiency thanks to its direct injection, but carbon may build up on the intake valves. As with all things in life, it’s up to you to find the right balance for your needs, wants and goals.

Alternative Powerplants

While there’s seemingly little escape from the LS and LT hype, the market is still rich with other exciting engine options. Ford’s modular V8s (the 5.0L Coyote and 5.2L Voodoo) are also extremely popular in the aftermarket. Boasting advanced tech such as DOHC and VVT, these engines can be built from mild to wild and they sound great!

Mopar fans will be quick to remind you that the Hemi is still around, and it’s an absolute powerhouse! Hemi swaps are popular in the Jeep community since Jeep wouldn’t put a Hemi in from the factory – that is, until they released the 2021 Jeep Wrangler Rubicon 392. Let’s not forget the supercharged Hellcat and Hellephant engines, these extreme powerplants have been swapped into some wild cars!

So, rest easy, even if you decide that the LS or the LT is not the right engine for you, there are still plenty of choices out there. EB