Many aspects of old-school engine building, such as machining and measuring, are considered an art form or even black magic. Typically, those kinds of jobs within the shop require many years of experience, knowledge and feel for what you are doing.

However, as we’ve covered for many years now, advancements in the industry surrounding CNC machining have made some of those skills less crucial when it comes to physically doing the work – that is if you own one. Sure, you still need to know what it is you’re doing and why and what the outcome is you’re trying to achieve, but CNCs today take out human error and have allowed for tighter tolerances in today’s high-performance engine world.

Similarly, if you ask any engine builder how they go about measuring components such as pistons, rings, connecting rods, bearings, lifters, and other critical parts, the answer – 100 percent of the time – is by use of a micrometer and the proper feel. It’s definitely more art than science since each builder can do it slightly different.

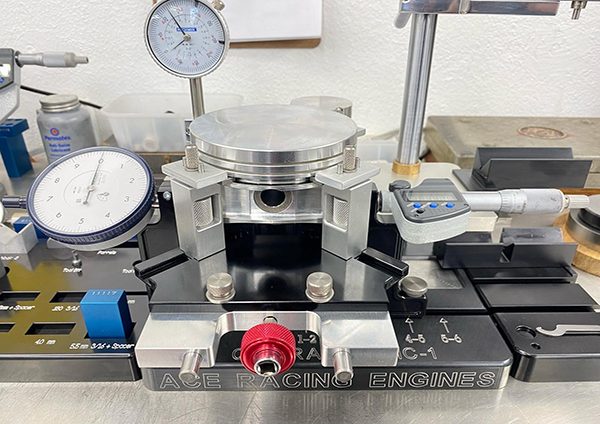

Over the past couple months, we kept hearing more and more engine builders tell us about Brad Lagman’s MC-1 measuring center and what a game changer it was. Obviously, we couldn’t ignore testimonials like that, so we spoke with Brad, owner of QMP Racing in Chatsworth, CA, about his new MC-1 measuring center and how it’s changing the way engine builders measure parts.

“I needed a better, more accurate way to measure pistons and make it repeatable,” Lagman says. “I’ve been working on this for two and a half years. I was initially doing it for myself, but as I was going along and posting about it, people wanted one and were asking if I was going to sell these? All of a sudden it was like boom, we’re going to start making these.”

Lagman’s MC-1 is a holistic approach specifically designed to eliminate human error and support the engine builder with value-added tooling that brings accuracy, repeatability, reproducibility and assurance to the high-performance engine building community. As more and more long-time experts in this industry become scarce, the need to replace their knowledge of touch and feel with instruments such as a micrometer is imperative.

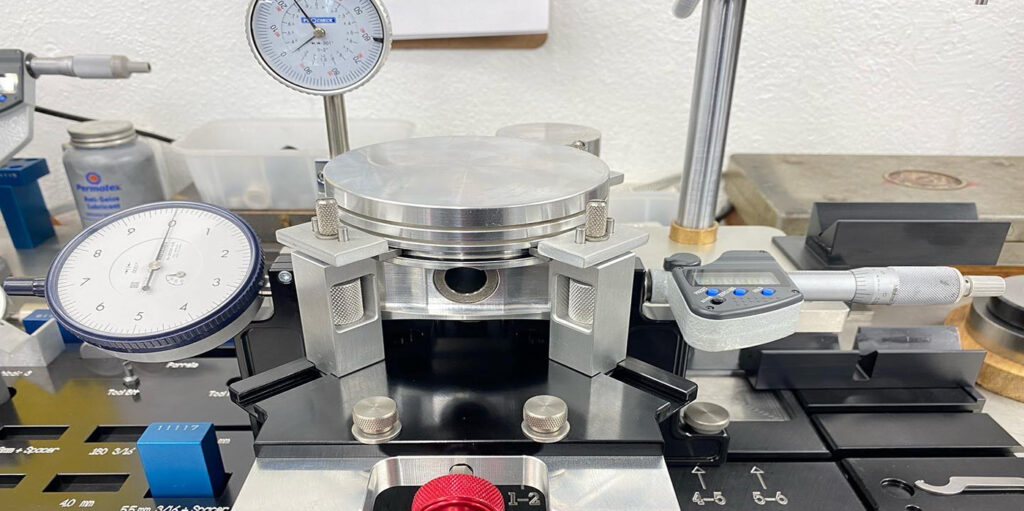

“Anyone I’ve talked to about [the MC-1], I’ve asked them how they currently measure pistons,” Lagman says. “Everybody’s response is it’s all feel of the micrometer. One hundred out of 100 people said that. What I’ve done with the MC-1 is put a dial indicator with a 3 newton spring on the other side of the micrometer. Now, when you zero it, it doesn’t matter how hard you turn the spindle of the micrometer, we’re using the spring of the dial indicator for repeatability. That’s how we’re getting a better, accurate measurement with more repeatability.”

The base unit MC-1 comes at a cost of $2,750 and includes the measuring center stand, a Mitutoyo digital micrometer, a heavy-spring dial indicator, a 2˝ Pro Gauge table height dial indicator, one round ring gauge, and a custom name engraving on the front. With the base model MC-1, builders can measure anything that’s round from 0˝-6˝ in diameter.

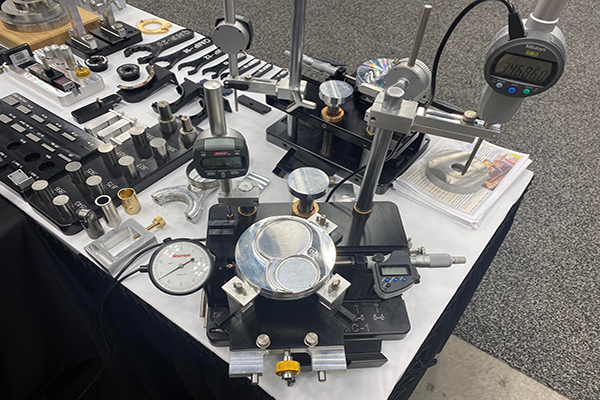

As Lagman continued to develop the MC-1, he knew what he created would be able to measure more than just pistons. He quickly began developing additional, bolt-on pieces that would allow for more capabilities if an engine builder wanted it.

“Not only can you measure pistons, but you can measure skirt diameter and taper,” he says. “From there, I’ve developed a number of attachments after the fact, and they are 100% bolt on. Regardless of whether you bought my first MC-1 or my latest MC-1, everything bolts on as you go, or as you see fit, or what fits your budget. I built this for guys like me. Not everybody’s ready to flop down $10,000 for a bunch of measuring stuff, but they might do the base model MC-1 and spend $2,750. Later on, they can decide to buy and add on additional measuring tools.”

The MC-1 offers increased measuring capabilities that no longer requires an expert’s feel for the micrometer and delivers even better accuracy. Lagman’s bolt-on pieces can allow engine builders to measure ring groove depth, compression height, dome thickness, and rod length. There’s also a centering fixture that holds the piston by the oil rails with a v-block and adjustable centering parallels to hold the piston exactly 90-degrees from the pin for precise measuring. There is a quick check fixture to measure lifter bushings – you can do 16 in just 2 minutes. There is also an accessory bracket to hold a Mitutoyo hole test micrometer to measure piston pin bores, rod pin bores, and rod bearing housing bores. There’s fixtures available to measure bearing thickness and a whole host of other tools to choose from depending on your needs.

The real kicker on top of what the MC-1 and its accessories offers is that it comes with and works directly with the Performance Trends Engine Build Log software for digitally keeping track of your builds with a simple push of a button.

“It was one of those things where you do something a certain way for so long and you think to yourself, there’s got to be a better way,” says QMP’s Mike Consolo. “Brad kept adapting the MC-1 like a LEGO set. Now it’s insane. Once you have the base model, you can literally buy anything along the way. Nothing becomes outdated. You never need a newer version to add to it. Everything is adaptable.

“I think that’s why a lot of people like it. It works really good and it’s super easy to use. Everybody’s got a little different feel of a mic and how much resistance it should have. The MC-1 takes all that out. You just zero out the MC-1 and put in the part you’re measuring and get your reading. Somebody off the street could measure a piston now no problem.”

In fact, that’s been a big benefit for Lagman himself. He no longer needs to be the person making these important measurements. He can be off doing other tasks while a younger, less experienced employee can handle the measuring.

“In my shop, because of the MC-1, I can have the kid who works for me measure pistons,” Lagman says. “I no longer have to measure the pistons. He can measure all this stuff because we took the feel out of it. He can do all that measuring and data record it and I’m working on something else that whole time. That’s how simplified it is.”

Since the MC-1 is modular, the options available to engine builders are endless. Again, the base unit MC-1 costs $2,750, while the catalog of bolt-on applications cost anywhere from $60 to $1,900. Currently, Lagman has sold a number of these measuring centers to both engine builders and manufacturers, and some units have even gone overseas. He told us the 2021 PRI show was a very successful week as well, and it seems he’s quickly changing the way we measure for the better.

The old way of measuring components with a mic by feel is over. The question now is are you going to adapt the new way or remain in the past? EB