Diesel of the Week is presented by

If you’ve been around high-performance vehicles long enough, you know that anything can happen. However, you don’t typically expect something to go wrong when your vehicle is parked. Justin Dignon certainly wasn’t expecting his truck to catch fire sitting in the driveway, but it did, and it fueled (pun intended) his most recent engine rebuild.

The truck is a 1981 Chevy crew cab long bed that has been in Justin’s family for 16 years. Sitting in the driveway untouched for two weeks, one day a faulty battery in the truck started an engine fire. Fortunately, Justin was home to put it out with a hose before he lost the whole truck and maybe even the house.

“Luckily I was home,” Dignon says. “As it was, the fire destroyed everything in the engine bay. The windshield fell in and burnt the seat, but nothing else inside got damaged.”

The 1981 Chevy truck was purchased by Justin’s dad in bone stock form when Justin was just 5 years old. Today, Justin is 21 and is an operating engineer with a passion for diesels, especially the 12-valve Cummins. The truck came with a 350 Chevy engine and a 700r4 transmission, and it had been a dream of Justin’s to turn this truck into a monster truck project that he and his dad could work on.

“It was something he and I used to work on here and there,” Dignon says. “I helped him as much as I could and we installed a 6-inch lift and put 36-inch tires on it. As I got older, I started getting more involved. I ended up taking over the build, gave it about an 11-inch total lift, put 38.5×15 super swamper boggers on it and 16.5×14 Eaton wheels.

“One of my friends and I put a Cummins in it at the end of high school when I was 17 or 18. I’ve been continuously working on it, making it better and better for about 4-5 years now.”

Justin has done enough work on the truck to this point that everybody in his town, Northport, NY, knows him for the truck, as do folks from 30 or 40 miles away. However, this recent engine fire meant an engine rebuild of the 1994 12-valve 5.9L Cummins.

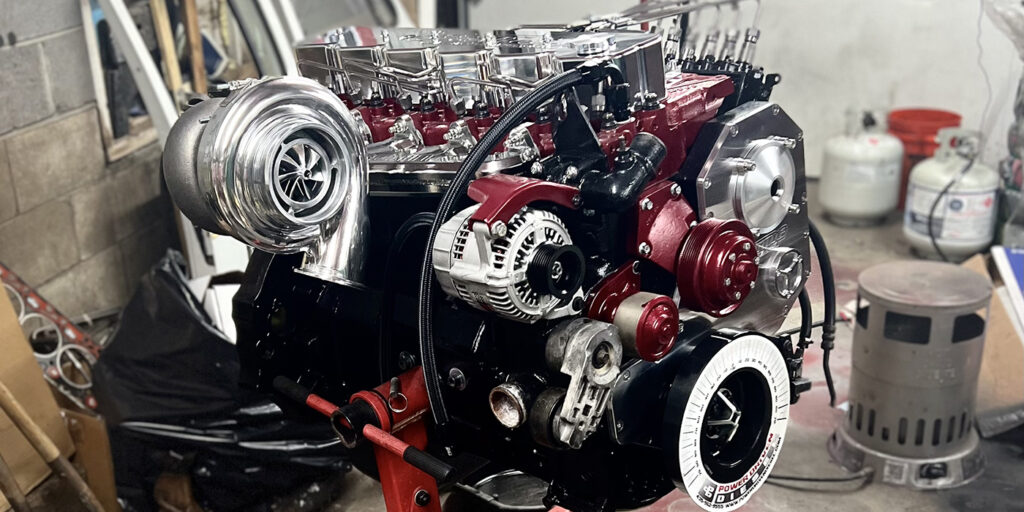

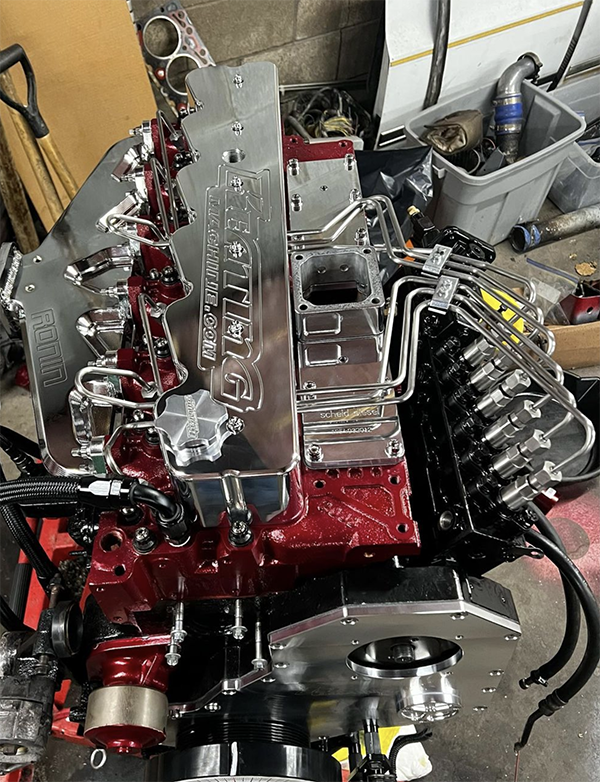

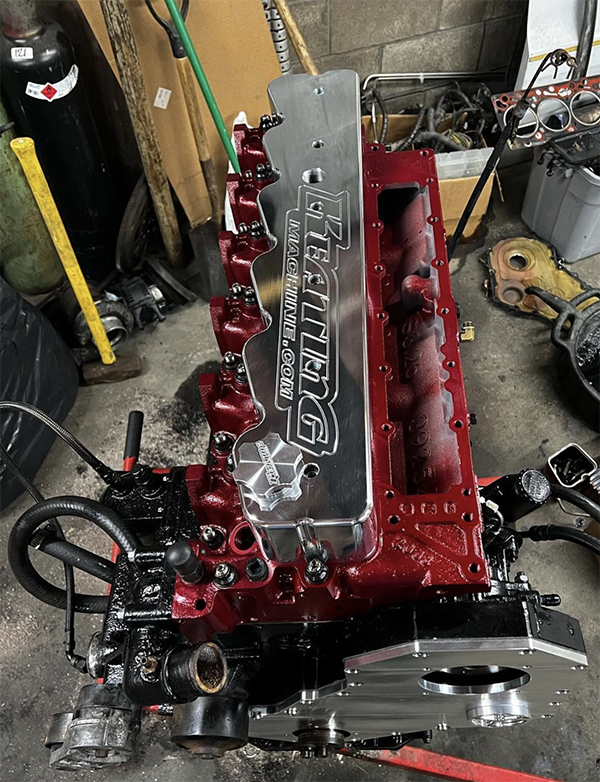

Justin started by putting a Power Driven Diesel Stage 1 ported and polished o-ringed head on the Cummins with upgraded top hat-style valve seals. It also has a Ronin Engineering T4 competition exhaust manifold and Fleece Performance stainless exhaust and turbo studs.

On the fuel side of things, the injectors are a set of 5x.016s Power Driven Diesel injectors in the engine now, but Justin says he’ll probably upgrade to 5x.018s soon. He also has 7mm delivery valves from Power Driven Diesel, a 4k GSK in the pump, XDP .093 delivery valve holders and .093 Scheid Diesel injection lines and intake plate. The pump has been maxed and balanced as well.

The Cummins also boasts a Keating Machine one-piece valve cover and timing cover, a Beans Diesel grid heater delete and tappet cover, Hamilton 165-lb. valve springs, Hamilton pushrods, a Hamilton 182/214 camshaft with a cam gear retainer and upgraded tappets, ARP 625 studs, Full Send Diesel heater core lines and turbo oil drain, a Fluidampr balancer, and DPC flexplate.

For the turbo, Justin opted for a Forced Inductions 472/87/.90. He resealed almost everything in the engine and it now has all stainless hardware.

“I’m hoping to make about 700 horsepower at the crank,” he says. “Considering the long wheel base, it’ll probably make half of what’s at the crank. I’d like to make a low EGT 700 hp and have room with the turbo to make more power.”

Since Justin is rebuilding the engine himself when he has time off of work, this won’t be one of the quickest rebuilds ever done, but it’ll put this 1981 Chevy back in a good place and plenty capable of performing during truck shows, cruises, and hauling things around town.

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].