Engine and Machine Shop Tips and Tricks

CHAMFER FILE

After surfacing heads, I like to chamfer the bolt holes and chambers. For the bolt holes, the common chamfering tool in a hand drill is great. For chambers, I’ve found that while a razor blade works excellent for aluminum, a file works best for iron. I use a chainsaw sharpening file with the end radius’d and polished. This way, if you inadvertently contact a seat with the blunt end, it won’t leave a mark. The same file works excellent for chamfering the bottoms of cylinder bores as well, without the risk of scratching a bore should you slip a little.

Ron Flood

Cedar Machine

North Branch, MN

PUT A LID ON IT

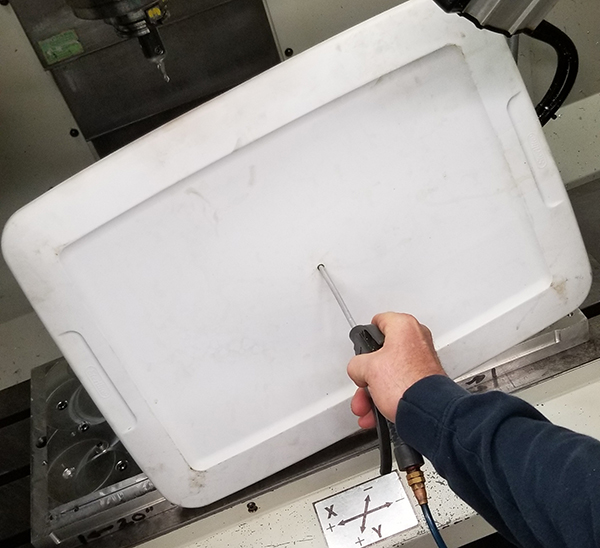

When machining on the CNC mill, it’s necessary to blow the flood coolant and chips off the parts for inspection. I tried a tool holder mounted fan, but it wouldn’t get all the chips and coolant out of the deeper areas. Using an air hose nozzle is required. However, no matter how careful I was using the air nozzle, I’d still get splashed with wet chips. Even stretching to reach thru the machine’s narrowly opened cabinet door would often result in a face full of coolant and chips.

I simply drilled a 1/4″ hole in the center of a plastic 23″ x 16″ tub lid for the air nozzle to slide through to make a splash shield. I guide the top edge with my left hand, and hold the air nozzle with my right hand, moving the lid left and right and in and out as needed. The plastic lid doesn’t scratch the work piece and is durable and easy to clean. A magnetic hook on the CNC cabinet keeps it handy, ready to use. I made another for our vat wash-down area’s air hose nozzle for use when cleaning/blowing out bolt holes in blocks, etc.

Tom Nichols

Automotive Machine & Supply

Joshua. TX

LS CRANK I.D.

The 5.3L and 6.0L LS engines use the same stroke crankshaft with the same casting number. But the balance is different on the cranks for the different bore size pistons. There is a quick way to determine which crank you have. If you look at the front and rear rod throws, the 6.0L crankshaft has a lightening hole and the 5.3L crankshaft is solid.

Nick Jones

Automotive Machine

Fraser, MI

CATTLE CONTROLLER

For anyone that has ever stepped away while they were filling their coolant tank, I have the perfect solution to keep from spending a portion of your day from cleaning up the mess. The simple installation of a cattle waterer, which keeps the level constant in any cattle watering trough, will be sure to cure your problem. I know firsthand how easy it is to step away and get distracted or step away just for a second and get sidetracked, and when you come back there is water all over the floor.

Adney Brown

Performance Crankshaft

Ferndale, MI

BEAT THE HEAT

Too much heat can destroy an engine. Gas engines are designed to operate between 190-220 degrees F, hotter than 220 and you’ve got an overheat situation. As an engine overheats, aluminum material will begin to warp, expand and even crack. A warped cylinder head could separate from the engine block creating a leak in the head gasket. A leaky head gasket will cause the engine to start burning oil and coolant. In extreme overheat conditions, crank and cam bearings become galled and can cause a catastrophic rotating assembly failure.

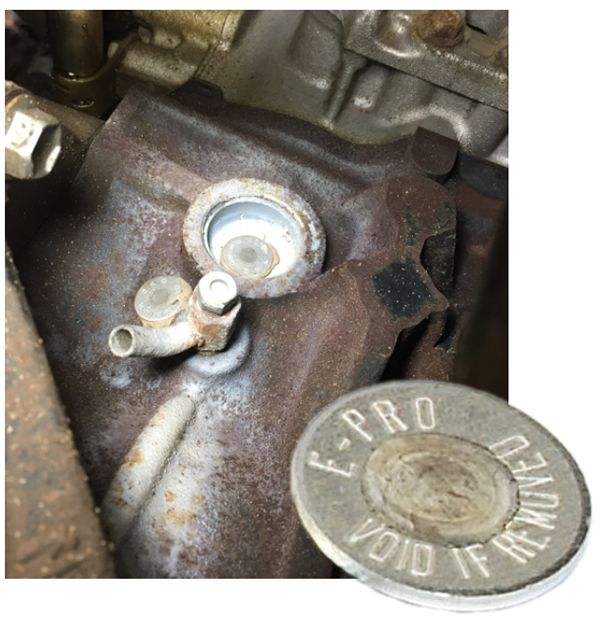

Here’s a tip to protect you and your fresh build from an overheat failure. Make it clear, in writing, that your customer is responsible for replacing the belts, hoses, thermostat and water pump. Ensure the customer has professionally cleaned the radiators, including oil coolers and the heater core. Demand that your customer maintain service records including oil and coolant changes. To monitor future overheating situations, always install heat tabs on the cylinder heads and block. Install the tabs in an area that is in direct contact with the engine coolant. Tabs melt out around 250o F. It’s a good insurance practice to install tabs on all rebuilt heads and blocks and be sure to let the customer know where they are installed, and that removal or melt-out conditions will void your warranty.

Steve Rich

Sterling Bearing, Inc.

N. Kansas City, MO

SPECIAL AND NUMBERED STONES

If I need to touchup a seat after machining, even on the Serdi, I go to my numbered stones and holders. I have three numbered holders and always use them as pairs. Sometimes if I just need a quick touch up and the stone is good, I won’t need to dress it. If it does need dressing it will generally take less to clean it up so less dust. I keep dedicated stones for different heads I work on regularly and it speeds up the job. I just did a 466 JD and had the correct stone, so the touch up went fast.

Randy Torvinen

Torvinen’s Machine

Menahga, MN