For many years, cylinder honing has often been represented as a routine and simple procedure, but that’s only true in the hands of a professional engine builder. Modern scientific knowledge on the subject is miles ahead of old-school techniques, and today’s information-overloaded internet has many novice builders falling victim to misconceptions on the subject. The true complexity of honing and its importance is not always reflected as it should be.

Professional builders have the experience and knowledge to recognize when and where to use various cylinder honing techniques. When employing old-school methods, such as a traditional ball-hone on the end of a drill, a couple dozen well-timed strokes from an expert can yield exceptional results – certainly adequate for the “average” engine build for a typical driver-style classic car. But that’s where old school ends.

When it comes to today’s high-performance, high-horsepower engines, it’s out with the old and in with the new, and there’s no exception in the case of the popular LS engine. Modern honing techniques are as much a performance concern as they are part of engine design, and that’s thanks to the much tighter tolerances and specifications engines need these days.

There’s no question that engine efficiency has seen drastic improvements over the past few decades – a result of the need for reduced emissions and improved fuel economy – but the technology behind it goes beyond the daily driver and aligns directly with high-performance engine building.

While it shouldn’t be considered a more important aspect than any other, the cylinder hone is a factor by itself that can have a drastic effect on end performance. Honing is the art of surface preparation, which yields the proper crosshatch pattern and roughness for any specific application. Many techniques have been utilized in the past, but modern machining follows a stricter path.

“Remember, specs weren’t what they are today, and that’s why today honing is honing and boring is boring,” says Bob Dolder of Sunnen. “You don’t want to go to the next oversize with honing anymore, you at least want to leave a minimum of .005” to hone out of a cylinder. What you’re after with honing is removing the tool marks and making the cylinder as perfect as you can make it. That’s where you get your geometry, surface finish and cross hatch angle, those are all critical, and you get that specification, not from the honing company, but from the ring manufacturer.”

The start of any engine build is considering the big picture – the ultimate application of the engine – and the implications of it become even more relevant when you weigh in the importance of the cylinder hone. Once the decision of pistons and rings has been made, it starts to get real, and with the rings come a critical set of specifications from the manufacturer. They will provide hone specifications based on the use of the engine, and they’ll need answers to multiple questions that affect them. Is it a street or racing application? What type of fuel will you be running? What type of oil? The answers to these questions and more will determine the hone specifications.

“For years, everyone was seeking the smoothest finish they could get,” says Ed Kiebler of Rottler Manufacturing. “The problem is you reduce friction, but you sacrifice sealing. When you get into turbo, blower and nitrous motors, your combustion pressures go up, and you’re feeding these engines unbelievable amounts of fuel, and what happens is, with these real fine finishes, you’re washing the oil off the cylinder walls. The rings need oil to seal.”

If you’re wondering why a ring manufacturer should provide these specifications, we’ll take a brief look at what they do. They are experts in the field of tribology, which is the study of friction, wear and lubrication. Almost half of all engine friction comes from the contact between the piston rings and cylinder walls, making this angle of science the primary study of ring manufacturers. One of the many complexities is the relationship between ring material and construction to the lubrication on the cylinder walls, which goes hand-in-hand with honing, so if you’re going to make a successful piston ring, you’re going to be an expert on these two subjects.

For many years, single step honing (aka old school), was the way it was done. The visible result and the way we measured the success of it was in the crosshatch angle. This is a very important angle as it allows the oil coverage to spread across the entire cylinder wall.

“It also enhances ring rotation,” Kiebler says. “If you get too steep of a crosshatch angle, the rings will spin too quickly, and it will wear them out. If the crosshatch angle is too flat, then what happens is they will start to skate because the oil pulls in a flatter crosshatch.”

The crosshatch angle is something you can see, but the problem is what we couldn’t see – the resulting surface finish made up of peaks and valleys of similar height and depth. The parameters of the surface texture in this type of hone were measured in Average Roughness (Ra). During break-in, the higher peaks are worn down, leaving mostly smooth surfaces with valleys to retain engine oil.

The drawback to single-stage honing is the break-in process is relatively uncontrolled and can create performance-affecting sealing issues as well as debris. Even in the ‘60s, performance and emission standards began to tighten the noose around the neck of auto manufacturers, and a new process was developed called plateau honing, the purpose of which was to reduce break-in and improve engine sealing.

“Where we used to try to get really fine finishes to reduce friction, utilizing Rk parameters, now we try to get a really fine finish on the plateau, what we call the Rpk measurement, since that is what the ring sees,” Kiebler says. “We then try to have deep valleys on either side of the plateau to hold the oil that will seal the rings.”

Plateau honing consists of coarse honing to create the valleys and smooth honing to create the peaks. Over the next few decades, the science of it advanced it into one of the more relevant technologies of engine design. In conjunction with this new technology, new parameters were developed to accurately measure the surface finish, since an average was no longer adequate.

Often referred to as just Rk specifications, the new specifications were Core Roughness Depth (Rk), which is the roughness of the base surface of the cylinder wall, Peak Reduced Average Roughness (Rpk), which indicates the average peak height, and the Reduced Average Valley Depth (Rvk).

Ring manufacturers know the key part that engine oil plays in the actual sealing between the ring and cylinder wall, and as part of their tribology research, they know that for proper sealing, you not only must have the proper oil type and viscosity, but it needs to be the proper amount in the proper locations at the proper time.

-Bob Dolder, Sunnen

All these factors lead to different combinations of Rk numbers having significant performance affects in every type of engine from mass production engines to all forms of racing – proof that different engine applications require different honing parameters.

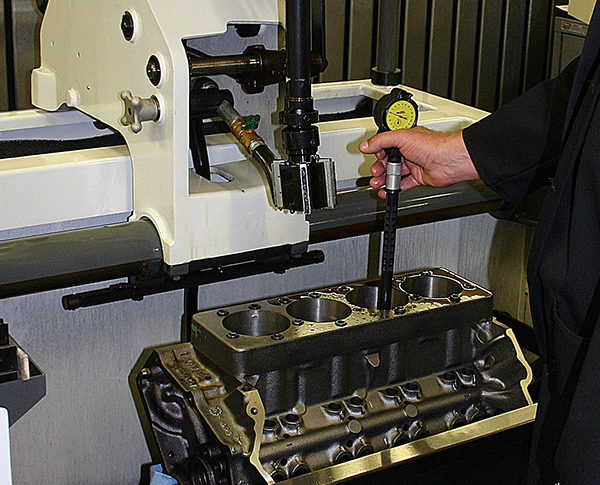

Once equipped with honing specifications, the next step is for a machinist to determine how to perform the hone to attain them. Rk measurements require the use of a profilometer, which is a measuring device that will provide a tracing of surface characteristics to the accuracy of a millionth of an inch.

But there’s still more to the process than just honing and measuring. “To do it right, you need to keep a log for each different type of block,” Sunnen’s Dolder says. “Take a hardness test and create a recipe for that block and hardness.”

Not only can blocks be a different hardness depending on manufacturing tolerances, but the older a block gets and the harder it is driven, the harder the metal gets. “Checking the hardness and determining how to perform the hone to meet the specification is up to the machinist,” he says. “There can be multiple different ways to hone an LS, depending on where and when it was produced.”

Different hardness will require a different grit of hone, and while it can take a lot of time to determine the “recipe” for each individual block, by keeping a logbook, over time, the type of block, hardness and the desired hone parameters will start to fill in the blanks, and it’ll become a much more efficient process.

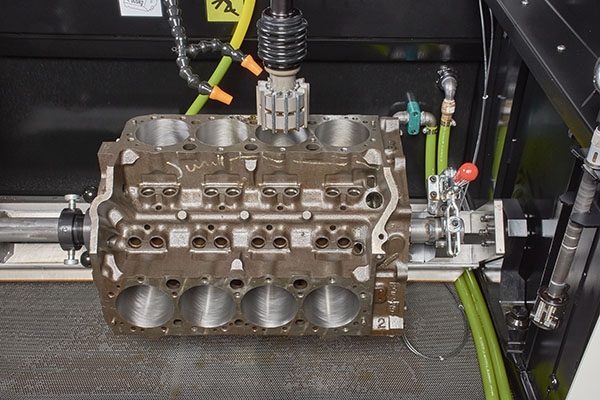

A profilometer and hardness tester are the two primary tools you’ll need, along with a quality dial bore gauge and torque plates. “Torque plates should definitely be used during honing,” Dolder says. “Manufacturers use torque plates on new blocks because of their importance.”

New honing machines are programmable for multiple different hones, and can store multiple different programs, another way engine shops can benefit from a logbook of formulas, but ultimately the responsibility still falls on the machinist.

“It’s up to the machinist to look at the recommended Rk values, then it’s a combination of what abrasives you’re going to use and how you’re going to set the machine up to be able to go from rough to finish,” Dolder says. “In some cases, it’s a two-step process. In other cases, it’s a three-step process. It just depends on what those measurements are and how you get there. That’s where the machinist needs to think and understand how the machine operates and what it can do and take everything else into account.”

The proper tooling is another aspect of modern technology that is as important as any other. “For years, people used two-stone hone heads,” Kiebler says. “Six-stone hone heads are probably the most optimum and provide true roundness. Between the six-stone hone heads and the new surface finish parameters, we’re really finding some horsepower gains. It’s a lot of fun.

“I’m even putting plateau finishes on street-driven cars, because I see the advantage. I’ll never notice the horsepower, but I’m still doing it because it helps the longevity of the engine.”

It’s been common over the years to think of the process as easy, but it’s been anything but in more recent years. The seemingly routine, old-school methods could only guarantee success in the hands of a professional, and a reflection of a modern-day engine builder expertise is seen in the science of new honing methods. EB