Diesel of the Week is presented by

We can confidently say that Jeff McCord of LinCo Diesel Performance knows his way around a diesel engine. He’s made a name for himself building some pretty badass diesel engines for customers, a few of which have been featured in our Diesel of the Week series in years prior. He also won our America’s Best (Diesel) Engine Shop award in 2021, has shown us the difference between a Mild and a Wild engine build at his shop, and given engine builders a load of useful educational content via our LinCo Lessons series.

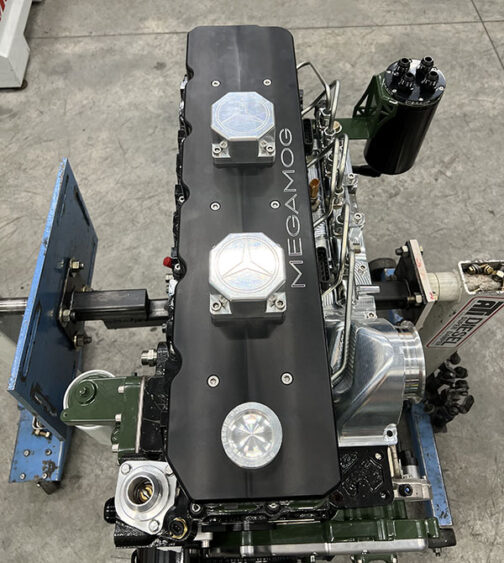

It seems like he’s always got something cooking, and recently it’s been no different. McCord reached out to us last week to tell us about a rather unique project he just finished at the shop – a specialized 5.9L Cummins engine he built for a custom 1965 Mercedes Unimog multi-purpose truck.

The vehicle itself is rather distinctive, but even more so are the conditions it will be driven in. The Unimog is being built by Craven Performance for a client who owns a private ski-ranch in central Colorado. The ~$500,000 truck will be operating from around 6,000 to 11,500 ft. in elevation. We’ll have to wait until this year’s SEMA show to get a proper look at the cab, but McCord already has the engine built up and ready to dive into.

Being that it will be operating at such high altitudes, the first thing to consider was the thin air the Cummins would be operating in. For that reason, the team at LinCo decided on a 5.9L bored .040” over rather than a 6.7L to keep the displacement low and ran 01’-02’ 24 valve high-output cast pistons.

“Those have the highest compression of any factory piston,” McCord says. “We wanted the highest static compression because of the altitude it will be running at, so we’ll put about 17.2:1 to 17.5:1 for the compression ratio. And we used a Hamilton 178/208 camshaft for the efficiency in the low-end torque since this thing will be need to keep momentum climbing up some deep packed snow. It’s a steel camshaft that we line bored and put cam bearings all the way throughout.”

The engine has a Beans Machine 12mm girdle, it was line honed and decked, and boasts LinCo’s own LDP Reman head with stock-sized Inconel valves. D&J 115-lb. valve springs with titanium retainers keep the valves closed.

It also features Total Seal gapless rings, Clevite H-series bearings, a Fluidampr balancer, a Kingspeed billet timing cover and intake horn, LDP’s 6.7L-style billet intake plate, and a JEGs Electric water pump.

“It’s got Boostline forged connecting rods in it, a factory 5.9L crank that’s been keyed and balanced, Hamilton pushrods, Fleece billet valve bridges, a Cometic MLX head gasket, and ARP 625 head studs.”

On the air side of things, McCord went with a Diesel Power Source Turbonator, which is a mechanical, variable geometry turbine housing.

“The drive pressure actually moves the veins, so when everything is closed and there’s no drive pressure applied to the actuator, it’s like a .50 AR ratio, so it’s a super tight housing that spools quick. Then, as drive pressure builds, it pushes on the wastegate actuator head and works the veins just like an electronic actuator would. It regulates itself off drive, and it’s perfect for this setup.”

The complete setup took a bit of engineering to get everything right, but a Turbonator mechanical VGT housing on a DPS T3 manifold was eventually decided upon. Paired with the Turbonator housing is a 5-blade 362/68 high pressure charger. For the atmospheric, it’s a Stainless Diesel-built 5-blade S480/93 with a 1.0 T4 housing in an effort to keep everything as tight-spooling as possible.

As far as fuel goes, S&S spec’d out the entire setup. The team went with 200% over injectors, a 12mm CP3 pump, and a 6.7L fuel rail, sensor and relief valve.

The Cummins powerplant hasn’t been dyno’d yet, but McCord expects the engine to make 1,200 horsepower, or around 600 horsepower in the high altitudes and operating conditions it will be working in. Paired with a 6-speed Allison transmission, this beast will have more than enough power to carry its passengers up the ski slope.

To see the finished product, make sure to stop by the Craven Performance booth at the 2023 SEMA show!

Diesel of the Week is sponsored by AMSOIL. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].