Engine of the Week is presented by

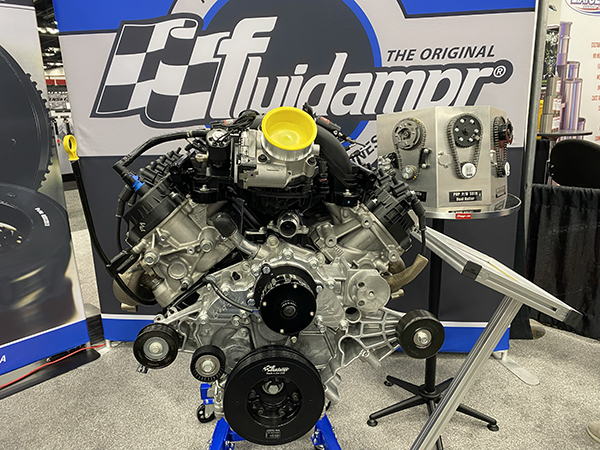

While at the 2022 PRI Show, we swung by the Fluidampr booth to say hi to a few folks, and we found ourselves looking over a nitrous-powered 7.3L Ford Godzilla engine on display. As it turned out, Paul Svinicki, the engine builder behind this Godzilla build, was standing nearby, and he was kind enough to fill us in on the details.

Paul has been in the industry for 35 years. His shop, Paul’s High Performance, located in Jackson, MI, has been an area staple for 27 years now.

“We do everything from the 1950s to 2022,” Svinicki says. “We have older cars, newer cars, fuel injected cars, and so on. Aside from engine work, we’ll also get into steering, suspension, brakes, wiring – whatever the car needs. Not a lot of shops are that versatile, but it’s what we like to do. We focus on domestic cars and engines, no foreign cars.”

Paul also told us his shop has a chassis dyno and does tuning work, as well as custom carb work. However, when it comes to machine work, Paul’s High Performance only has a mill and a lathe for simple customization work. The larger machining operations for engine builds get sent out to other shops.

“I have three employees currently,” Svinicki told us. “I’m 66, so I’d like to not work 80 hours a week, plus we race and go to the track. We prove our work on this Godzilla engine program. Our car has over 350 passes. I don’t think there’s many people with 350 passes on their car with a Godzilla engine. We’re at the track, we’re testing, and we go to major events. We don’t do private stuff to say we did this or that. We do it right in front of everybody. We like the car to speak for itself.”

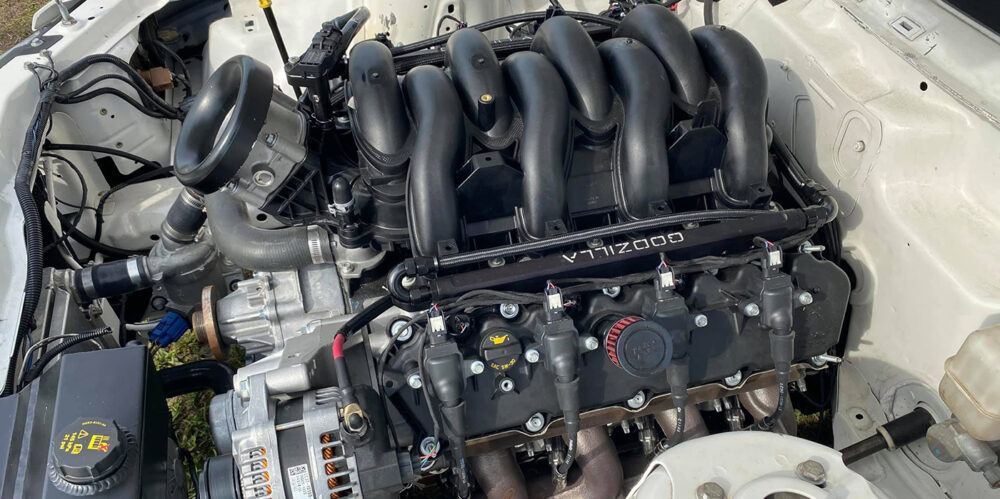

The Godzilla engine in question initially came from a production truck and Paul wanted to see what the engine would handle.

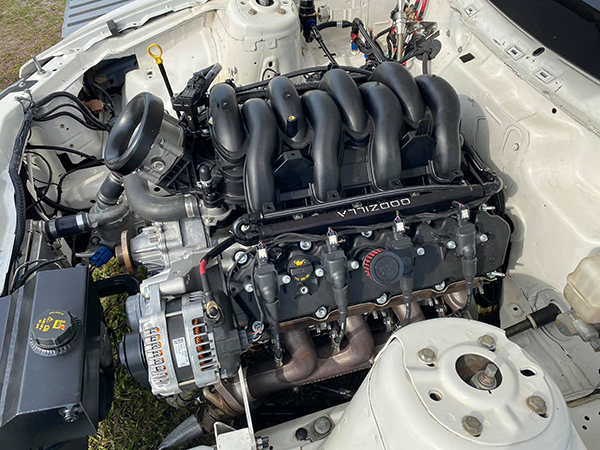

“With a production Godzilla engine, we were the first in the 10s, the first in the 9s and the first in the 8s,” Svinicki says about their ETs. “Now, those weren’t all stock components. Currently, we’ve run a best 8.83 at 152 mph in a 3,400-lb., 2010 Cobra Jet. To get there, it has a custom camshaft, custom valve springs, forged Mahle pistons, Molnar rods, stock factory bearings, stock factory rings, and a stock factory bore. We do have an electric water pump on it and headers. To get the best performance out of it, we wanted to go nitrous and we wanted to do a dry kit.

“We’ve never really worked with a dry kit before, so Nitrous Outlet has been very instrumental working with us and getting this all to work correctly. You have to have the right components and you have to have a partner. We spray nitrous in the throttle body and then we have a direct injection kit that we bring in 7/10ths of a second later. We make our own atmosphere, so it’s very easy on hot, hot days. The nitrous is really good for making the same power all the time.”

Ford’s Godzilla engine has been gaining steam amongst engine builders and racers alike who want to see what the platform can handle and do, but not many folks are utilizing nitrous with it.

“Everybody’s doing turbos and superchargers, but we’ve used nitrous before,” he says. “However, to do a dry kit and then have control, we’re using FuelTech. They have the best control system, we feel, on the market. It’s fly-by-wire, so we’re able to monitor how it comes in, when it comes in and it’s just a smooth hit. Yes, when you leave off the trans brake, it’s wheelieing. We get 1.16-second 60-foots and so it leaves hard.”

According to Paul, the crankshaft is still a stock piece, but the shop balanced it and utilized a Fluidampr damper to help with engine harmonics. His shop also made the electric water pump plate and upgraded the timing chain.

“We’ve got block off plates,” he says. “These engines have a great big oil cooler. It takes 7” of room. Ours is 3”, so it bolts right on with the same o-ring and same bolts. The other thing we do is our own timing set. We wanted to get rid of the VCT. For racing applications, the Ford production stuff is good, but this is not in a truck. With 1,104 ft.-lbs. of torque and a 1,100 horsepower, the stock components are not designed for it. We ended up coming up with a dual roller timing chain set that’s adjustable.”

With one of the fastest Godzilla engines around, Paul’s High Performance continues to push the development of this newer engine platform. It’ll be interesting to see how far the Godzilla can go.

Engine of the Week is sponsored by PennGrade Motor Oil, Elring – Das Original and NPW Companies. If you have an engine you’d like to highlight in this series, please email Engine Builder Editor Greg Jones at [email protected].